Resin composition, laminated board, prepreg and preparation method and application of prepreg

A technology of resin composition and prepreg, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of low bond strength and impact resistance strength, achieve strong adhesion, improve bond strength, Effect of Strong Peel Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

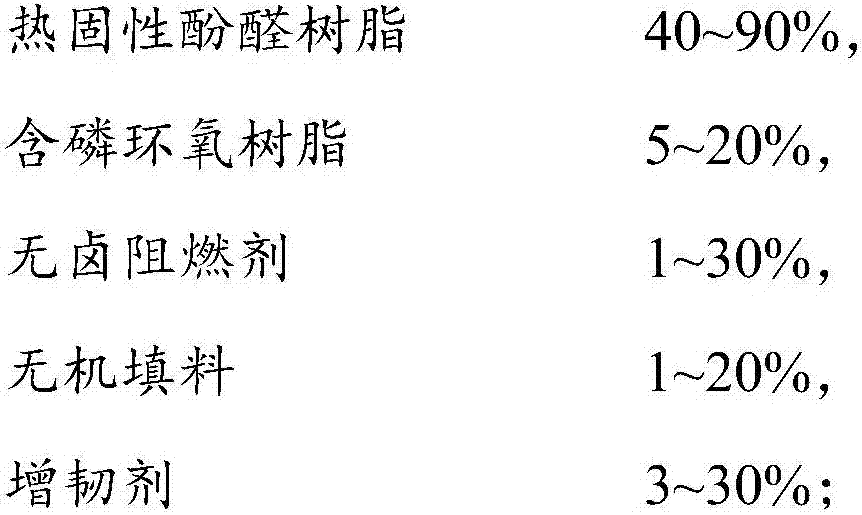

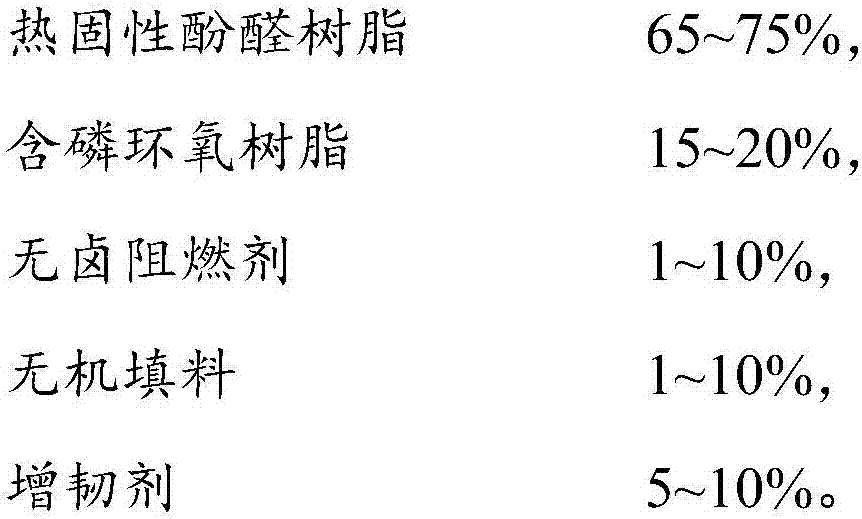

Method used

Image

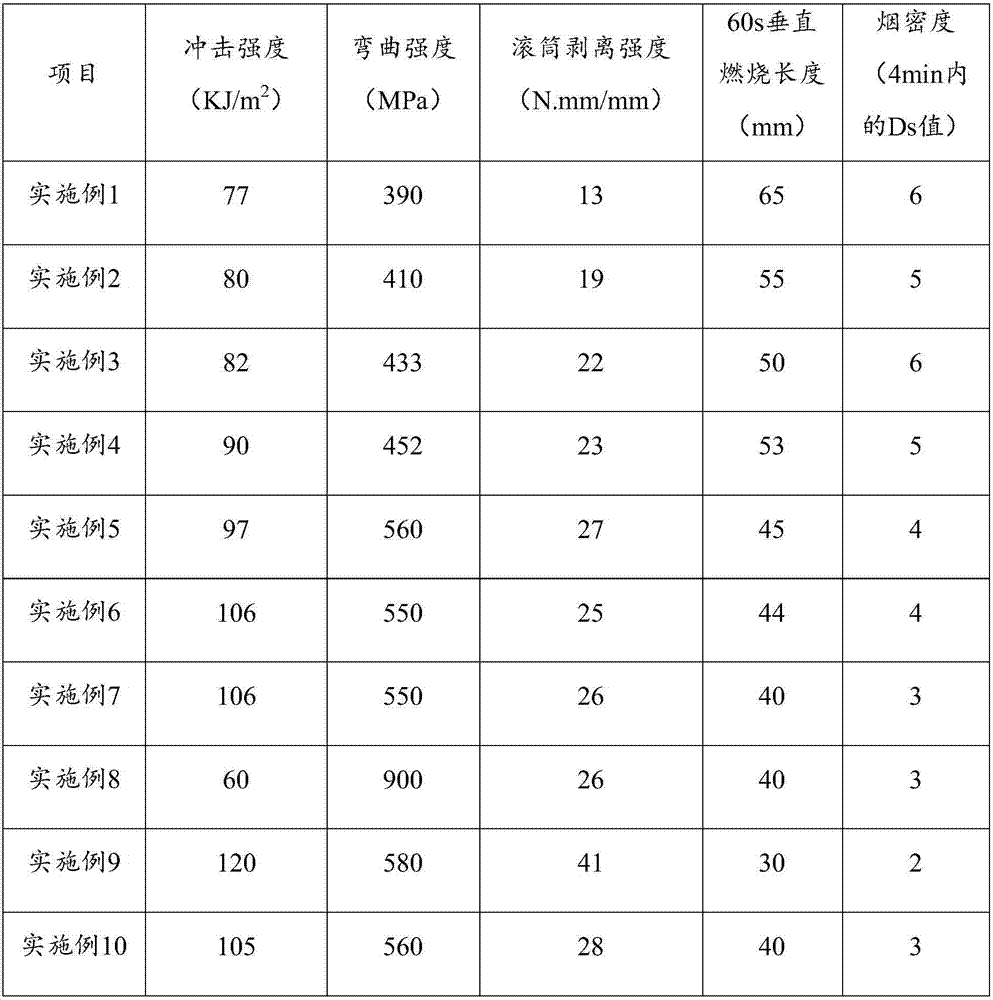

Examples

Embodiment 1

[0053] Add 80kg of PF5220, 5kg of SQEB-801EK75, 5kg of polyvinyl alcohol, 5kg of ammonium polyphosphate, and 5kg of aluminum hydroxide into the reaction kettle, stir at high speed for 120min, and obtain a prepreg glue with a density of 1.1g / m 3 ; Pour the prepreg glue into the dipping tank of the gluing machine, pre-soak and main dip through the gluing machine, evenly coat the resin glue on the continuous fabric, the continuous fabric is 300g glass fiber satin cloth, impregnate The glass fiber cloth is baked in an oven at 110-140°C, and the production speed is 2m / min. During this process, the resin content is controlled to be 45±3%. After the production is completed, it is rolled up and covered with a layer of PE grid film on both sides; into composites. Peel off the PE grid film of the produced composite parts, cut them into 30×30cm size, stack 8 pieces together, and press them with a hot press. The pressing temperature is 140°C, the time is 1h, and the pressure is from 0.5Mp...

Embodiment 2

