Thermally driven catalyst and applications thereof

A catalyst, heat-driven technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of solar energy loss, low photocatalyst degradation efficiency, etc. Achieve the effect of wide application, repeated use of catalytic performance and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

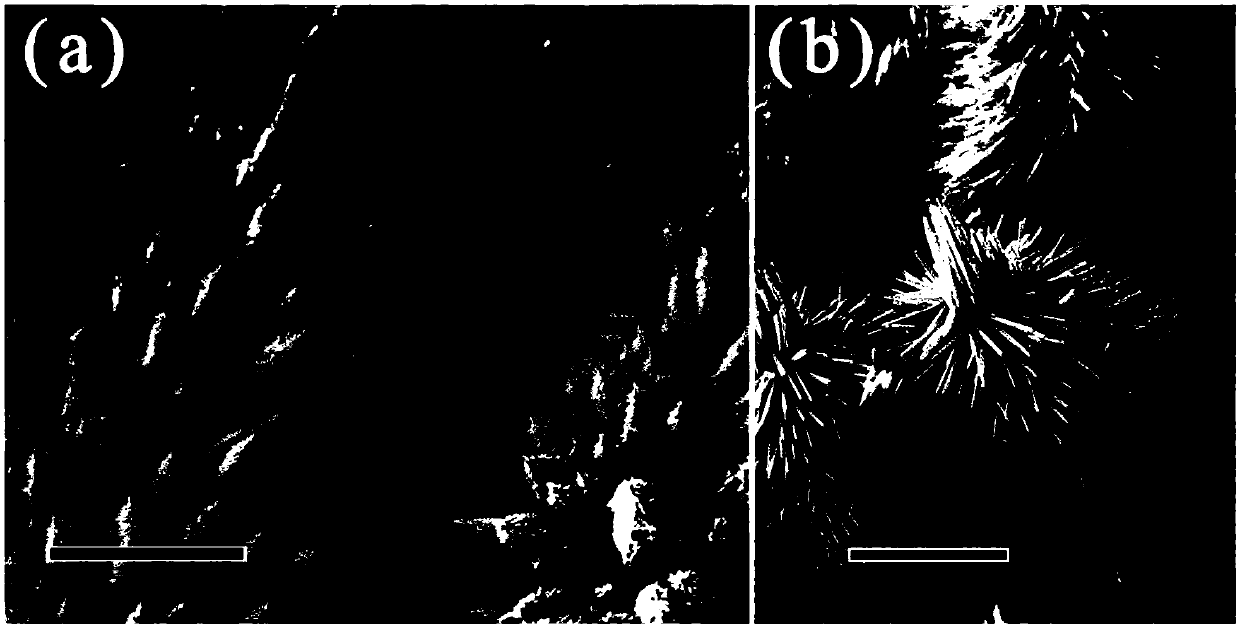

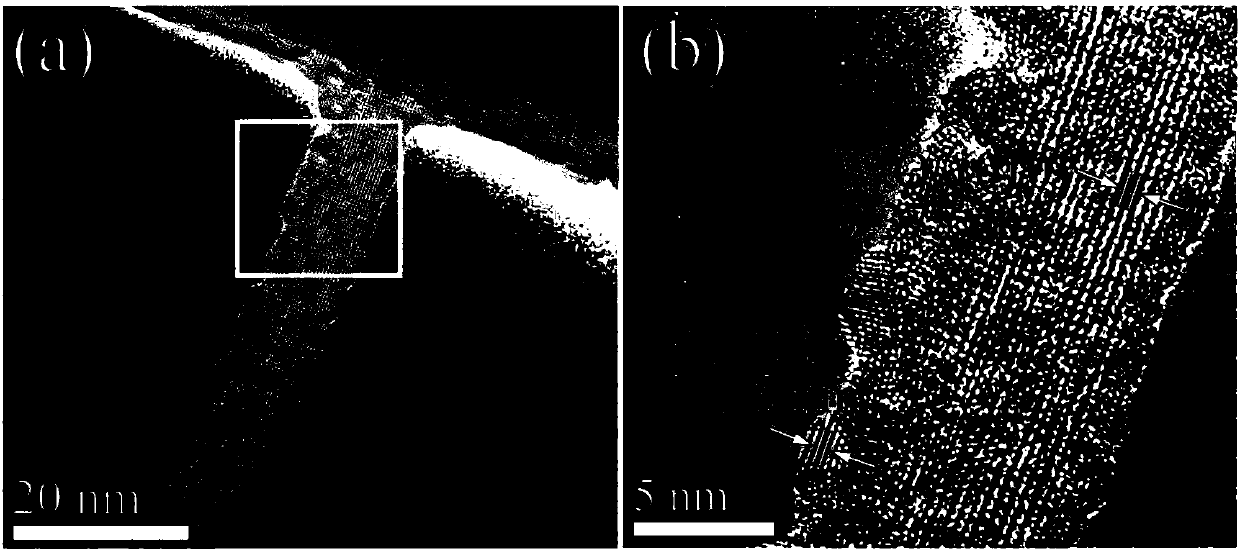

[0037] Example 1: W@W 18 o 49 Preparation of Thermally Driven Catalysts

[0038] In this embodiment, W@W 18 o 49 Taking thermally driven catalyst as an example to describe in detail, the W@W 18 o 49 The preparation method of thermally driven catalyst comprises the following steps:

[0039] (1) Connect the tungsten boat to the evaporation electrode of the vacuum thermal evaporation coating machine, and add 0.5g of tungsten powder (purity 99.95%) into the tungsten boat, and then place the carbon fiber cloth on the top of the tungsten boat to make the carbon fiber cloth and tungsten The distance between the boats is 2-100 mm.

[0040] (2) Turn on the mechanical pump to vacuumize the vacuum coating chamber for 20 minutes.

[0041] (3) Feed oxygen (purity 99.95%) and inert gas (purity 99.95%) into the vacuum coating cavity with a flow ratio of 1:100, and keep for 20 minutes.

[0042] (4) Continuously feed oxygen and inert gas into the vacuum coating chamber, turn on the ...

