Fatty acid type diesel oil anti-wear agent and preparation method thereof

A fatty acid and antiwear agent technology, which is applied in the field of fatty acid diesel antiwear agent and its preparation, can solve the problems of high production environment and operation requirements, heavy labor, low production efficiency, etc. The effect of high strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

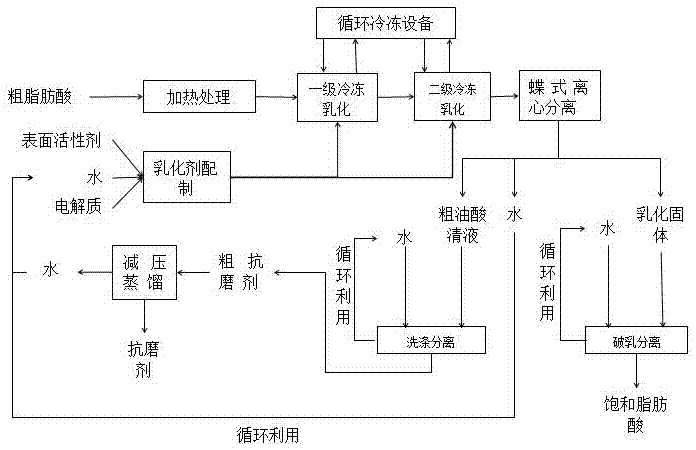

[0027] The preparation method of the fatty acid type diesel antiwear agent of the present invention includes the following steps:

[0028] Step 1: After being emulsified by an emulsifier, the crude fatty acid is divided into crude fatty acid clear liquid, emulsified solid and water by a butterfly separator; the crude fatty acid is obtained by preheating to completely dissolve the solid in it and then slowly cooling and crystallization.

[0029] The emulsified mixture is separated by a butterfly centrifuge, which can efficiently divide the mixture into three phases. After separation, the mixture is divided into crude fatty acid clear liquid, emulsified solids and water. The feeding and discharging of the butterfly centrifuge are continuous operation, and the operation is remote automatic control.

[0030] Step 2: The crude fatty acid clear liquid is washed with hot water and separated from the oil and water, and then the water content is reduced to less than 0.03% by thin film distill...

Embodiment 1

[0037] The preparation method of fatty acid type diesel antiwear agent includes the following steps:

[0038] Step 1: After being emulsified by an emulsifier, the crude fatty acid is divided into crude fatty acid clear liquid, emulsified solid and water by a butterfly separator; the crude fatty acid is obtained by preheating to completely dissolve the solid in it and then slowly cooling and crystallization.

[0039] The emulsified mixture is separated by a butterfly centrifuge, which can efficiently divide the mixture into three phases. After separation, the mixture is divided into crude fatty acid clear liquid, emulsified solids and water. The feeding and discharging of the butterfly centrifuge are continuous operation, and the operation is remote automatic control.

[0040] Step 2: The crude fatty acid clear liquid is washed with hot water and separated from the oil and water, and then the water content is reduced to less than 0.03% by thin film distillation to obtain the fatty aci...

Embodiment 2

[0046] The preparation method of fatty acid type diesel antiwear agent includes the following steps:

[0047] Step 1: After being emulsified by an emulsifier, the crude fatty acid is divided into crude fatty acid clear liquid, emulsified solid and water by a butterfly separator; the crude fatty acid is obtained by preheating to completely dissolve the solid in it and then slowly cooling and crystallization.

[0048] The emulsified mixture is separated by a butterfly centrifuge, which can efficiently divide the mixture into three phases. After separation, the mixture is divided into crude fatty acid clear liquid, emulsified solids and water. The feeding and discharging of the butterfly centrifuge are continuous operation, and the operation is remote automatic control.

[0049] Step 2: The crude fatty acid clear liquid is washed with hot water and separated from the oil and water, and then the water content is reduced to less than 0.03% by thin film distillation to obtain the fatty aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com