Knife embryo processing device and process thereof

A processing technology and processing device technology, applied in the direction of anodic oxidation, etc., can solve the problems of lack of surface treatment process, complicated processing technology, and low service life of knife blanks, and achieve the advantages of reducing adjustment and transportation problems, simple operation, and fast production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

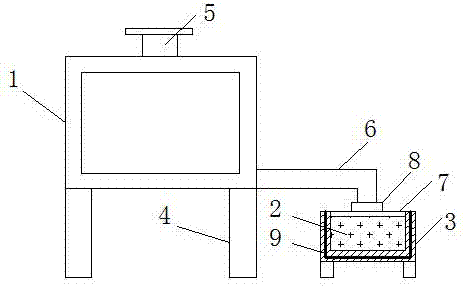

[0029] Such as figure 1 A knife blank processing device shown includes an injection molding machine body 1 and a knife mold 2, the knife mold 2 is located in a cavity 3, and legs 4 are provided at the bottom of the injection molding machine body 1 and the cavity 3 , the top of the injection molding machine body 1 is connected with a feed pipe 5, the injection molding machine body 1 and the die 2 are connected by an injection pipe 6, and an injection head 8 is arranged between the die die 2 and the injection pipe 6 , the mold cavity 3 is provided with a heating resistance wire 9, and the top of the knife mold 2 is provided with a mold cover 7.

[0030] The present invention also provides a kind of processing technique of knife embryo, and concrete steps are as follows:

[0031] S1: Preparation of raw materials, use scrap iron and scrap steel raw materials, buy scrap iron and scrap steel in the market, and reserve;

[0032] S2: Raw material pretreatment, the raw material obtai...

Embodiment 2

[0041] Such as figure 1 A knife blank processing device shown, a knife blank processing device, includes an injection molding machine body 1 and a knife mold 2, the knife mold 2 is located in the mold cavity 3, and the injection molding machine body 1 and the mold cavity 3 The bottom is provided with supporting legs 4, the top of the injection molding machine body 1 is connected with a feed pipe 5, the injection molding machine body 1 and the knife mold 2 are connected by an injection pipe 6, and the knife mold 2 and the injection pipe 6 An injection molding head 8 is arranged between them, a heating resistance wire 9 is arranged inside the mold cavity 3 , and a mold cover 7 is arranged on the top of the knife mold 2 .

[0042] The present invention also provides a kind of processing technique of knife embryo, and concrete steps are as follows:

[0043] S1: Preparation of raw materials, use scrap iron and scrap steel raw materials, buy scrap iron and scrap steel in the market...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com