Application of CaO/AC solid catalyst in catalysis of acetic acid in ozone oxidation wastewater

A solid catalyst and ozone oxidation technology, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of low catalyst consumption, mild use conditions and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1CaO / AC solid catalyst

[0027] Add 4g of activated carbon into 10mL of calcium nitrate solution with a mass fraction of 15%, shake and impregnate for 2h, vacuum-dry the impregnated material at 110°C, place it in a tube furnace, and calcinate it at 550°C for 4h under a nitrogen atmosphere to obtain CaO / AC solid catalyst.

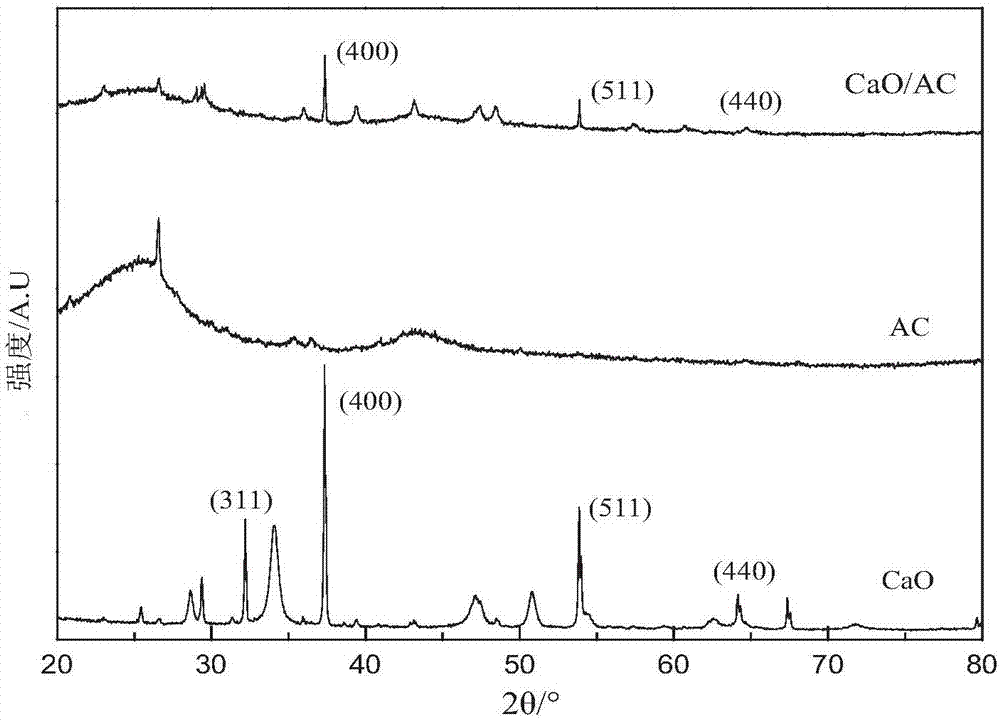

[0028] The X-ray diffraction pattern of the prepared CaO / AC solid catalyst is as follows figure 2 shown by figure 2 It can be seen that CaO is loaded on the AC support.

Embodiment 2

[0029] The preparation of embodiment 2CaO / AC solid catalyst

[0030] Add 4g of activated carbon into 10mL of calcium nitrate solution with a mass fraction of 20%, oscillate and impregnate for 2h, dry the impregnated product in vacuum at 110°C, place it in a tube furnace, and calcinate at 600°C for 4h under a nitrogen atmosphere to obtain CaO / AC solid catalyst.

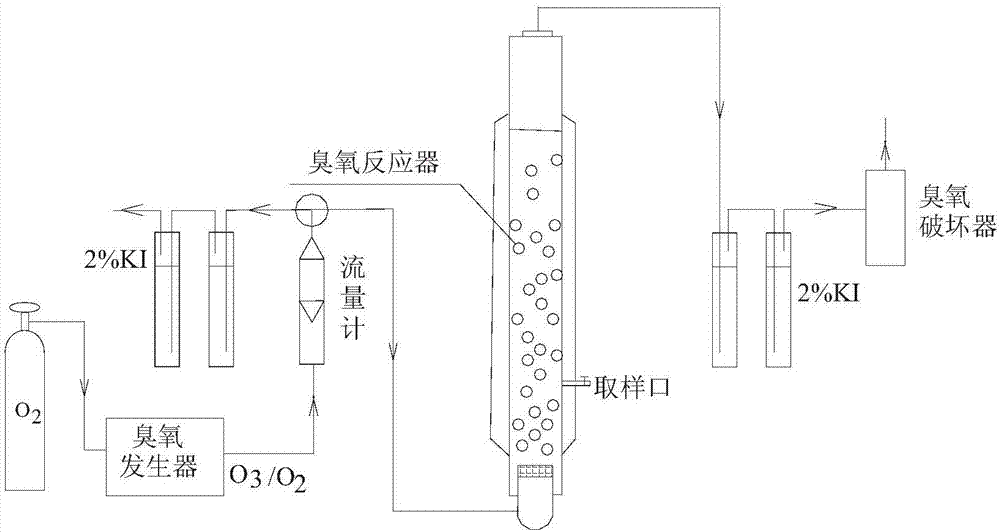

[0031] In the following examples, the CaO / AC solid catalyst prepared in Example 1 was used to catalyze ozonation to degrade acetic acid simulated wastewater. The concentration of acetic acid in the acetic acid simulated wastewater was 200 mg / L, and the volume of acetic acid simulated wastewater treated each time was 500 mL. The reaction apparatus used is as figure 1 shown.

[0032] Acetic acid simulates the pH of wastewater using NaOH solution and HNO 3 The solution is adjusted.

[0033] Ozone was continuously introduced into the simulated acetic acid wastewater in the form of ozone-containing air.

[0034] The d...

Embodiment 3~6

[0035] Embodiment 3~6CaO / AC solid catalyst catalyzes ozone oxidation acetic acid

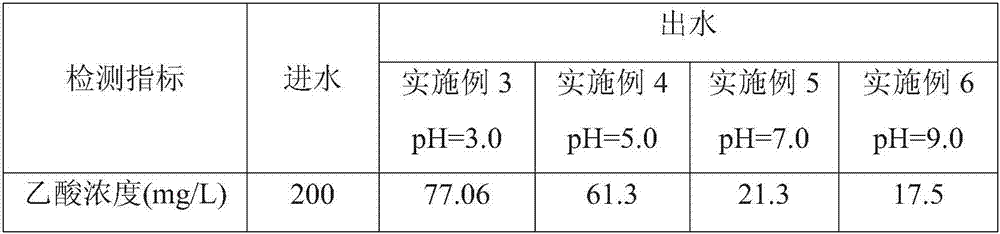

[0036] Adjust the pH of the acetic acid simulated wastewater to 3.0, 5.0, 7.0 and 9.0 respectively, and add the CaO / AC solid catalyst prepared in Example 1 to the acetic acid simulated wastewater. Based on the volume of the acetic acid simulated wastewater, the dosage of the catalyst is 6g / L, the dosage of ozone was 59.03mg / L, after 60 minutes of reaction, samples were taken to detect the concentration of acetic acid in the simulated acetic acid wastewater. The results are shown in Table 1.

[0037] Table 1

[0038]

[0039]It can be seen from Table 1 that the pH of acetic acid simulated wastewater has an important influence on the degradation effect of acetic acid. When the pH is 7 or 9, the degradation effect of acetic acid is remarkable. When the pH is 7, the removal rate of acetic acid reaches 89.4%. When it is 9, the removal rate of acetic acid reaches 91.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com