Treatment method of nanofiltration concentrated water of refuse leachate

A technology for waste permeate and a treatment method, which is applied in the field of waste permeate nanofiltration concentrated water treatment, can solve the problems of difficulty in meeting the discharge index requirements, high evaporation process costs, unbearable for enterprises, etc. The effect of strong resistance to water impact and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

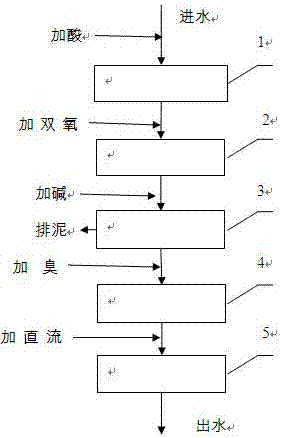

[0030] Nanofiltration concentrated water produced during the treatment of waste permeate in a waste incineration plant: the COD is 3600mg / L, and the salt content is 34000mg / L.

[0031] The treatment method provided by the present invention is used for treatment: the waste water is adjusted to 2.0 by adding sulfuric acid, and then enters the iron-carbon micro-electrolysis unit 1 for initial oxidation. The oxidation reaction takes 120 minutes. During the reaction, acid is added to control the pH of the effluent to be 3.0, and the iron-carbon Add 10‰ hydrogen peroxide to the micro-electrolysis effluent and enter the Fenton oxidation unit 2 for secondary oxidation. The oxidation time of the wastewater in the Fenton oxidation unit 2 is 60 minutes. The Fenton oxidation effluent is added with lye to adjust the pH to 9.0 and then enters the flocculation and sedimentation unit 3. Ferric ions in the wastewater form iron hydroxide flocs to precipitate, and the precipitate is discharged fr...

Embodiment 2

[0034] Nanofiltration concentrated water produced during the treatment of waste permeate in a waste treatment plant: COD is 1600mg / L, and salt content is 21800mg / L.

[0035] The treatment method provided by the present invention is used for treatment: the wastewater is adjusted to 2.5 by adding sulfuric acid, and then enters the iron-carbon micro-electrolysis unit 1 for initial oxidation, and the oxidation reaction is 60 minutes. During the reaction, acid is added to control the pH of the effluent to be 3.5, and the iron-carbon Add 4‰ hydrogen peroxide to the micro-electrolysis effluent and enter the Fenton oxidation unit 2 for secondary oxidation. The oxidation time of the wastewater in the Fenton oxidation unit 2 is 30 minutes. The Fenton oxidation effluent is added with lye to adjust the pH to 8.5 and then enters the flocculation and sedimentation unit 3. Ferric ions in the waste water form ferric hydroxide flocs to precipitate, and the precipitate is discharged from the bot...

Embodiment 3

[0038] The concentrated nanofiltration water produced during the treatment of waste permeate in a waste incineration plant has a COD of 800mg / L and a salt content of 19000mg / L.

[0039] The treatment method provided by the present invention is used for treatment: the wastewater is adjusted to 3.0 by adding sulfuric acid, and then enters the iron-carbon micro-electrolysis unit 1 for initial oxidation, and the oxidation reaction is 30 minutes. During the reaction, acid is added to control the pH of the effluent to be 4.0, and the iron-carbon Add 2‰ hydrogen peroxide to the micro-electrolysis effluent and enter the Fenton oxidation unit 2 for secondary oxidation. The oxidation time of the wastewater in the Fenton oxidation unit 2 is 30 minutes. The Fenton oxidation effluent is added with lye to adjust the pH to 8.0 and then enters the flocculation and sedimentation unit 3. Ferric ions in the wastewater form iron hydroxide flocs to precipitate, and the precipitate is discharged fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com