Multi-tower-plate stream distribution in-diffusion vertical plug-flow photocatalysis reactor

A technology of photocatalytic reactors and catalytic reactors, applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve problems such as difficult to recycle, small amount of treated water, difficult to apply to industrial production, etc., to achieve Save time, prevent suspension, achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and examples. The examples are only used to explain the present invention, not to limit the scope of the present invention.

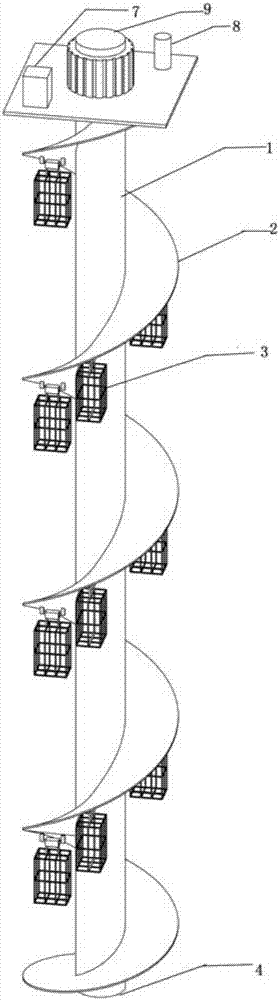

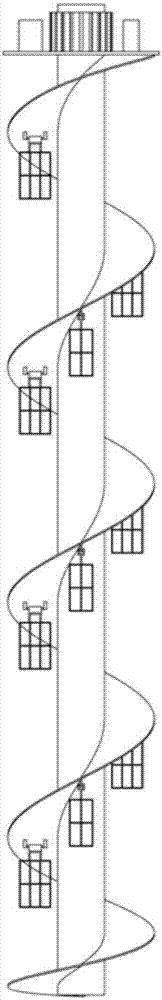

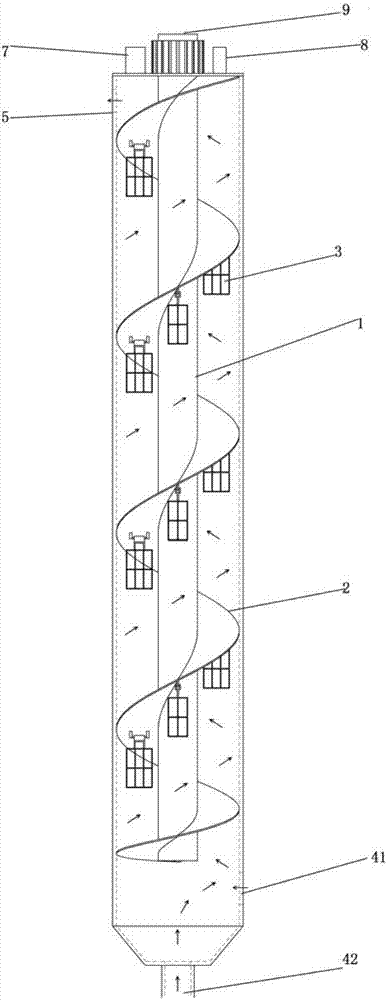

[0038] Such as Figure 1-7 Shown, a kind of vertical push-flow photocatalytic reactor of distribution flow inner diffusion on multi-tray, the lamp tube 9 that is attached with quartz sleeve 1 in the photocatalytic reactor lining, quartz sleeve 1 is coaxial with reactor, reaction From the bottom to the top of the reactor, there is a spirally rising tray 2 with the quartz sleeve 1 as the axis, and a plurality of catalyst trays 3 are suspended in the gap space between the upper and lower trays 2, and the water inlet 4 is located at the top of the photocatalytic reactor. In the lower part, the water outlet 5 is arranged on the upper part of the photocatalytic reactor. The catalyst tray 3 is net-shaped, evenly and spirally hung on the tray 2 in the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com