Pure inorganic fire-retardant coating

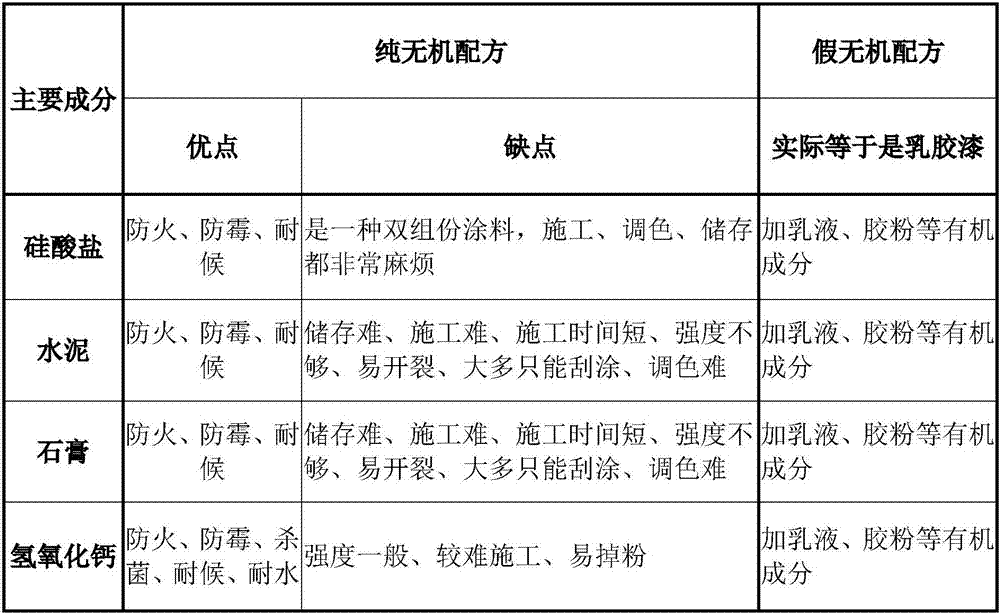

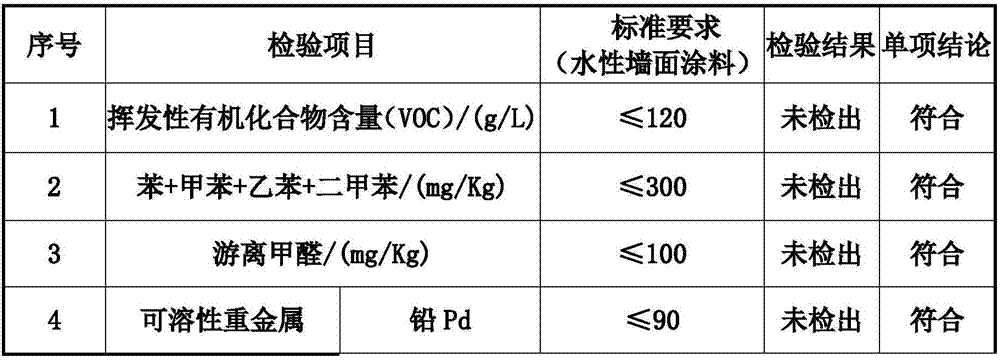

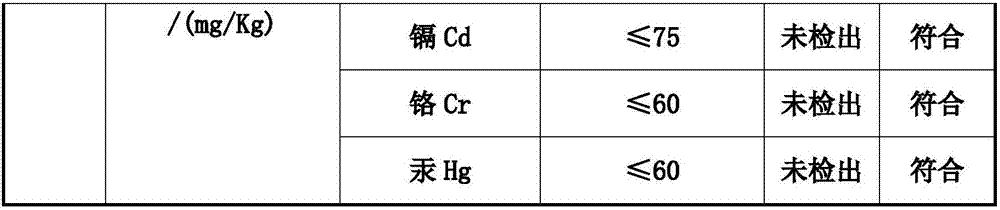

A fire retardant coating, inorganic technology, applied in the direction of fire retardant coatings, coatings, etc., can solve the problems of insufficient strength, difficult construction, difficult to achieve the desired effect of the coating, and achieve the effect of simple production process and good fireproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of pure inorganic fireproof coating mainly is made up of the raw material of following weight part: 30 parts of calcium hydroxide, 10 parts of silica sol, 0.1 part of sodium chloride, 5 parts of aluminum hydroxide, 3 parts of sepiolite, 3 parts of bentonite and 100 parts of water, the above-mentioned raw materials are mixed according to their respective weight parts, dispersed at high speed and filtered to obtain a finished product. Silica sol is silica sol with a concentration greater than 30%, calcium hydroxide is calcium hydroxide with a purity higher than 99% and a mesh size greater than 2000 mesh, and aluminum hydroxide is ultrafine and ultrawhite aluminum hydroxide with a purity higher than 99%.

Embodiment 2

[0026] Embodiment 2: a kind of pure inorganic fireproof coating mainly is made up of the raw material of following weight part: calcium hydroxide 55 parts, silica sol 20 parts, sodium chloride 2 parts, aluminum hydroxide 15 parts, sepiolite 4 parts, 4 parts of bentonite and 100 parts of water, the above-mentioned raw materials are mixed according to their respective weight parts, dispersed at high speed and filtered to obtain a finished product.

Embodiment 3

[0027] Embodiment 3: a kind of pure inorganic fireproof coating, it is mainly made up of the raw material of following weight part: calcium hydroxide 60 parts, silica sol 35 parts, sodium chloride 3 parts, aluminum hydroxide 25 parts, sepiolite 8 parts , 8 parts of bentonite and 100 parts of water, the above-mentioned raw materials are mixed, dispersed at high speed and filtered according to their respective parts by weight to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com