PVC card substrate

A card base and base material technology, applied in the field of PVC hard film technology equipment, can solve the problems of card body failure, poor signal transmission contact, softening and deformation, etc., and achieve the effects of low manufacturing cost, optimized formula design, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

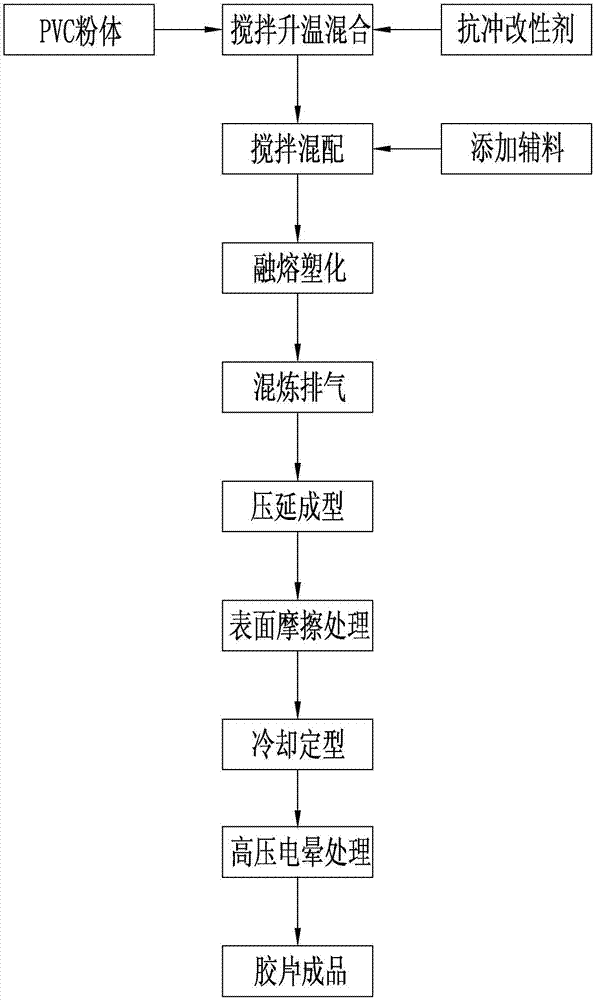

[0026] according to figure 1 , the invention provides a kind of PVC card base material, comprise component formula and carry out production technological process according to described component formula, it is characterized in that:

[0027] The component formula includes:

[0028]

[0029]

[0030] The PVC resin is a powder with a degree of polymerization of 800; the impact modifier is a styrene-methylstyrene extract; the stabilizer is isooctyltin dimethyl ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap