Method for measuring content of humic acid in oil-containing sludge in oilfield

A determination method and humic acid technology, applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of cumbersome procedures, poor homogeneity, complicated operation, etc., and achieve broad application prospects and short test time , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

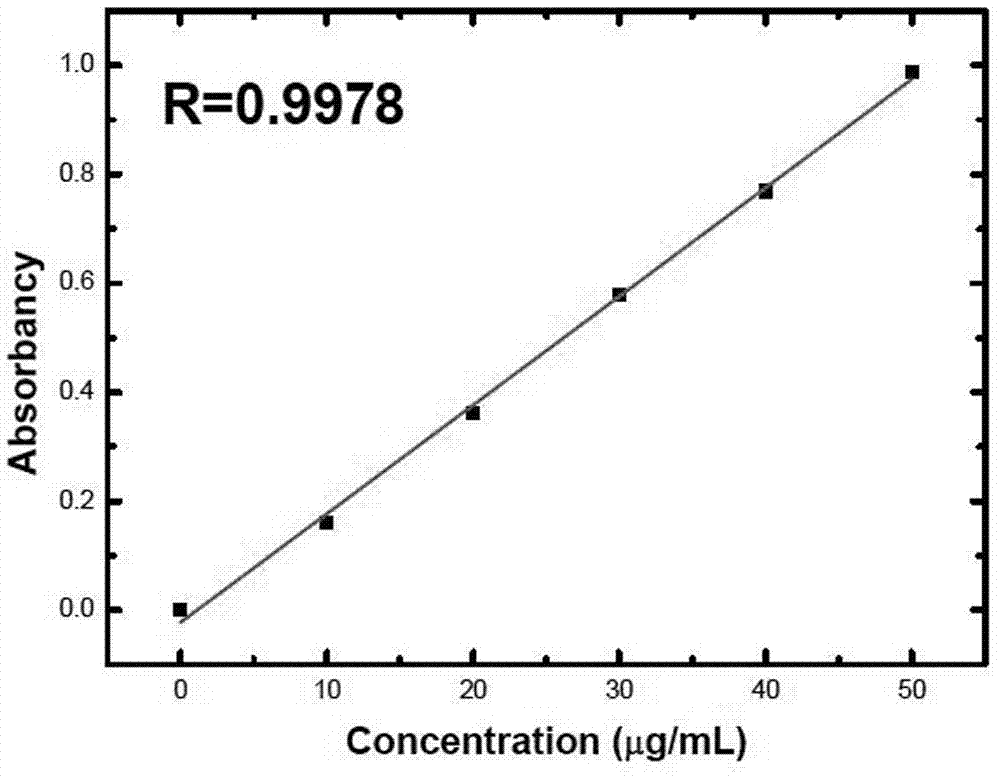

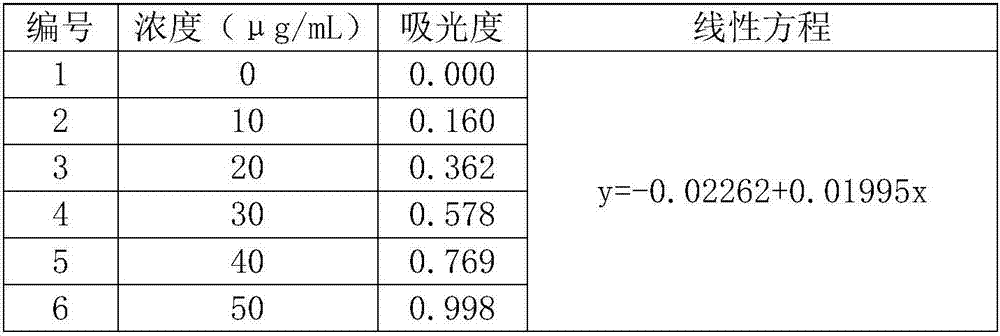

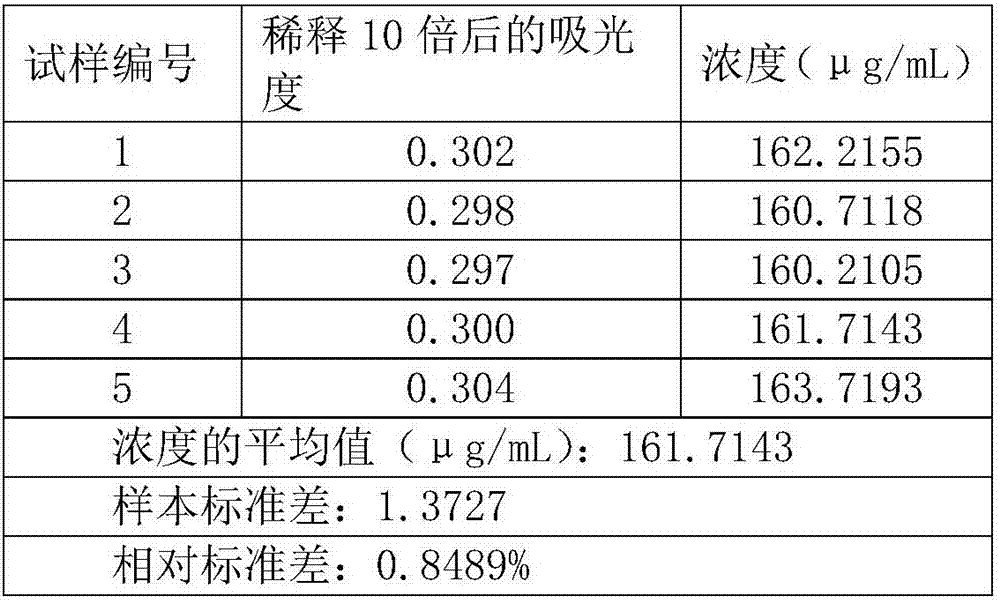

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

[0029] 1. Reagent preparation

[0030] 1) 0.05mol / L sodium hydroxide solution: Weigh 2.0g of sodium hydroxide and dissolve in water, dilute to 1L;

[0031] 2) Sodium hydroxide (0.1mol / L)-sodium pyrophosphate (0.1mol / L) mixed extract (pH=13): Weigh 4.0g sodium hydroxide and 44.6g sodium pyrophosphate (with 10 crystal water) Soluble in water, dilute to 1L;

[0032] 3) 500μg / mL humic acid standard solution: Accurately weigh 0.2500g sodium humate (analytical pure) and dissolve it in 200mL-300mL0.05mol / L sodium hydroxide solution, and dilute to 500.0mL volumetric flask;

[0033] 4) Blank reference solution: 10.00mL 5mol / L sodium hydroxide solution;

[0034] 5) 10μg / mL, 20μg / mL, 30μg / mL, 40μg / mL, 50μg / mL humic acid standard solution: accurately pipette 200μl, 400μl, 600μl, 800μl, 1000μl sodium humate with an adjustable volume pipette Put the standard solution in a 10.00mL vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com