Cationic polyurethane, its preparation method, fabric pretreatment liquid and its application

A technology of cationic polyurethane and pretreatment liquid, which is applied in fiber treatment, textiles and papermaking, wear-resistant fibers, etc., and can solve problems such as the influence of fabric application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

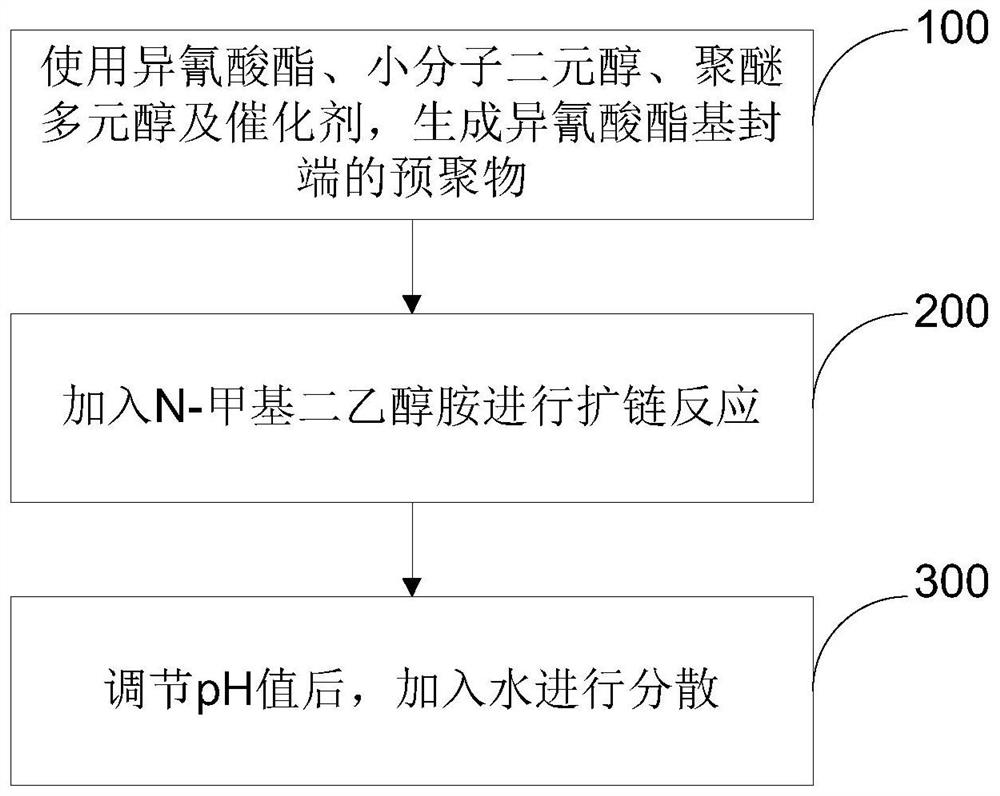

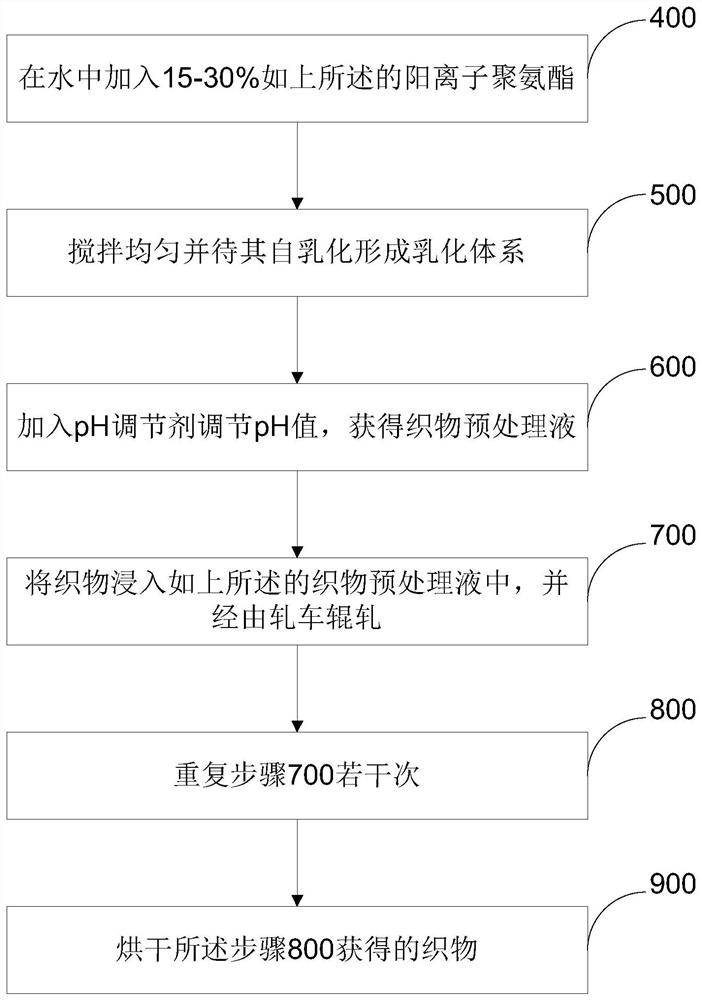

Method used

Image

Examples

Embodiment 1

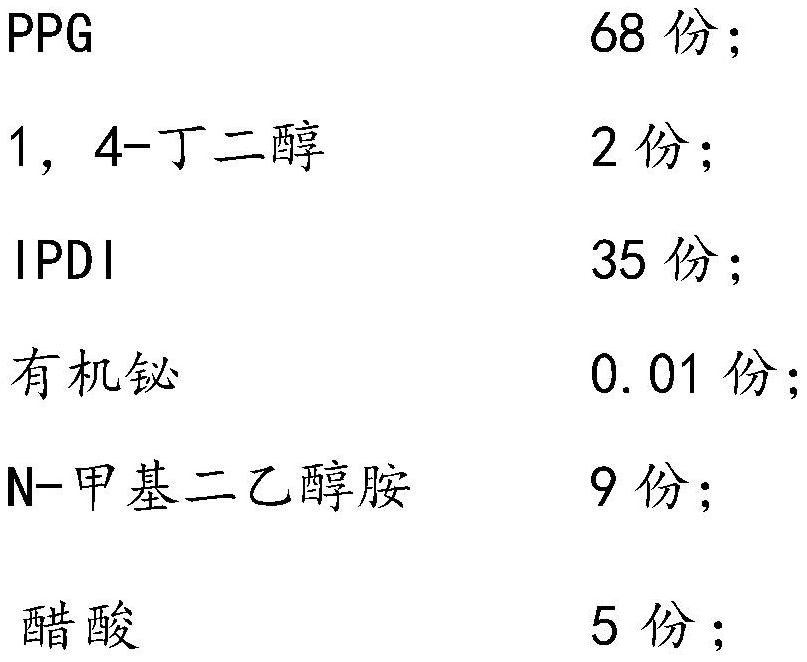

[0052] Embodiment 1 (as solid wool / fiber curing agent):

[0053]Preparation of cationic polyurethane: 68 parts of PPG, 2 parts of 1,4-butanediol, 35 parts of IPDI and 0.01 part of organic bismuth were reacted at 80-85° C. for 3-4 hours under nitrogen protection. Then, lower the temperature to 50-60°C, add 9 parts of N-methyldiethanolamine and react for 30-60 minutes. Finally, lower the temperature to 40°C, add 5 parts of acetic acid to react for 30 minutes, and then add water to disperse for 30 minutes.

[0054] Preparation of fabric pretreatment liquid: add pH adjuster, handle finishing agent, and prepared cationic polyurethane emulsion into a certain amount of water, stir well and prepare fabric pretreatment liquid.

[0055] Wherein, the pH of the fabric pretreatment liquid is 3-7. The concentration of the pH regulator is 0-5g / L, the concentration of the hand finishing agent is 0-80g / L, and the concentration of the cationic polyurethane emulsion is 5-30g / L. The pH regulat...

Embodiment 2

[0060] Example 2 (used as a powerful lifter):

