flakes

A sheet-like, polyurethane resin technology, used in fiber processing, textiles and papermaking, etc., can solve the problems of low polyurethane content, hard hand feel, significant changes, etc., to achieve excellent durability and light resistance, beautiful surface appearance , Soft wrinkle recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

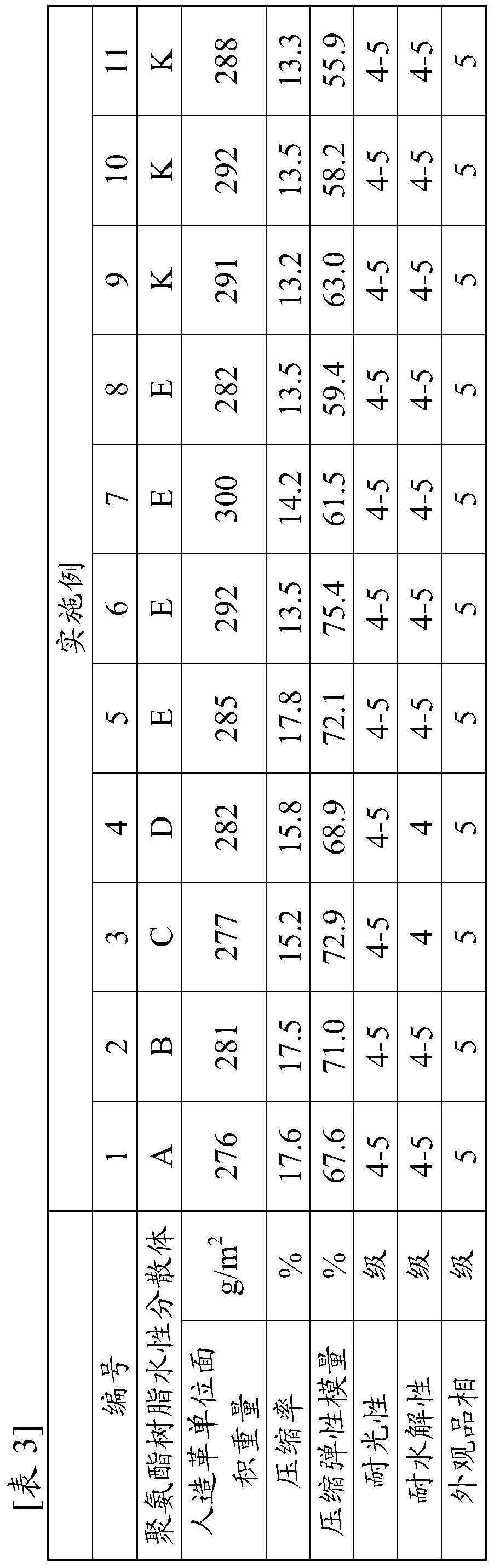

[0213] Next, the sheet-shaped article of the present invention and its manufacturing method will be described in further detail using examples, but the present invention is not limited to these examples.

[0214] [Evaluation method]

[0215] (1) The feel of the sheet:

[0216] A. Compression ratio

[0217] As an indicator of the flexibility of the sheet, based on the method for measuring the compressibility described in JIS L1096-8.20 (2010), three test pieces of 3 cm × 3 cm were stacked and measured at 50 gf / cm 2 Place it under the standard pressure for 1 minute, measure the thickness (T0: mm), then, at 300gf / cm 2 It was left under pressure for 1 minute, and the thickness (T1: mm) was measured. Using the thickness measured by the above-mentioned measuring method, the compressibility (Cr: %) was calculated using the following mathematical formula.

[0218] · Cr=(T0-T1) / T0×100.

[0219] B. Compressive modulus of elasticity

manufacture example 1

[0244] [Production Example 1] [Preparation of polyester polyol (a) having carbonate group and oxycarbonyl group as ester group]

[0245] Into a reaction container equipped with a stirrer and a heating device, 500 parts by mass of a polycarbonate diol with an Mn of 2,000 ["ETERNACOLL UH-200" manufactured by Ube Industries, Ltd.], 500 parts by mass of a polycarbonate diol with an Mn of 2,000 Polycaprolactone diol ["PLACCEL 220" manufactured by Daicel Corporation] and 0.1 parts by mass of dibutyltin oxide as a catalyst were heated to a temperature of 220°C under a nitrogen atmosphere, and a transesterification reaction was carried out for 10 hours to obtain Mn 2,000 polyester polyol (a) having a carbonate group and an oxycarbonyl group as an ester group.

manufacture example 2

[0246] [Production Example 2] [Preparation of polyester polyol (b) having carbonate group and oxycarbonyl group as ester group]

[0247] The amount of polycarbonate diol with Mn of 2,000 ["ETERNACOLL UH-200" manufactured by Ube Industries, Ltd.] was changed to 600 parts by mass, and the amount of polycaprolactone diol with Mn of 2,000 ["ETERNACOLL UH-200" manufactured by Daicel Corporation] was changed to 600 parts by mass. Except having changed the addition amount of PLACCEL 220"] into 400 mass parts, it carried out similarly to manufacture example 1, and obtained the polyester polyol (b) which has a carbonate group and an oxycarbonyl group as an ester group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com