Rhodium catalyst for preparing D,L-menthol and preparation method of D,L-menthol

A rhodium catalyst and menthol technology, which is applied in the field of d,l-menthol preparation, can solve the problems of production environmental protection and unfavorable cost, and achieve the effect of mild catalyst use process conditions, simple preparation process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

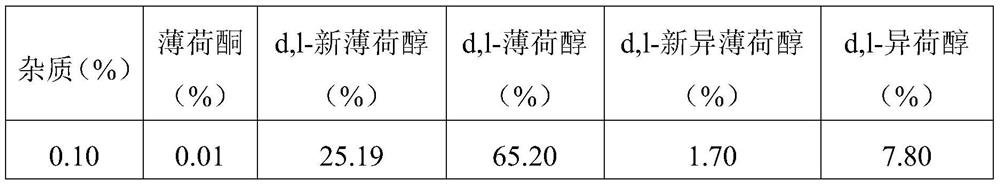

Embodiment 1

[0035] In a 250ml round bottom flask, add 15.35g rhodium trichloride trihydrate, 1.21g nickel dichloride hexahydrate and 0.63g zinc chloride, dissolve with 30ml distilled water, then add 93.4g γ-Al 2 o 3 ; Stir well, distill off the water under reduced pressure to obtain a powder; the powder is reduced in hydrogen at 250-300°C for 3-4 hours, and then the reduced product is washed with distilled water to completely remove Cl - After that, dry it again and dry it in vacuum to obtain the catalyst.

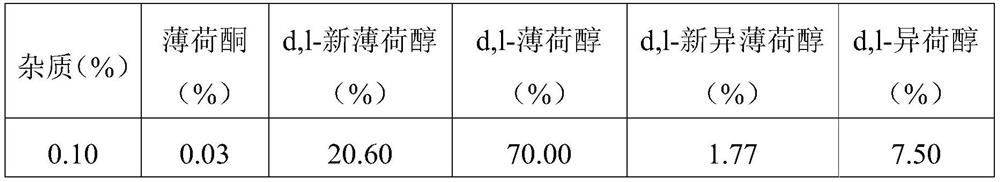

Embodiment 2

[0037] In a 250ml round bottom flask, add 20.46g rhodium trichloride trihydrate, 2.43g nickel dichloride hexahydrate and 1.25g zinc chloride, dissolve with 35ml distilled water, then add 90.8g γ-Al 2 o 3 ; Stir well, distill off the water under reduced pressure to obtain a powder; the powder is reduced in hydrogen at 250-300°C for 3-4 hours, and then the reduced product is washed with distilled water to completely remove Cl - After that, dry it again and dry it in vacuum to obtain the catalyst.

Embodiment 3

[0039]In a 250ml round bottom flask, add 25.58g rhodium trichloride trihydrate, 4.05g nickel dichloride hexahydrate and 2.08g zinc chloride, dissolve with 40ml distilled water, then add 88g γ-Al 2 o 3 ; Stir well, distill off the water under reduced pressure to obtain a powder; the powder is reduced in hydrogen at 250-300°C for 3-4 hours, and then the reduced product is washed with distilled water to completely remove Cl - After that, dry it again and dry it in vacuum to obtain the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com