Electrochemical biosensor for detecting Salmonella typhimurium and preparation method thereof

A biosensor, Salmonella technology, applied in the field of biosensors, can solve the problems of complex instrument operation and long time-consuming, and achieve the effects of good repeatability, improved sensitivity, and sensitive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

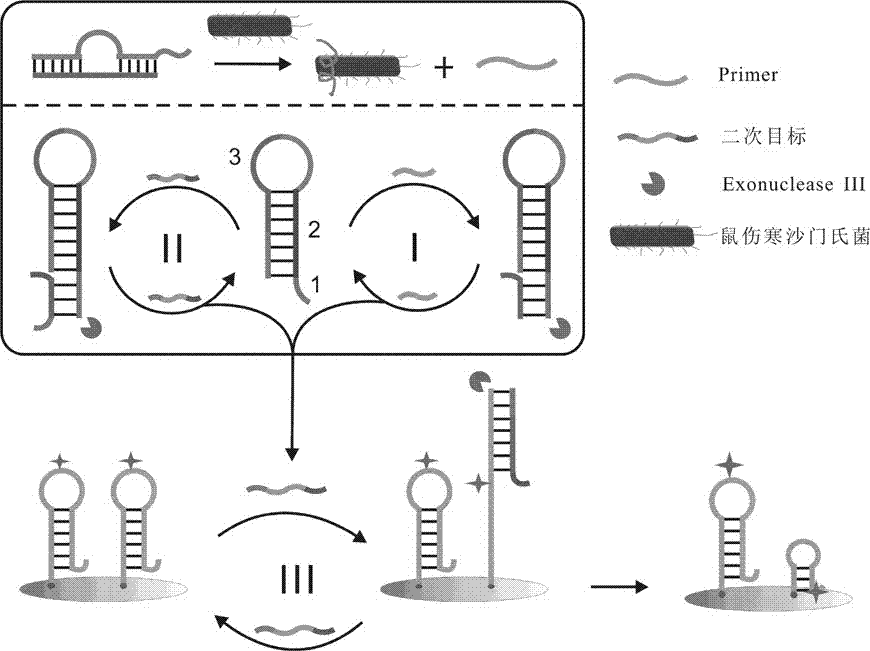

[0045] The preparation method of described biosensor comprises the following steps:

[0046] (1) Pretreatment of the electrodes;

[0047] (2) Modification of HAP2 to the electrode surface;

[0048] (3) Modification of homogeneous reaction products onto the electrode surface.

[0049] In the preparation method, the operation steps of modifying HAP2 onto the electrode surface are preferably as follows: 10 μL of HAP2 (10 μM) is added dropwise to the pretreated electrode surface, and incubated at 37 °C for 2 h.

[0050] In the preparation method, the preferred steps of modifying the homogeneous reaction product onto the electrode surface are as follows:

[0051] (1) Mix 8 μL sterile water, 2 μL 10× NEBuffer buffer (10 mM Bis Tris Propane-HCl, 10 mM MgCl 2 ,1 mM DTT, pH 7.0), 2 μL aptamer (1 mM), 2 μL primer (1 mM), 2 μL HAP1 (10mM), 2 μL Exonuclease Ⅲ (20 U / μL) and 2 μL of the target substance to be tested were added Place in a centrifuge tube, shake for 30 s, and incubate in ...

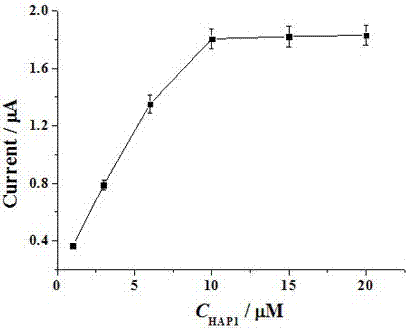

Embodiment 1

[0058] The main steps of the electrode modification process are as follows:

[0059] a. The gold electrode is first polished in 0.3 and 0.05 µm alumina slurry until it becomes a mirror surface, and then rinsed repeatedly with PBS and secondary water;

[0060] b. Add 10 μL of HAP2 (10 μM) dropwise to the electrode surface and incubate at 37 °C for 2 h. Fix the sulfhydryl chains to the electrode surface through Au-S bonds;

[0061] So far, the modification process of the electrode has come to an end. The following describes the reaction in the homogeneous solution and the main steps in the homogeneous reaction:

[0062] a. Mix 8 μL sterile water, 2 μL 10× NEBuffer buffer (10 mM Bis Tris Propane-HCl, 10 mMMgCl 2 ,1 mM DTT, pH 7.0), 2 μL aptamer (1 mM), 2 μL primer (1 mM), 2 μL HAP1 (1 μM, 3 μM, 6 μM, 10 μM, 15 μM, 20 μM), 2 μL Add Exonuclease III (20 U / μL) and 2 μL of the target substance to be tested into a centrifuge tube, shake for 30 s, and incubate in a 37 °C incubator fo...

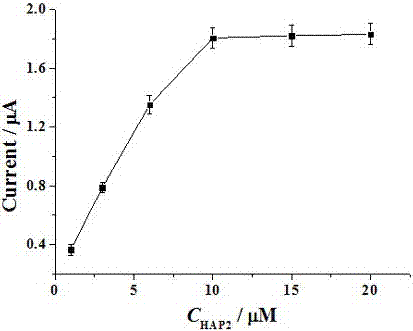

Embodiment 2

[0072] The main steps of the electrode modification process are as follows:

[0073] a. The gold electrode is first polished in 0.3 and 0.05 µm alumina slurry until it becomes a mirror surface, and then rinsed repeatedly with PBS and secondary water;

[0074] b. Add 10 μL of HAP2 (1 μM, 3 μM, 6 μM, 10 μM, 15 μM, 20 μM) onto the electrode surface respectively, and incubate at 37°C for 2 h. Fix the sulfhydryl chains to the electrode surface through Au-S bonds;

[0075] So far, the modification process of the electrode has come to an end. The following describes the reaction in the homogeneous solution and the main steps in the homogeneous reaction:

[0076] a. Mix 8 μL sterile water, 2 μL 10× NEBuffer buffer (10 mM Bis Tris Propane-HCl, 10 mMMgCl 2 ,1 mM DTT, pH 7.0), 2 μL aptamer (1 mM), 2 μL primer (1 mM), 2 μL HAP1 (10 μM), 2 μL Exonuclease III (20 U / μL) and 2 μL target Add to a centrifuge tube, shake for 30 s, and incubate in a 37°C incubator for 2 h;

[0077] b. Add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com