A construction method of foam concrete roof thermal insulation and waterproof integrated system

A technology of foam concrete and construction method, which is applied to roofs, roof coverings, and roofs using sealed aggregates, etc., and can solve problems such as poor surface flatness of waterproof membranes, detachment of waterproof membranes from base materials, and long construction periods. , to achieve the effect of good thermal insulation performance, low cost and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the present invention more comprehensible, a preferred embodiment is now described in detail with accompanying drawings as follows.

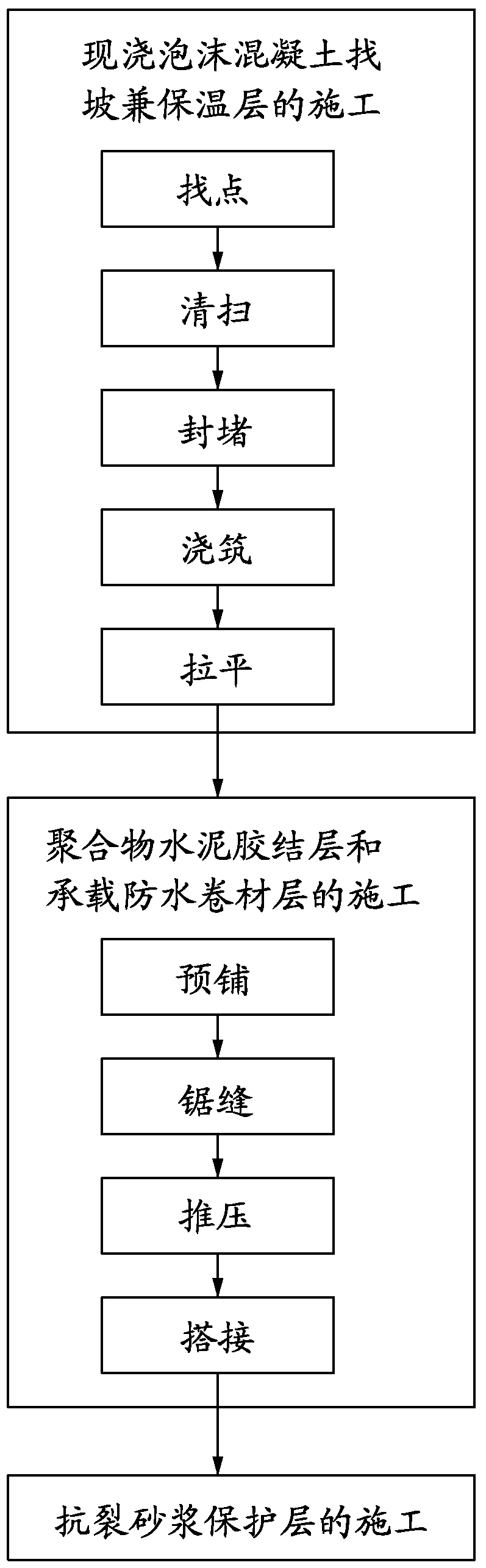

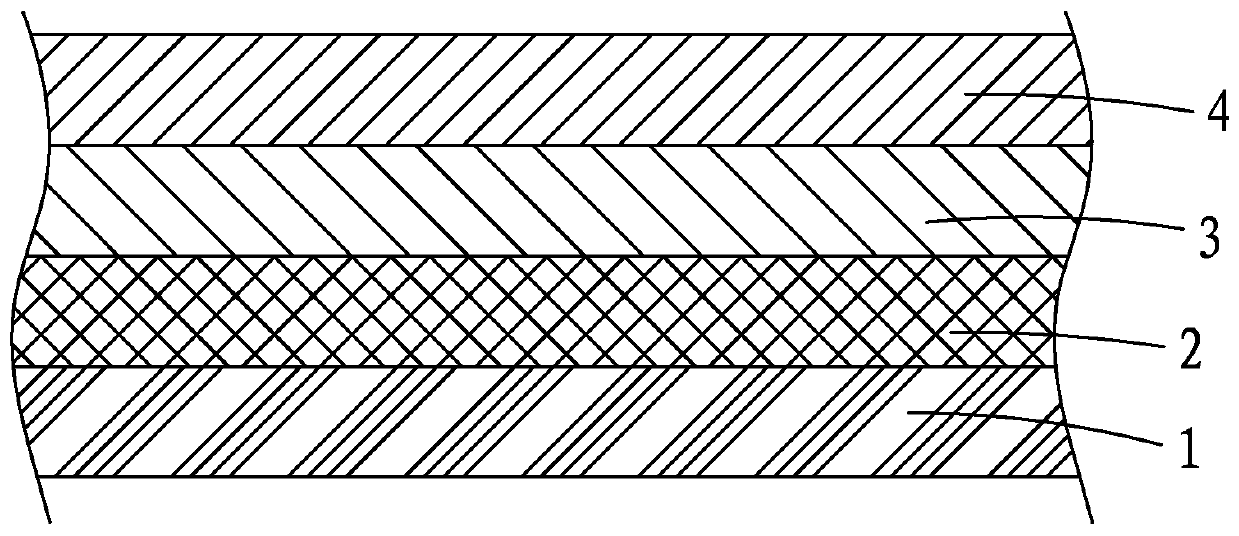

