A method for detecting formaldehyde content in hemodialysis concentrate packaging material

A technology of hemodialysis and detection method, applied in the field of analytical chemistry, it can solve the problems of potential risk of patients and human carcinogenicity, and achieve the effect of high-accuracy measurement and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

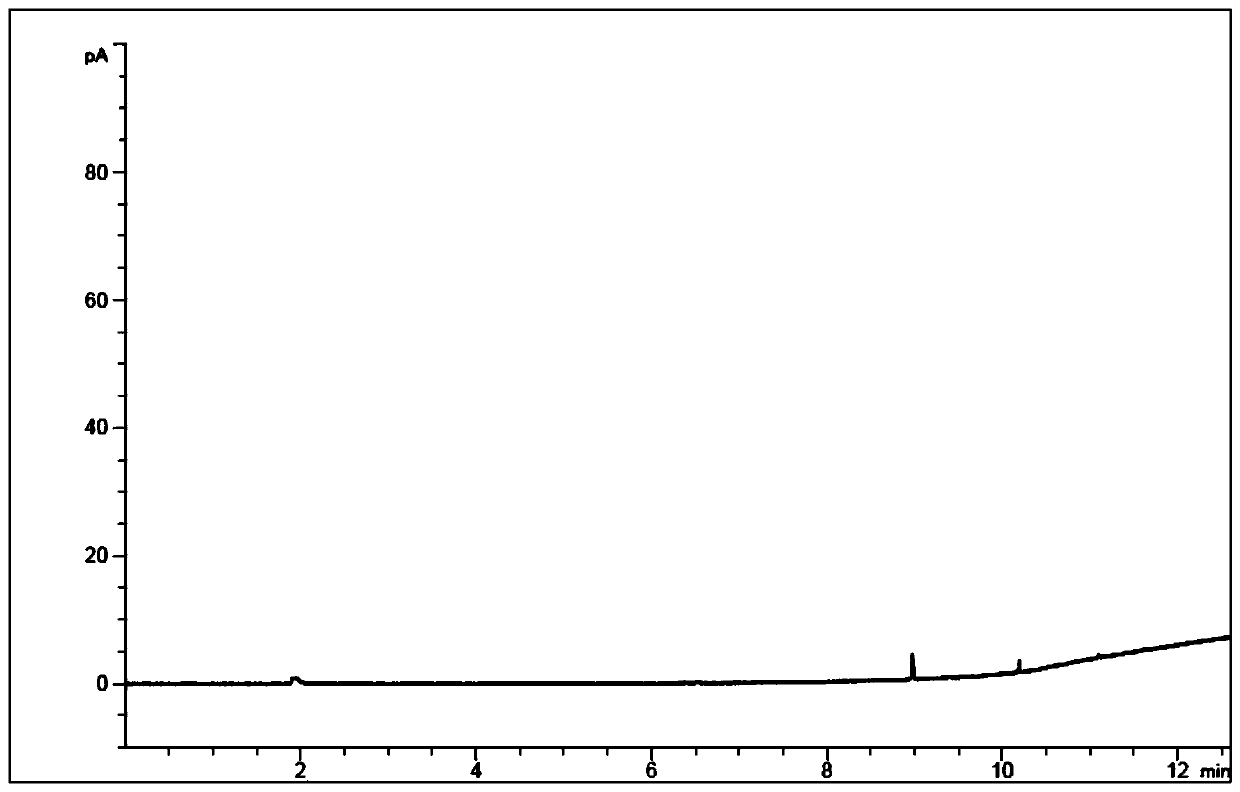

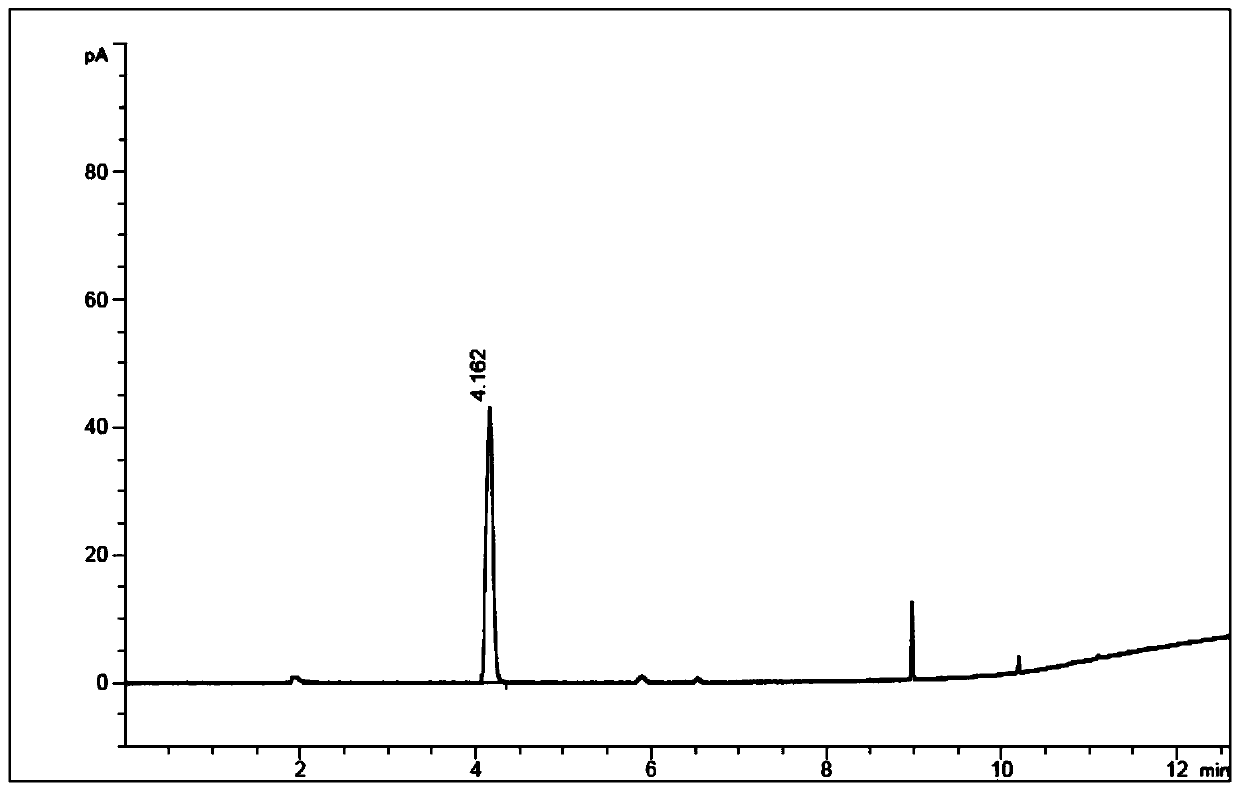

Image

Examples

Embodiment 1

[0064] Apparatus and conditions

[0065] Agilent 7890A gas chromatograph (equipped with FID detector); Chromatographic column: Agilent DB-FFAP, 60m×0.25mm, 0.50μm; Carrier gas flow rate: 1.5ml / min; Column temperature: starting temperature 60℃, maintain for 5 minutes, The temperature is increased to 175°C at a rate of 25°C per minute and maintained for 3.5 minutes; the injection port temperature is 150°C; the detector temperature is 200°C; the headspace bottle equilibrium temperature is 70°C, and the equilibrium time is 20 minutes; the sample volume is 1ml. The temperature of the headspace injection loop is 95°C, the temperature of the transfer line is 100°C, the injection pressure is 277kPa, and the injection pressure time is 1 minute.

[0066] Experimental steps

[0067] Cut the high-density polyethylene barrel of the hemodialysis concentrate packaging material into a certain size, into 0.5cm×0.5cm;

[0068] Wash the fragments of the high-density polyethylene bucket with soapy water...