[0055] Add 70kg of PF5220, 10kg of SQEB-801EK75, 5kg of polyvinyl alcohol, 10kg of ammonium polyphosphate, 5kg of aluminum hydroxide, and an appropriate amount of methanol into the reactor, and stir at high speed for 120 minutes to obtain a prepreg glue with a density of 1.1g / m 3 ; Pour the prepreg glue into the dipping tank of the gluing machine, pre-soak and main dip through the gluing machine, evenly coat the resin glue on the continuous fabric, the continuous fabric is 300g glass fiber satin cloth, impregnate The glass fiber cloth is baked in an oven at 110-140°C, and the production speed is 2m / min. During this process, the resin content is controlled to be 45±3%. After the production is completed, it is rolled up and covered with a layer of PE grid film on both sides; into composites. Other strength tests are the same as in Example 1.

Embodiment 3

[0057] Add 60kg of PF5220, 15kg of SQEB-801EK75, 5kg of polyvinyl alcohol, 10kg of ammonium polyphosphate, 10kg of aluminum hydroxide, and an appropriate amount of methanol into the reaction kettle, stir at high speed for 120min, and obtain a prepreg glue with a density of 1.1g / m 3 ; Pour the prepreg glue into the dipping tank of the gluing machine, pre-soak and main dip through the gluing machine, evenly coat the resin glue on the continuous fabric, the continuous fabric is 300g glass fiber satin cloth, impregnate The glass fiber cloth is baked in an oven at 110-140°C, and the production speed is 2m / min. During this process, the resin content is controlled to be 45±3%. After the production is completed, it is rolled up and covered with a layer of PE grid film on both sides; into composites. Other strength tests are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com