A kind of 700mpa high-strength hot-rolled H-shaped steel and its preparation method

A H-shaped steel, high-strength technology, applied in the field of metallurgy, can solve the problems that cannot reach the control level of plate production, limit the production of high-strength hot-rolled H-shaped steel, and restrict the development of high-strength H-shaped steel, and achieve low production costs and alloy recovery. Stabilize and reduce self-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

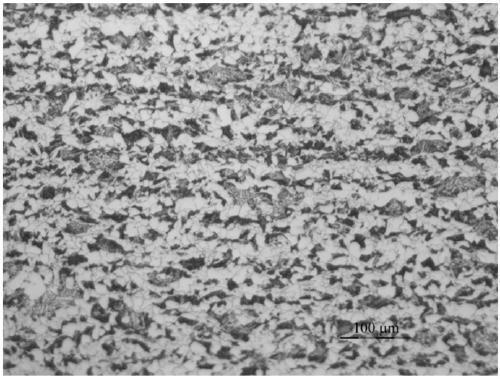

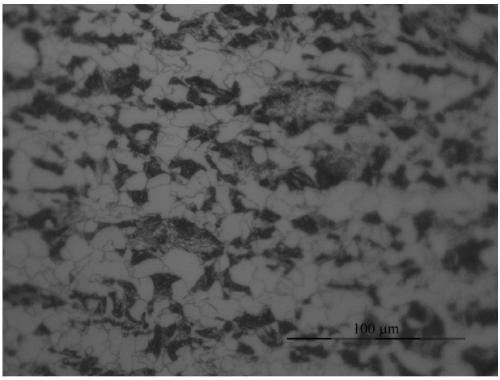

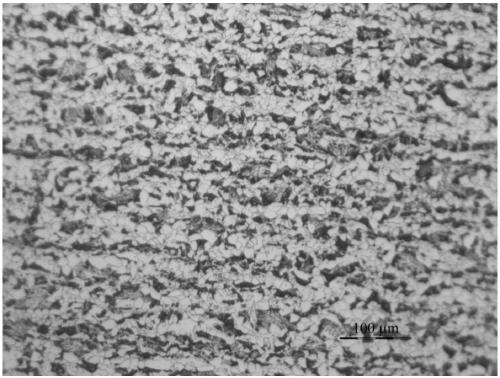

Image

Examples

Embodiment

[0039] The process route is:

[0040] Hot metal pre-desulfurization → converter smelting → near-final shaped billet full protection continuous casting → 1-3 rolling mill layout type production line rolling → inspection and storage.

[0041] Main technological measures of preparation method:

[0042] (1) When the molten iron arrives at the desulfurization station, the arsenic content of the molten iron into the furnace is less than 80ppm; the sulfur content in the molten iron after desulfurization is less than or equal to 0.008wt%.

[0043] (2) Converter smelting: Adding 3.0~3.5kg / ton of silicon, calcium and barium per ton of steel to deoxidize in the process of putting steel. Silicon manganese, medium carbon ferromanganese, copper particles, nickel plates, medium carbon ferrochrome and ferroniobium are used for alloying, and the alloy composition is controlled according to the middle limit; copper particles and nickel plates are added with the charge, and the remaining alloys are disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com