[0037] Such as figure 1 and figure 2 As shown, a construction method of a foam concrete roof thermal insulation and waterproof integrated system of the present invention, the foam concrete roof thermal insulation and waterproof integrated system includes cast-in-place foam concrete slope finding and thermal insulation layer 1, polymerization Material cement bonding layer 2, bearing waterproof coiled material layer 3 and anti-cracking mortar protective layer 4, its construction method specifically includes the following steps:

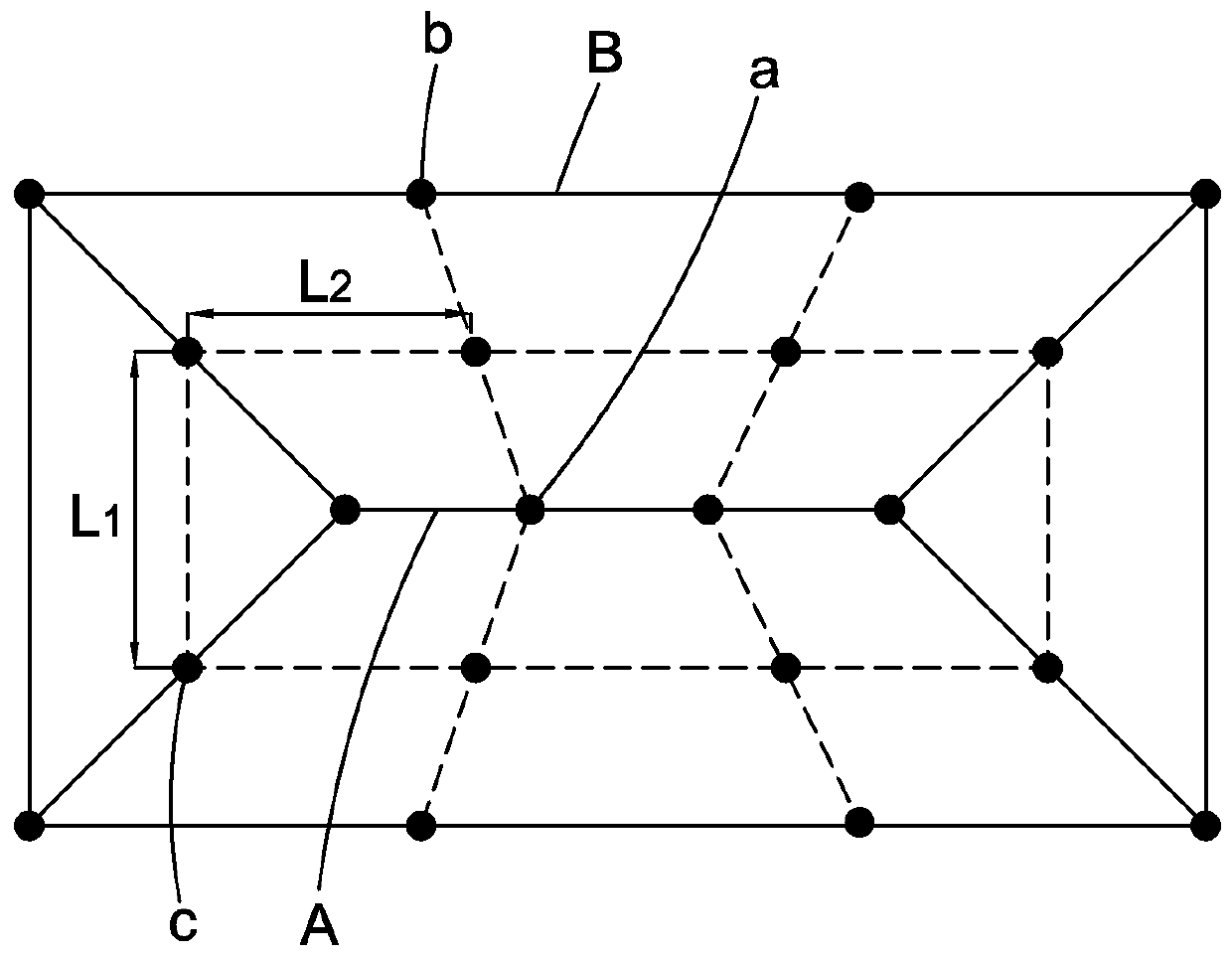

[0038] Step 1. Foam concrete is poured according to the slope, average thickness and various energy-saving technical indicators required by the design, and the construction of the slope-finding and insulation layer 1 of the cast-in-place foam concrete is completed. The slope-finding and insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com