System and method for determining concentration of carbon dioxide in industrial smoke

A technology of industrial flue gas and carbon dioxide, which is applied in the direction of measuring devices, preparation of test samples, material analysis through optical means, etc., can solve the problems of poor applicability, low accuracy and low processing capacity of online large batches, and achieve reliable The basis of the method, the effect of meeting the traceability requirements of the quantity value, and improving the repeatability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

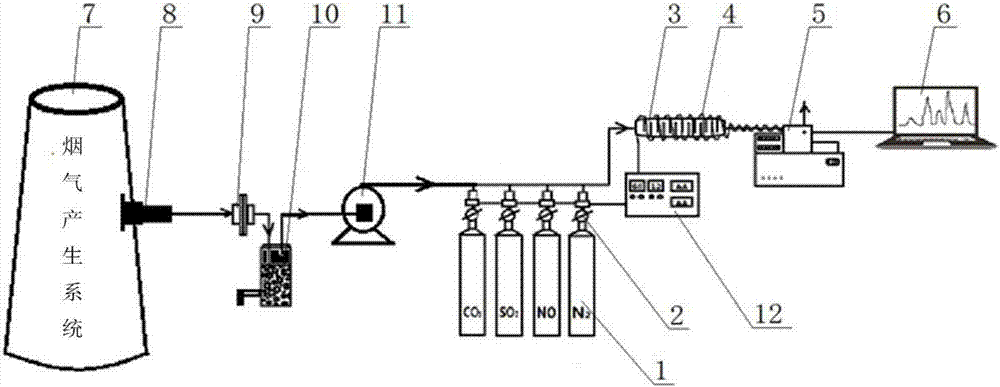

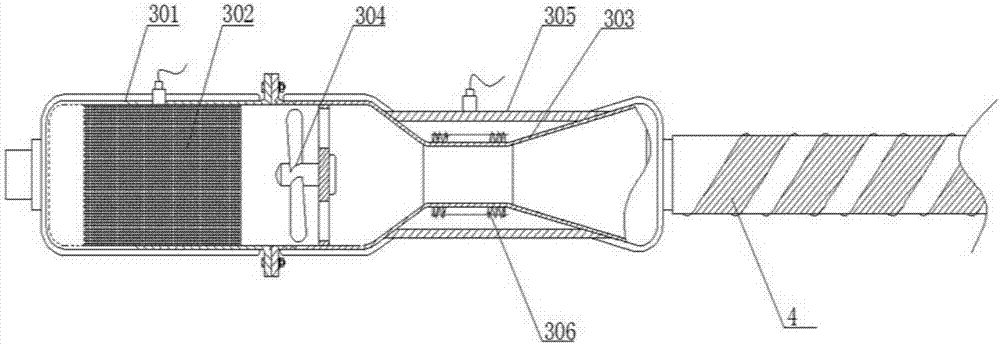

[0045] A carbon dioxide concentration detection system in industrial flue gas, such as figure 1 As shown, the system includes a standard gas storage tank 1, a gas mixing heating pool 3 connected to the standard gas storage tank 1 through a ventilation line, and an IGS gas infrared analyzer 5 connected to the gas mixing heating pool 3 through a ventilation line , the IGS gas infrared analyzer 5 is electrically connected to the signal input end of the data acquisition device 6; the carbon dioxide concentration detection system in the industrial flue gas also includes an industrial flue gas generation system 7, which is connected to the industrial flue gas generation system 7 Through the sampling gun 8, the dust filter 9 connected with the sampling gun 8 through the vent line, the condenser 10 connected with the dust filter 9 through the vent line, the sampling pump 11 connected with the condenser 10 through the vent line, The gas mixing heating pool 3 connected with the samplin...

Embodiment 2

[0051] One of the methods for detecting carbon dioxide concentration in industrial flue gas by the carbon dioxide concentration detection system in industrial flue gas described in embodiment 1 may further comprise the steps:

[0052] (1) Turn on the controller, set the temperature value on the controller, and heat the gas mixing heating pool in the carbon dioxide concentration detection system and the ventilation pipeline connecting the gas mixing heating pool and the IGE gas infrared analyzer to 155 through the electric heating belt. ±5°C constant temperature, and set the measurement temperature of the IGS gas infrared analyzer to 155±5°C; set the flow rate value of each standard gas on the controller, and the controller controls the gas outlet of the standard gas storage tank according to the set value The gas mass flowmeter can control the gas flow;

[0053] (2) To establish a standard fitting working curve, the steps are as follows:

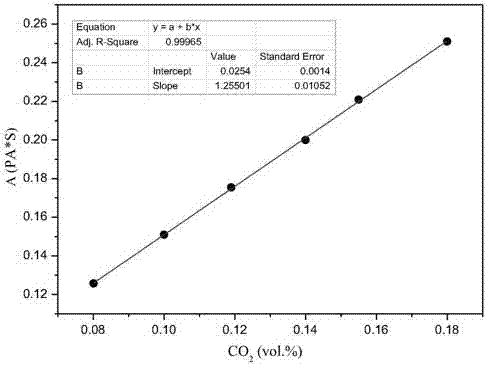

[0054] ①. Standard gas CO in the car...

Embodiment 3

[0067] The second method for detecting the concentration of carbon dioxide in industrial flue gas by using the carbon dioxide concentration detection system in industrial flue gas described in Example 1 comprises the following steps:

[0068] The same as Example 2 will not be repeated, and the difference is: the flue gas produced by the gas industry (Zhengzhou gas-fired power plant) is collected, and after the treatment, it is passed into the gas mixing heating pool, and the industrial smoke in the gas mixing heating pool The gas is passed into the IGS gas infrared analyzer at a flow rate of 2000ml / min for detection and analysis, and the detection is repeated three times. Under this condition, the average value of the characteristic absorption peak area of carbon dioxide in industrial flue gas is 0.15341PA*S;

[0069] Then the obtained results were substituted into the standard fitting working curve equation described in step (2) of Example 2, and the volume concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com