Loaded Pd catalyst, and preparation method and application thereof

A supported catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low selectivity, reduce the reaction temperature, and the preparation method is simple and effective. Good for adsorption and activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0026] Example 1 1%wt Pd / LaFeO 3 Catalyst preparation

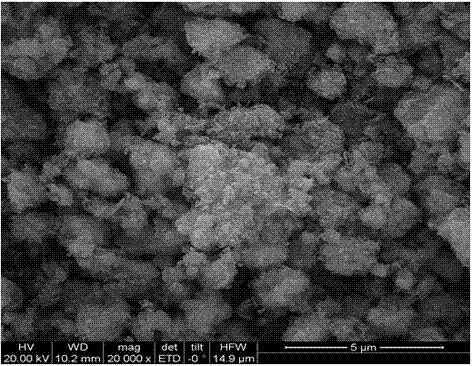

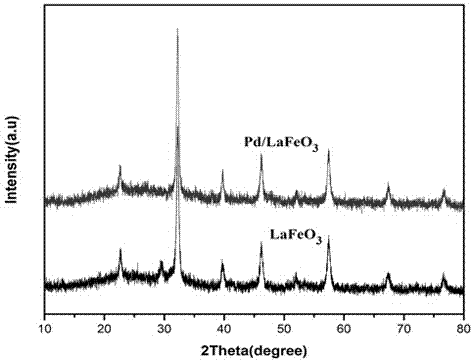

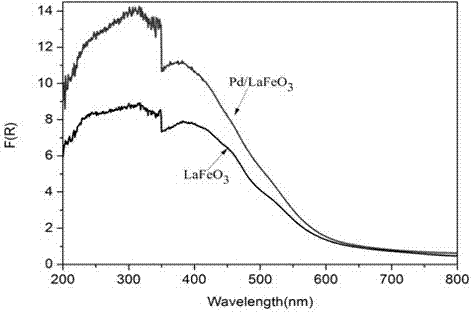

[0027] Dissolve 1.8 g of PVP in 40 mL of isopropanol, mix and stir until completely dissolved, then add 1.5 mL of nitric acid to adjust the solution to acidity, and continue stirring to add 2.02 g of Fe(NO 3 ) 3 9H 2 O and 1.6246g of La(NO 3 ) 3 ·6H 2 O, continue to stir vigorously for more than 10h until the solution becomes yellow and viscous, then transfer to an oven, fully dry at 80°C, transfer to a muffle furnace and gradually heat up to 600°C, calcined for 2h, to obtain LaFeO 3 solid powder.

[0028] Weigh 1.0g LaFeO 3 Solid powder, add 8 mL of PdCl at a concentration of 1.2 mg / mL 2 solution, and introduced 100mL deionized water, stirred for 30min, ultrasonicated for 15min, adjusted the pH value of the solution to about 10, and then slowly added NaBH with a concentration of 0.1mol / L 4 Mix the solution with NaOH to excess, so that Pd is completely reduced, centrifuge, wash with deionized water until the ion ...

Embodiment 22

[0032] Example 2 2%wt Pd / LaFeO 3 Catalyst preparation

[0033] Dissolve 1.8 g of PVP in 40 mL of isopropanol, mix and stir until completely dissolved, then add 1.5 mL of nitric acid to adjust the solution to acidity, and continue stirring to add 2.02 g of Fe(NO 3 ) 3 9H 2 O and 1.6246g of La(NO 3 ) 3 ·6H 2 O, continue to stir vigorously for more than 10h until the solution becomes yellow and viscous, then transfer to an oven, fully dry at 80°C, then transfer to a muffle furnace and gradually heat up to 600°C, calcined for 2h, to obtain LaFeO 3 solid powder.

[0034] Weigh 1.0g LaFeO 3 Solid powder, add 16 mL of PdCl at a concentration of 1.2 mg / mL 2 solution, and introduced 200mL deionized water, stirred for 30min, ultrasonicated for 15min, adjusted the pH value of the solution to about 10, and then slowly added NaBH with a concentration of 0.1mol / L 4 Mix the solution with NaOH to an excess to completely reduce Pd, centrifuge, wash with deionized water until the ion c...

Embodiment 3

[0035] The performance evaluation of embodiment 3 catalyst

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com