Waste material utilizing device used in primary screening of biomass pellet fuel

A technology of biomass particles and fuel, which is applied in fuel supply, block/powder fuel preparation, filtering and sieving, etc. It can solve problems such as difficult molding, increased production cost, breakdown, etc., and achieves easy to use and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

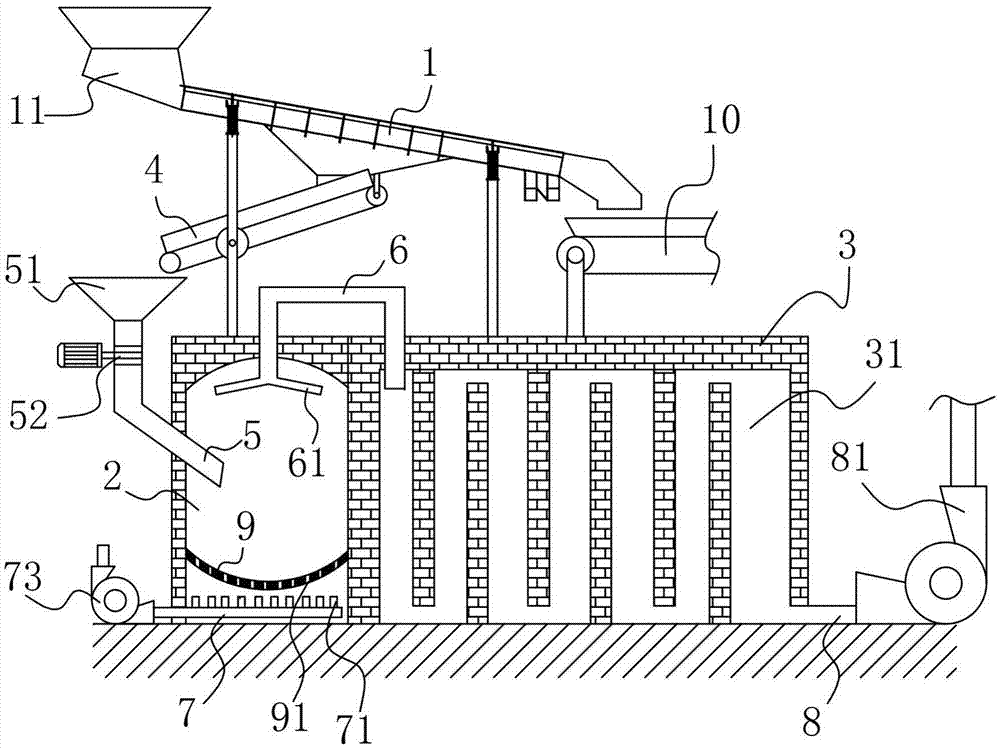

[0012] Such as figure 1 As shown, the waste utilization device in the primary screening of biomass pellet fuel includes a connected vibrating screen 1, a feed inlet 11 is provided at the upper end of the vibrating screen 1, a conveying device 4 is provided below the vibrating screen 1, and a combustion chamber is also included. 2 and dust removal chamber 3, combustion chamber 2 and dust removal chamber 3 can be two independent rooms covered by brick-concrete structure, the discharge end of vibrating screen 1 can be connected to the feed port of the pulverizer or on the conveyor belt 10, In order to save space, the vibrating screen 1 and the conveyor belt 10 or the pulverizer can be installed on the combustion chamber 2 and the dust removal chamber 3. The combustion chamber 2 communicates with the dust removal chamber 3 through the hot gas pipe 6. The feed pipe 5 is provided with a feed hopper 51 and a blower fan 52 at one end of the feed pipe 5 located outside the room. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com