Water-saving dust removal and sewage discharge device for chimney

A technology of sewage discharge device and chimney, which is applied in the direction of using liquid separation agent, lighting and heating equipment, and dispersed particle separation, etc., can solve the problems of large smoke and dust in power plants, environmental pollution, etc., and achieve environmental protection, simple and convenient operation and control, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

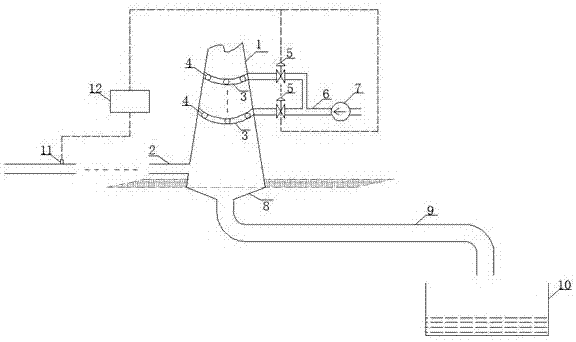

[0019] Embodiment 1: as figure 1 As shown, a water-saving chimney dust removal and sewage discharge device includes a chimney main system composed of a chimney 1 and a smoke inlet pipe 2, a dust removal water pipe 3, an atomizing nozzle 4, a solenoid valve 5, a water inlet pipe 6, a water supply pump 7, and a smoke concentration detection A chimney dust removal system composed of a device 11 and a controller 12, a chimney sewage discharge system composed of a sewage funnel 8, a sewage pipe 9 and a sewage pool 10;

[0020] The smoke inlet pipe 2 in the chimney body system is fixed below the side of the chimney 1; One end of the water inlet pipe 6 is connected to the dust removal pipe 3, and the other end is connected to the treated waste water in the power plant through the water pump 7. Several atomizing nozzles 4 are uniformly installed on the dust removal pipe 3, and the solenoid valve 5 is installed on the water inlet pipe 6. The valve 5 is connected with the controller 12...

Embodiment 2

[0021] Embodiment 2: wherein the dust removal water pipe 3 is fixed on the outer wall of the chimney 1 through a bracket, so as to facilitate the installation and maintenance of the dust removal water pipe 3, a through hole is drilled on the outer wall of the chimney 1, and the atomizing nozzle 4 is fixed on the dust removal water pipe 3 and runs through the chimney The through hole on 1 extends into the chimney 1, wherein the atomizing nozzle 4 is resistant to high temperature and corrosion and is threadedly connected with the dust removal water pipe 3, and the dust removal water pipe 3 and the water inlet pipe 6 are also threaded. Repair and maintenance of components.

Embodiment 3

[0022] Embodiment 3: The dust removal water pipes 3 are installed in two to four rows, and evenly installed at 5-8m above the smoke inlet pipe, which is beneficial to improve the dust removal efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com