Hydrogenation reaction device and hydrogenation reaction method for producing hydrogen peroxide through fluidized bed

A technology for the production of hydrogen peroxide and hydrogenation reaction, applied in the fields of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc. Problems such as high cost and large floor area, to achieve the effect of maintaining catalyst concentration, improving hydrogenation efficiency, and ensuring filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

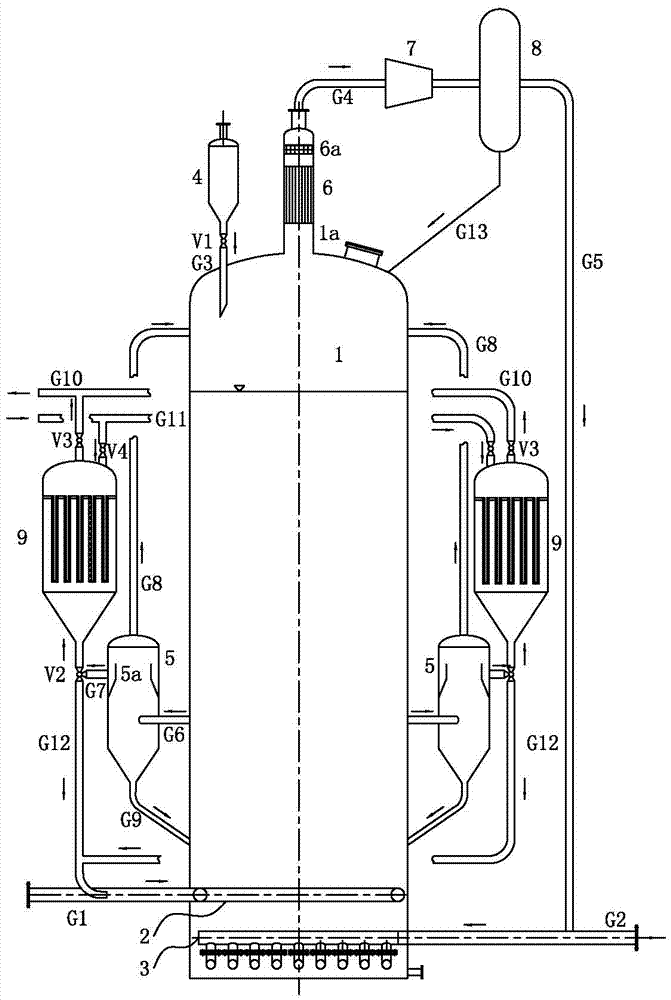

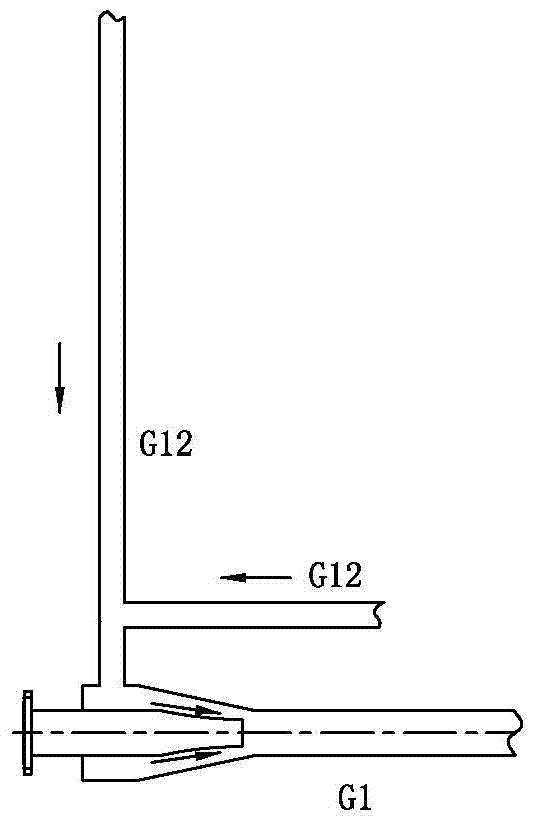

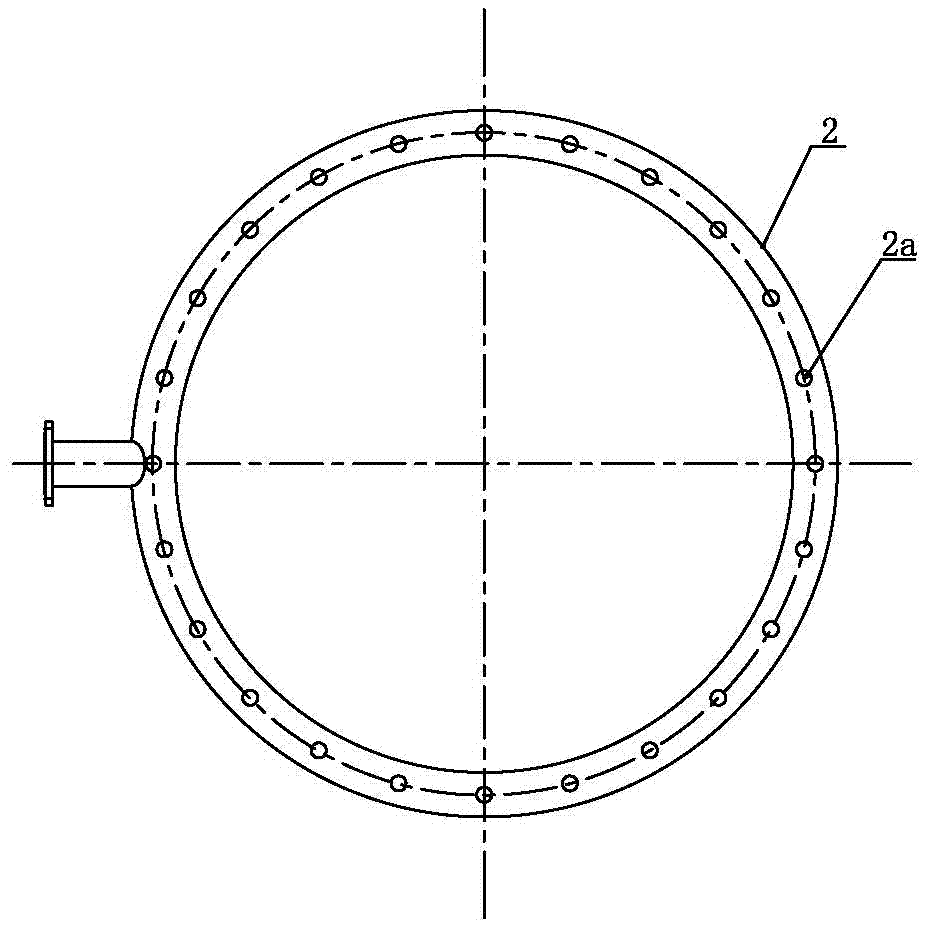

[0029] Such as figure 1 As shown, the hydrogenation reaction device for producing hydrogen peroxide in a fluidized bed of the present invention includes a vertical hydrogenation reactor 1, the bottom of the hydrogenation reactor 1 is provided with a hydrogenation reactor working fluid distribution pipe 2, and the hydrogenation reactor working fluid distribution pipe 2 The inlet is connected to the inlet pipe G1 of the working fluid of the hydrogenation kettle, and a hydrogen distribution device 3 is provided under the distribution pipe 2 of the working fluid of the hydrogenation kettle. Catalyst addition pipe G3, the upper end of catalyst addition pipe G3 is connected with the outlet of catalyst addition tank 4 through catalyst addition valve V1; There are at least two reactor outlets.

[0030] Open the catalyst addition valve V1 to put an appropriate amount of catalyst into the hydrogenation reactor 1. At the same time, the fresh working fluid is distributed through the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com