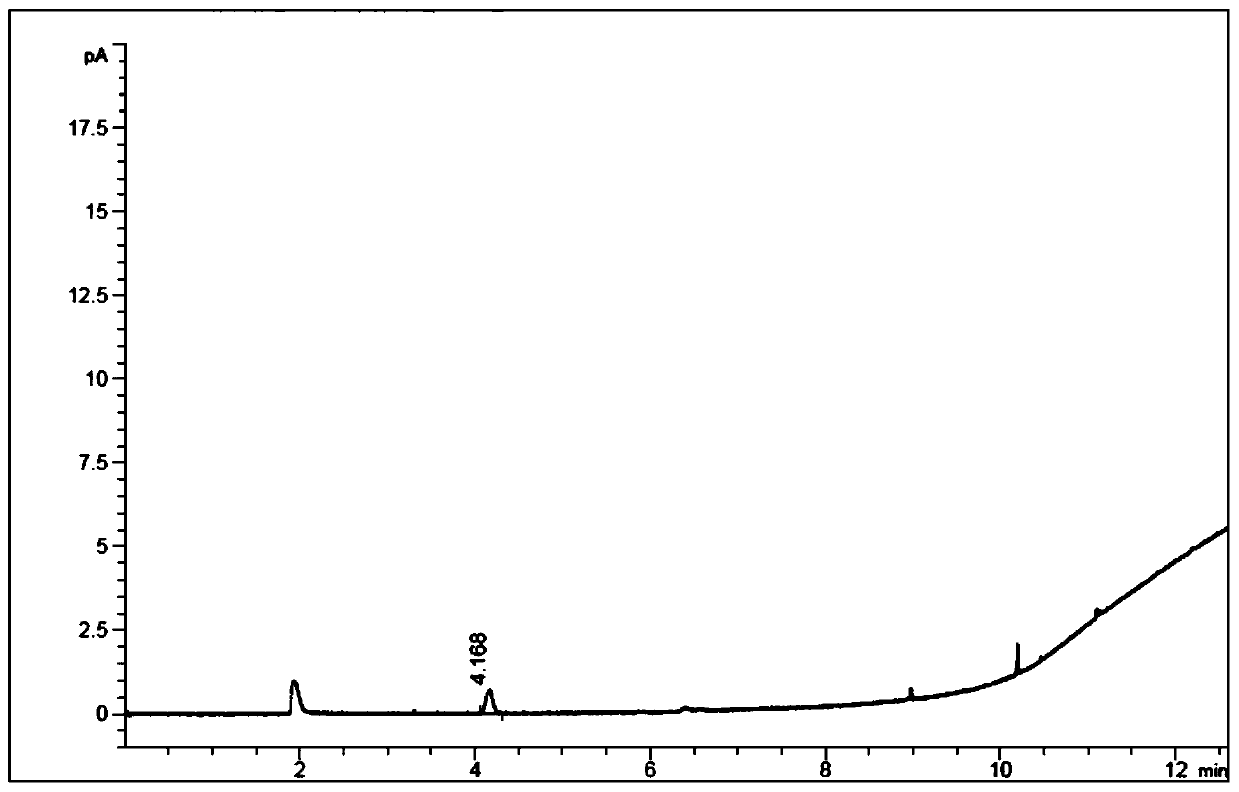

Embodiment 2

[0073] Apparatus and conditions

[0074] Agilent 7890A gas chromatograph (equipped with FID detector); Chromatographic column: Agilent DB-FFAP, 60m×0.25mm, 0.50μm; Carrier gas flow rate: 1.5ml / min; Column temperature: starting temperature 60℃, maintain for 5 minutes, The temperature is increased to 175°C at a rate of 25°C per minute and maintained for 3.5 minutes; the injection port temperature is 150°C; the detector temperature is 200°C; the headspace bottle equilibrium temperature is 70°C, and the equilibrium time is 20 minutes; the sample volume is 1ml. The temperature of the headspace injection loop is 95°C, the temperature of the transfer line is 100°C, the injection pressure is 277kPa, and the injection pressure time is 1 minute.

[0075] Experimental steps

[0076] Cut the high-density polyethylene inner cover of the hemodialysis concentrate packaging material into a certain size, into 0.5cm×0.5cm;

[0077] Wash the high-density polyethylene inner cover fragments with soapy wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com