Embodiment 2

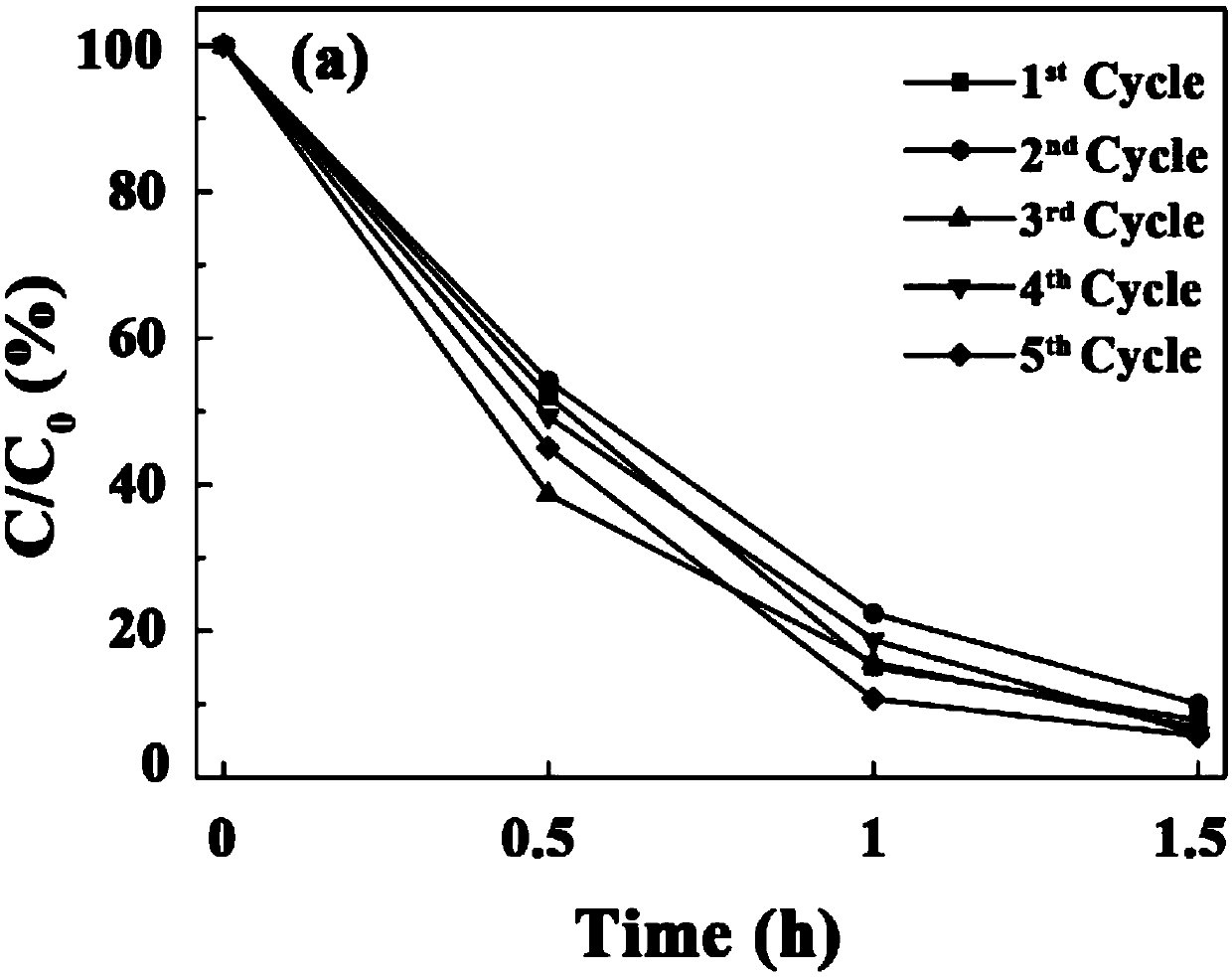

[0051] Example 2: Using infrared radiation heat to drive catalytic degradation of dye molecules and its repeated cycle under infrared irradiation test

[0052] Get the coated W@W prepared in Example 1 18 o 49 Carbon fiber cloth for thermally driven catalyst (area 1.0cm 2 ) as a catalyst sample, join in the methyl orange solution (concentration 0.12mmol / L) of 10ml, then place the methyl orange solution in the infrared oven that a 250W infrared light bulb is housed and irradiate for 1.5 hours, test formazan every 0.5 hours The ultraviolet-visible absorption spectrum of the base orange solution, and the measured data were used as the characteristic curve of the concentration of methyl orange over time. Under the irradiation of infrared light, the temperature of the methyl orange solution rose from room temperature 30°C to 70°C and then stabilized.

[0053] see image 3 , which is a characteristic curve diagram of the concentration of methyl orange solution changing with t...

Embodiment 3

[0057] Example 3: Experiments on catalytic degradation of dye molecules driven by ambient heat and their repeated cycles in a dark environment

[0058] Get 4 pieces of W@W plated that embodiment 1 makes 18 o 49 Carbon fiber cloth for thermally driven catalyst (area 1.0cm 2 ) as catalyst samples were added to 4 bottles of 10ml methyl orange solution (concentration 0.12mmol / L), and then the 4 bottles of methyl orange solution were placed in 5°C, 25°C, 50°C, 75°C matte After 20 hours in the environment, the ultraviolet-visible absorption spectra of 4 bottles of methyl orange solutions were tested respectively, and the measured data were used as the characteristic curve of the concentration of methyl orange with temperature.

[0059] see Figure 5 , which is a comparison chart of catalytic performance at different temperatures in the repeated cycle test of catalytic degradation of dye molecules in a light-free environment in this embodiment. It can be seen from the figure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com