Instant-prepared fried noodle and producing method of the noodle

A manufacturing method and technology of fried pasta, which is applied in the field of instant fried pasta and its manufacture, can solve the problems such as insignificant effect, and achieve the effect of good density and sufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The best mode for carrying out the present invention will be described in detail below by showing experimental examples and the like, and the present invention should not be limitedly interpreted based on the following test results. In addition, in this experimental example, the reduction effect of the fat content was compared with that of a general commercial product that has a liquid absorption process (a process of absorbing seasoning liquid or water after cooking), that is, the amount of sodium carbonate added is that of noodle raw material powder. 0.15% (w / w) control product, if the oil content is reduced by about 10% or more, it has a reducing effect. In addition, the method of measuring the oil content is based on the standard oil analysis test method established by the Japan Oil Chemical Society. The method of measuring the pH value of the dough and noodles is to dilute the sample 10 times in distilled water, grind and pulverize it with a mill for 1 minute to fo...

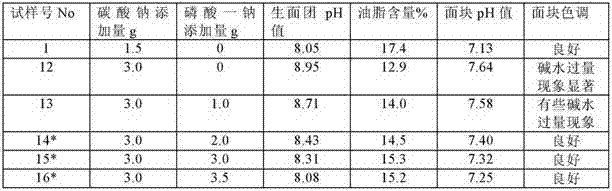

experiment example 1

[0046] [Experimental Example 1] (Influence of excessive amount of alkaline water and oil content in the case of changing the amount of sodium carbonate and adjusting the pH value with monosodium phosphate)

[0047] Add 20g of salt, a specified amount of sodium carbonate, and 350ml of an aqueous solution formed by adding monosodium phosphate (acidic substance) that can make the pH of the dough to about 8 to 1kg of noodle raw material powder composed of 850g of wheat flour and 150g of acetylated tapioca starch , mixed with a mixer for 15 minutes to make it fully and evenly mixed, then set aside for about 15 minutes, and measured the pH value of the dough at this time. Process it into a noodle strip shape with a continuous calendering calender, calender to a final thickness of 1.00mm, cut out the noodles with a No. 20 corner knife, and use a 600kg / m 3 Steam for 2 minutes per hour of normal steam (temperature in the steam cabinet is 99°C) to make it gelatinized, and after cooling,...

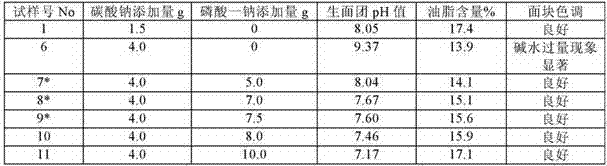

experiment example 2

[0051] [Experimental Example 2] (Effect of fat content in the case of lowering the pH value of dough with monosodium phosphate)

[0052] With the same method as Experimental Example 1, the amount of sodium carbonate added is 4g / kg, the added amount of monosodium phosphate as an acidic substance is further increased or decreased, and the fat content and the alkaline water of the noodle block under the situation of changing the pH value are excessive. Influence, the research is carried out in the same way as in Experimental Example 1. The results are shown in Table 2.

[0053] Table 2

[0054]

[0055] Compared with sample 1 which is an example of the prior art, sample 6 in which the amount of sodium carbonate added is 4 g / kg has the effect of reducing the fat content, but the excess of alkaline water is remarkable and is not at an edible level. In contrast, samples 7, 8, and 9, in which the pH of the dough was lowered by adding monosodium phosphate, reduced fat and oil by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com