Method for preparing Cu-Sn-Bi bearing alloy by discharge plasma assisted ball-milling

A technology of discharge plasma and bearing alloy, which is applied in the field of preparation of Cu-based sliding bearing materials, can solve problems such as difficult guarantees, achieve high load-carrying capacity, realize strength and plasticity, and improve the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

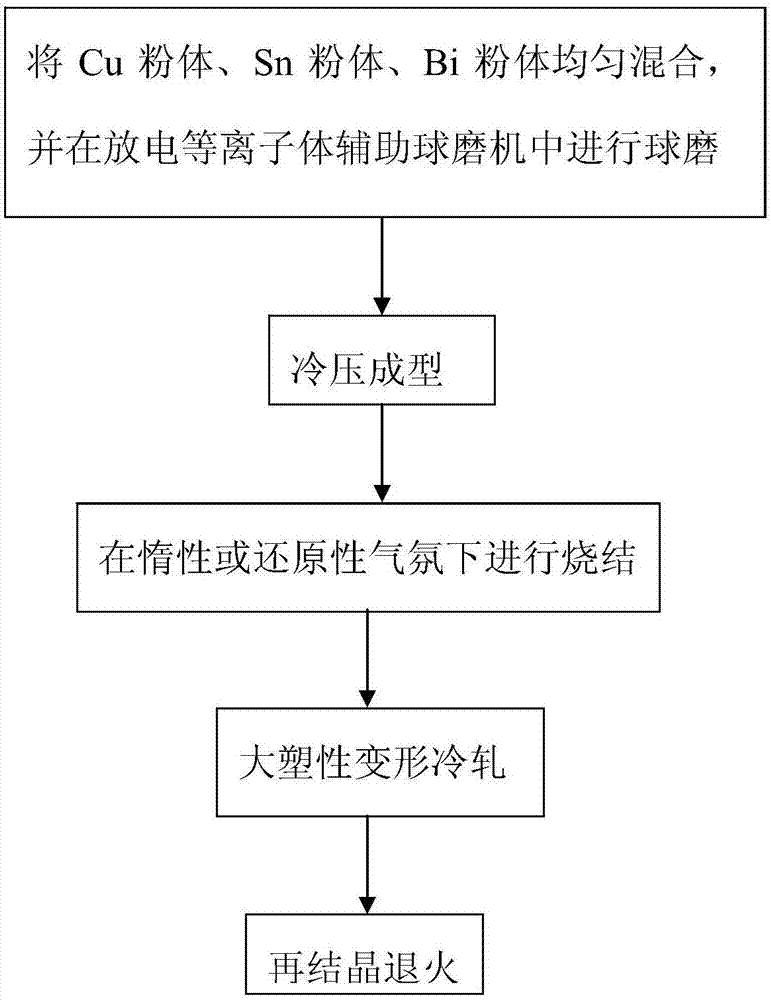

[0036] Such as figure 1 As shown, the steps of the method for preparing Cu-Sn-Bi bearing alloys by discharge plasma assisted ball milling in this embodiment are as follows:

[0037] Cu powder with a particle size of 10 to 60 μm and a purity of 99.9%, Sn powder with a particle size of 10 to 50 μm and a purity of 99.5%, Bi with a particle size of 10 to 50 μm and a purity of 99.99% were calculated as Cu-10% Sn -3%Bi mass percentage is simply and uniformly mixed, and the mixed powder is refined and activated by using a discharge plasma assisted ball mill under the protection of argon to obtain a Cu-10%Sn-3%Bi supersaturated solid solution alloy with a sheet structure powder. The adopted rotating speed is 960rpm, the discharge current is 1.5A, the ball-material ratio is 30:1, and the ball milling time is 5h. The powder is in the form of flakes with a size of 20 μm.

[0038] Weigh 9 g of the above-mentioned Cu-10%Sn-3%Bi supersaturated solid solution alloy powder and put it into ...

Embodiment 2

[0042] The procedure of this embodiment is basically the same as that of Embodiment 1, except that the recrystallization annealing temperature selected for the cold-rolled sample is 700°C.

Embodiment 3

[0044] The steps of this embodiment are basically the same as those of Embodiment 1, except that the recrystallization annealing temperature selected for the cold-rolled sample is 750°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com