High-corrosion-resistant high-strength steel bar and its converter manufacturing method

A high-corrosion-resistant, high-strength steel bar technology, applied in the manufacture of converters, etc., can solve the problems of large heat loss and large amount of alloy addition, and achieve the effects of reducing alloy cost, avoiding excessive temperature drop, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

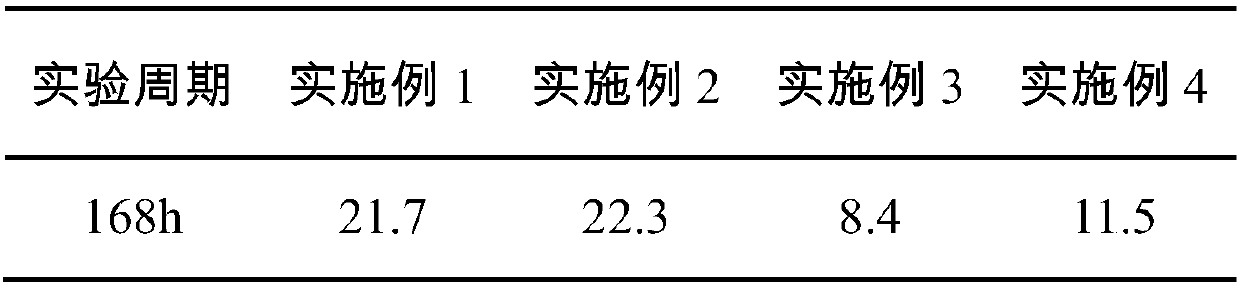

Examples

Embodiment 1

[0047] Using a 180t converter for smelting, the production steps are as follows:

[0048] (1) Desulfurization of molten iron: Take blast furnace molten iron with temperature T=1380°C, Si=0.3%, S=0.03%, and weight 162t, carry out desulfurization at KR desulfurization station, after desulfurization, S=0.001% in molten iron;

[0049] (2) Converter desiliconization and dephosphorization: the desulphurized molten iron obtained in step (1) is desiliconized and dephosphorized in a converter, adding 10kg / t of lime, 4kg / t of lightly burned dolomite, and 16kg / t of pellets, Control the basicity of the slag to 2.0; the oxygen pressure during the oxygen blowing process is 0.75MPa, the position of the blowing gun is 2.4m, and the position of the gun is reduced to 1.9m after 2 minutes of oxygen blowing, and the temperature is controlled at 1340-1360°C for 10 minutes after blowing oxygen. steel, obtain Si=0.01%, P=0.03% semi-steel molten steel;

[0050] (3) Converter decarburization and heat...

Embodiment 2

[0056] Using a 180t converter for smelting, the production steps are as follows:

[0057] (1) Desulfurization of molten iron: take temperature T=1405°C, Si=0.27%, S=0.033%, and weight 162.5t blast furnace molten iron, desulfurize at KR desulfurization station, after desulfurization, S=0.001% in molten iron;

[0058] (2) Desiliconization and dephosphorization of the converter: desiliconization and dephosphorization of the desulfurized hot metal obtained in step (1) in the converter, adding lime 11kg / t, lightly burned dolomite 3.5kg / t, pellets 19.5kg / t t, control the slag basicity to 2.0; the oxygen pressure during the oxygen blowing process is 0.8MPa, the blowing gun position is 2.4m, after 2 minutes of oxygen blowing, the gun position is reduced to 1.8m, and the oxygen blowing is controlled at 1330-1340°C for 7 minutes After tapping, obtain semi-steel molten steel with Si=0.008%, P=0.015%;

[0059] (3) Converter decarburization and heating: put the semi-steel molten steel obt...

Embodiment 3

[0065] Using a 180t converter for smelting, the production steps are as follows:

[0066] (1) Desulfurization of molten iron: Take blast furnace molten iron with temperature T=1380°C, Si=0.25%, S=0.04%, and weight 163t, and desulfurize it at the KR desulfurization station. After desulfurization, S=0.005% in molten iron;

[0067] (2) Desiliconization and dephosphorization of the converter: desiliconization and dephosphorization of the desulfurized hot metal obtained in step (1) in the converter, adding lime 8kg / t, lightly burned dolomite 5.5kg / t, pellets 13.5kg / t t, the basicity of the slag is controlled to be 1.5; the oxygen pressure during the oxygen blowing process is 0.7MPa, the position of the blowing gun is 2.4m, and the position of the gun is reduced to 2.1m after 2 minutes of oxygen blowing, and the oxygen blowing is controlled at a temperature of 1330-1350°C for 5 minutes After tapping, obtain semi-steel molten steel with Si=0.008%, P=0.025%;

[0068] (3) Converter de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com