[0061] Preparation of cationic polyurethane: 80 parts of PPG, 1 part of 1,4-butanediol, 25 parts of IPDI and 0.01 part of organic bismuth were reacted at 80-85° C. for 3-4 hours under nitrogen protection. Then, lower the temperature to 50-60°C, add 9 parts of N-methyldiethanolamine and react for 30-60 minutes. Finally, lower the temperature to 40°C, add 5 parts of acetic acid to react for 30 minutes, and then add water to disperse for 30 minutes.

[0062] Fabric pretreatment solution configuration: add the pH regulator and the prepared cationic polyurethane emulsion into a certain amount of water, stir evenly, and prepare the fabric pretreatment solution.

[0063] Wherein, the pH of the fabric pretreatment liquid is 3-7. The concentration of the pH regulator is 0-5g / L, and the concentration of the cationic polyurethane emulsion is 5-50g / L. The pH regulator is acetic acid, citric acid or acetic acid-sodium acetate.

[0064] Fa...

Embodiment 3

[0067] Embodiment 3 (as elastic finishing agent):

[0068] Preparation of cationic polyurethane: Under nitrogen protection, react 70 parts of PTMG, 1.5 parts of 1,4-butanediol, 20 parts of IPDI, 10 parts of HDI and 0.01 part of organic bismuth at 80-85°C for 3-4h. Then, lower the temperature to 50-60°C, add 8 parts of N-methyldiethanolamine and react for 30-60 minutes. Finally, lower the temperature to 40°C, add 4 parts of acetic acid to react for 30 minutes, and then add water to disperse for 30 minutes.

[0069] Preparation of fabric pretreatment liquid: add pH adjuster, silicone elastomer emulsion, and prepared cationic polyurethane emulsion into a certain amount of water, stir evenly, and prepare fabric pretreatment liquid.

[0070] Wherein, the pH of the fabric pretreatment liquid is 3-7. The concentration of the pH regulator is 0-5g / L, the concentration of the cationic polyurethane emulsion is 5-30g / L, and the silicone elastomer emulsion is 0-20g / L. The pH regulator i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com