Normal-temperature type thermoset epoxy asphalt material for highway long steep slope section asphalt pavement as well as preparation method and application of normal-temperature type thermoset epoxy asphalt material

An epoxy asphalt material, highway technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as rutting disease, achieve the effects of reducing traffic congestion, moderate price, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

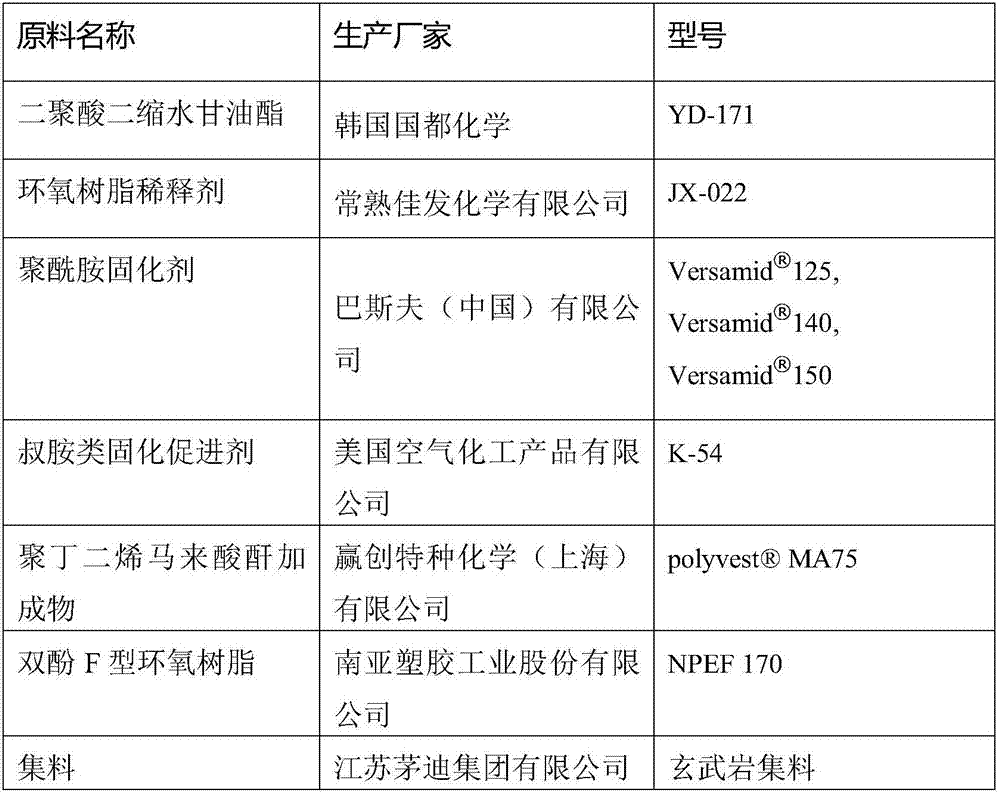

Method used

Image

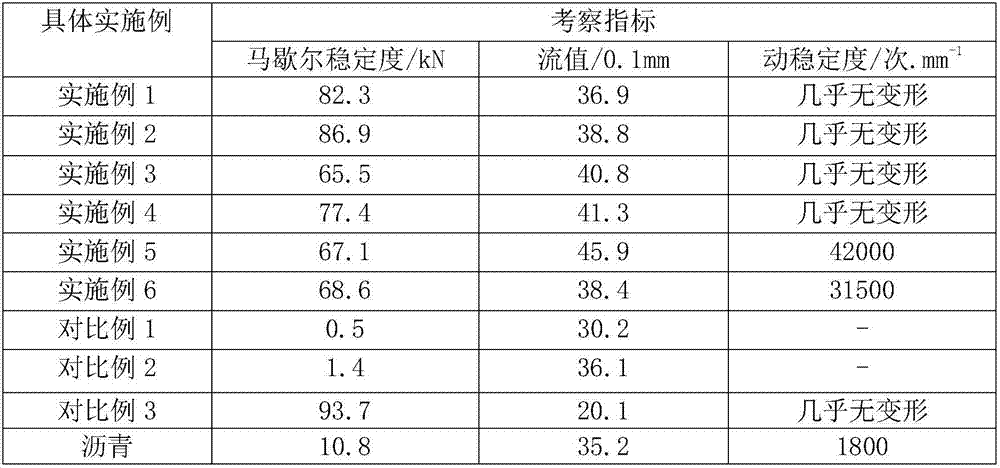

Examples

Embodiment 1

[0026] The normal temperature type thermosetting epoxy asphalt material of the present invention is made up of A component, B component and C component, according to the actual needs of the asphalt upper layer, determine to use AC- 13 gradation median line gradation; then, after normal temperature type thermosetting epoxy asphalt of the present invention and AC-13 gradation are mixed evenly, operations such as carrying out the transportation, paving, rolling of this modified asphalt mixture, That is, the preparation of the normal temperature thermosetting epoxy asphalt material of the present invention is completed.

[0027] (1) Preparation of component A

[0028] First, the dimer acid glycidyl ester of 8 mass parts and the epoxy resin diluent of 17 mass parts are heated to 80 ℃, simultaneously, the matrix asphalt of 50 mass parts is heated to 130 ℃; Then, the matrix asphalt (AH- 70) Keep stirring at 90° C. for 30 minutes in a stirrer at 800 RPM with dimer acid glycidyl ester...

Embodiment 2

[0038] The normal temperature type thermosetting epoxy asphalt material of the present invention is made up of A component, B component and C component, according to the actual needs of the asphalt upper layer, determine to use AC- 16 gradation median line gradation; then, after normal temperature type thermosetting epoxy asphalt of the present invention and AC-16 gradation are mixed evenly, operations such as carrying out the transportation, paving, rolling of this modified asphalt mixture, That is, the preparation of the normal temperature thermosetting epoxy asphalt material of the present invention is completed.

[0039] (1) Preparation of component A

[0040] First, heat 12 parts by mass of glycidyl dimer acid and 26 parts by mass of epoxy resin diluent (neopentyl glycol glycidyl ether) to 80°C, and at the same time, heat 38 parts by mass of base pitch to 125°C ; Then, the base asphalt (AH-70) and dimer acid glycidyl ester, epoxy diluent were kept at 125 °C for 30 minutes ...

Embodiment 3

[0050] The normal temperature type thermosetting epoxy asphalt material of the present invention is made up of A component, B component and C component, according to the actual needs of the asphalt upper layer, determine to use AC- 13 gradation median line gradation; then, after normal temperature type thermosetting epoxy asphalt of the present invention and AC-13 gradation are mixed evenly, operations such as carrying out the transportation, paving, rolling of this modified asphalt mixture, That is, the preparation of the normal temperature thermosetting epoxy asphalt material of the present invention is completed.

[0051] (1) Preparation of component A

[0052] First, heat 5 parts by mass of dimer acid glycidyl ester and 15 parts by mass of epoxy resin diluent to 70°C respectively, and heat 100 parts by mass of base asphalt to 130°C; then, mix base asphalt with dimer acid Glycidyl ester and epoxy diluent were kept stirring at 125° C. for 35 minutes in a stirrer at 800 RPM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com