Preparation method of sulfonamides compound

A technology for sulfonamides and compounds, applied in the field of preparation of sulfonamide compounds, can solve problems such as limiting wide application, and achieve the effects of high atom economy, stable process conditions and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

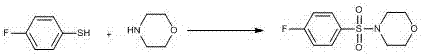

Image

Examples

Embodiment 1

[0033]

[0034] At room temperature, p-methylthiophenol (1.24 g, 10 mmol), morpholine (1.75 ml, 20 mmol), acetonitrile (20 mL) and diiodine pentoxide (10 mmol) were successively added into a 50 mL round bottom flask. Then, the reaction mixture was stirred at 60 °C for 12 h (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product sulfonamide compound (white solid 1.95 g, yield 81%).

[0035] 1 H NMR (CDCl 3, 500 MHz, ppm): δ 7.66 (d, J = 8.3 Hz, 2H), 7.37 (d, J =8.0 Hz, 2H), 3.76 (t, J = 4.7 Hz, 4H), 3.00 (t, J = 4.8 Hz, 4H), 2.47 (s,3H); C 13 NMR (CDCl 3 , 125MHz, ppm): δ 143.9, 132.1, 129.7, 127.9, 66.1, 46.0, 21.6; HRMS calc. for C 11 h 15 NO 3 SNa (M+Na) + , 264.0670; found, 264.0675.

Embodiment 2

[0037]

[0038] At room temperature, thiophenol (1.03ml, 10mmol), morpholine (1.75ml, 20mmol), acetonitrile (20 mL) and diiodine pentoxide (10 mmol) were successively added into a 50 mL round bottom flask. Then, the reaction mixture was stirred at 60 °C for 12 hours (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product sulfonamide compound (yellow solid 1.87g, yield 82%).

[0039] 1 H NMR (CDCl 3 , 500 MHz, ppm): δ 7.77-7.75 (m, 2H), 7.65-7.62 (m, 1H),7.58-7.55 (m, 2H), 3.75 (t, J = 4.7 Hz, 4H), 3.01 (t, J = 4.8 Hz, 4H); 13 C NMR (CDCl 3 , 125 MHz, ppm): δ 135.1, 133.1, 129.1, 127.8, 66.1, 46.0; HRMS calc. for C 10 h 13 NO 3 SNa (M+Na) + , 250.0514; found, 250.0517.

Embodiment 3

[0041]

[0042] At room temperature, p-methoxythiophenol (1.23ml, 10mmol), morpholine (1.75ml, 20mmol), acetonitrile (20 mL) and diiodine pentoxide (10 mmol) were successively added into a 50 mL round bottom flask. Then, the reaction mixture was stirred at 60 °C for 12 hours (reaction detected by TLC). Then, the reaction was stopped and concentrated under reduced pressure to obtain a crude product. Finally, it was washed with a mixed eluent of petroleum ether and ethyl acetate, and flash column chromatography (silica gel column) obtained the corresponding product sulfonamide compound (2.20 g of yellow crystals, yield 85%).

[0043] 1 H NMR (CDCl 3 , 500 MHz, ppm): δ 7.70-7.69 (m, 2H), 7.02-7.01 (m, 2H), 3.89 (s, 3H), 3.74 (t, J = 4.7 Hz, 4H), 2.98 (t, J = 4.8 Hz, 4H); 13 C NMR (CDCl 3 , 125 MHz, ppm): δ 163.2, 130.0, 126.7, 114.3, 66.1, 55.7, 46.0; HRMScalc. for C 11 h 15 NO 4 SNa (M+Na) + , 280.0619; found, 280.0622.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com