A tool system for ultra-high-speed cutting of CNC machine tools

A technology of CNC machine tool and cutting tool system, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the problem of inability to meet the requirements of ultra-high speed cutting speed, low moving speed of machine tool spindle feed system, and low speed of CNC machine tool spindle and other issues, to achieve great social and economic benefits, good processing effect, and fill the technical gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

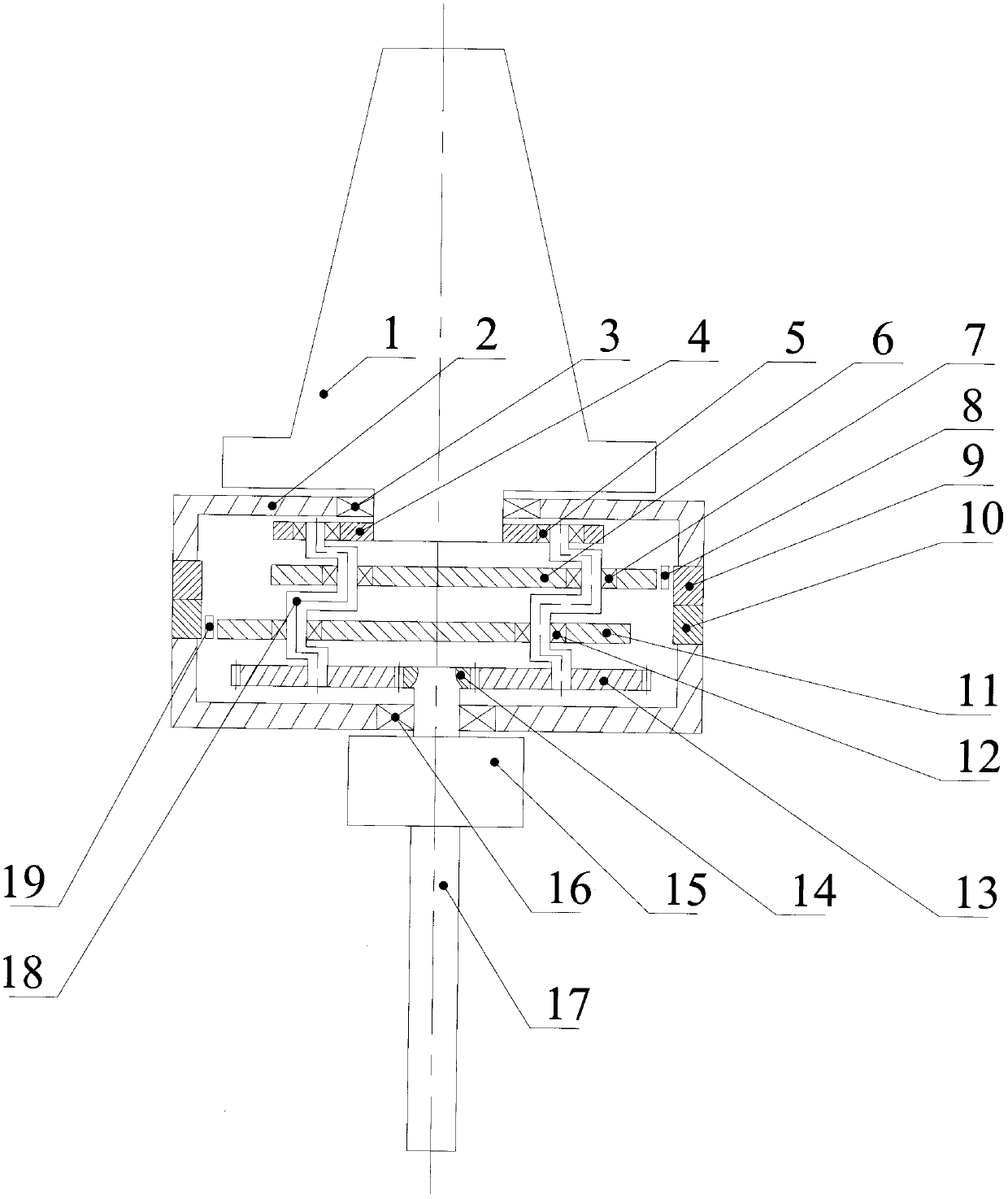

[0018] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with figure 1 , figure 2 The present invention will be specifically described. The upper end of the main shaft 1 is installed on the existing CNC machine tool. The machine tool transmits the existing rotational speed to the main shaft 1 to drive the main shaft 1 to rotate. At this time, the rotational speed of the main shaft 1 is relatively low. On the housing 2, the main shaft 1 is connected with the turret 4, and the main shaft 1 drives the turret 4 to rotate synchronously. Revolution, crankshaft 18 is an eccentric shaft, and the middle part of crankshaft 18 is equipped with epicycloid wheel A 6, cycloid wheel bearing A 7), epicycloid wheel B 11 and cycloid wheel bearing B 12, crankshaft 18 drives epicycloid wheel A 6 and the epicycloid wheel B 11 rotate, and the hypocycloid wheel A 9 and the hypocycloid wheel B 10 matched with the epicycloid wheel A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com