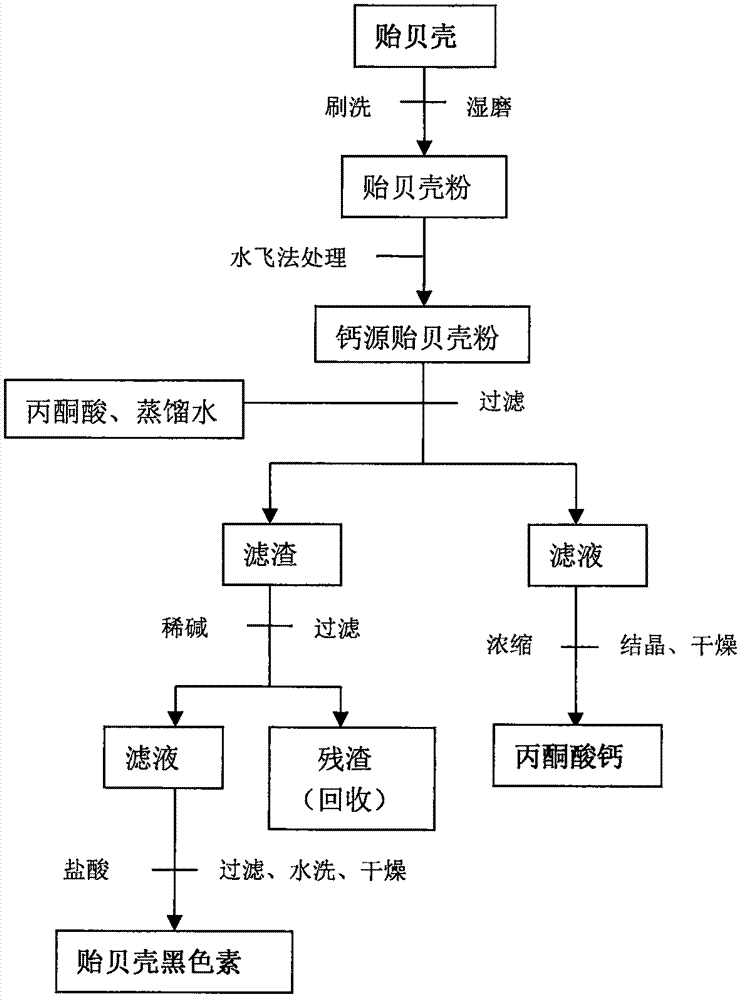

Method for synthesizing calcium pyruvate based on mussel shell melanin separation

A technology of calcium pyruvate and mussel shells, applied in chemical instruments and methods, preparation of organic compounds, drug combinations, etc., can solve the problems of high prices and achieve significant inhibitory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0015] Example: Wash 110kg of mussel shells and put them into a wet pulverizer for grinding (below 60 mesh), and process them with the water-flying method to obtain calcium source mussel shell powder (about 100kg in dry weight). Add 82kg of 98% pyruvic acid and 20kg of distilled water, stir, and filter after insulated at 60°C for 3 hours. (1) Wash the filter residue with tap water to neutrality, dissolve it with 30 liters of 0.5M sodium hydroxide and filter (filter residue recovery), Add 5 liters of 4M hydrochloric acid to the filtrate and then filter. The filter residue is washed with water to remove salt, deacidify (to neutral), and dry to obtain 390 g of mussel shell melanin; Dry at ~120°C to get calcium pyruvate [C 6 h 6 CaO 6 ] 97kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com