A preparation method of optimized gradation, low energy consumption and high concentration of coal-water slurry

A high-concentration water and coal-water slurry technology, applied in liquid carbon-containing fuels, petroleum industry, fuels, etc., can solve the problems of high energy consumption of grinding equipment, limited concentration of coal-water slurry, complex process, etc., and achieve good energy-saving effect, The effect of widening pulping coal types and simple pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

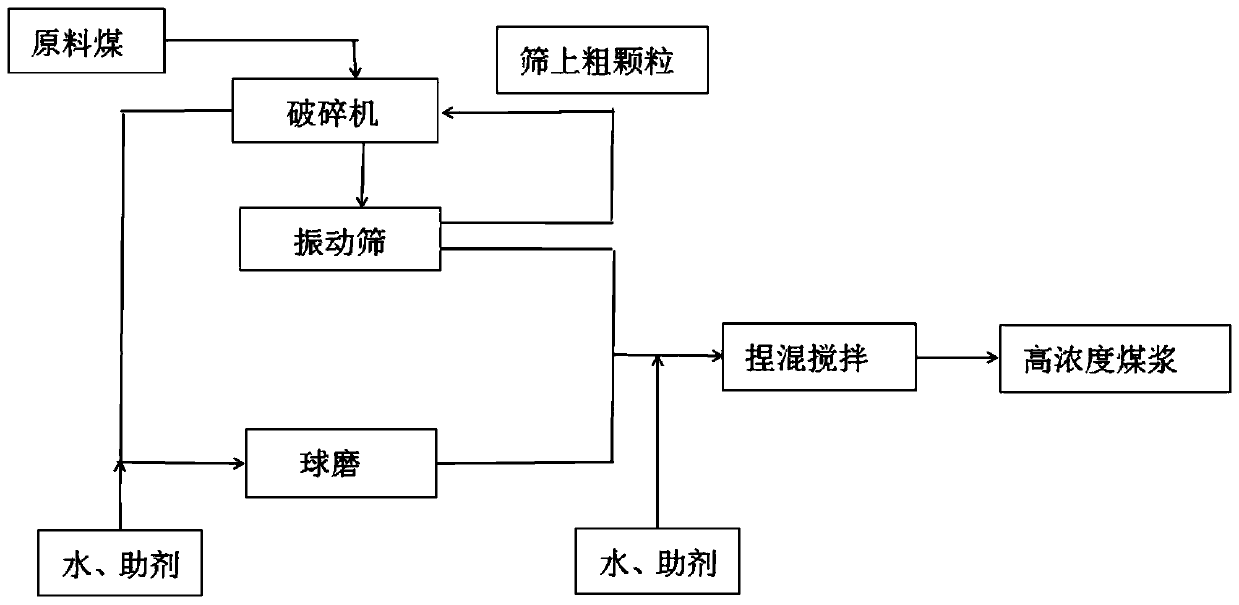

Method used

Image

Examples

Embodiment 1

[0025] (1) Coarse powder accounts for 50 parts, fine powder accounts for 50 parts, and naphthalene-based dispersant accounts for 0.4 part in the dry basis mass fraction of the prepared coal-water slurry;

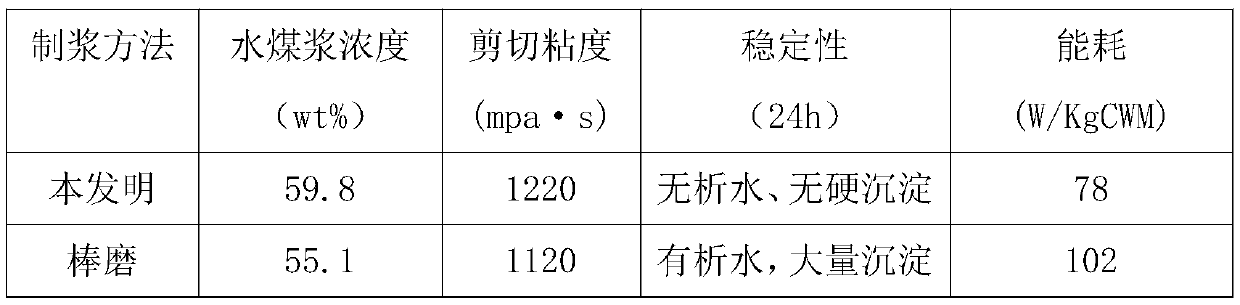

[0026] (2) The coal is crushed by the crocodile crusher and then passed through a 14-mesh sieve to obtain a coarse powder, and a fine slurry is obtained by an intermittent small ball mill, and the dried 75g Wangjiata coal coarse powder is slowly added to 175g and stirred A slurry with a wide particle size distribution (concentration of 42.3%, average particle size of 29.3 μm, 60 mesh, and 200 mesh passing rates of 99.8% and 92.3%, respectively) was obtained from the ultrafine slurry in the slurry. Slowly add the coarse powder of 83g Dongbo coal after drying into the superfine slurry in 167g stirring to make a slurry with wide particle size distribution (concentration is 49.5%, average particle diameter 28.2μm, 60 mesh, 200 mesh through 99.9% and 93.5% respectively), analyze ...

Embodiment 2

[0032] (1) Coarse powder accounts for 60 parts, fine powder accounts for 40 parts, and aliphatic dispersant accounts for 0.2 part in the dry mass fraction of the prepared coal-water slurry;

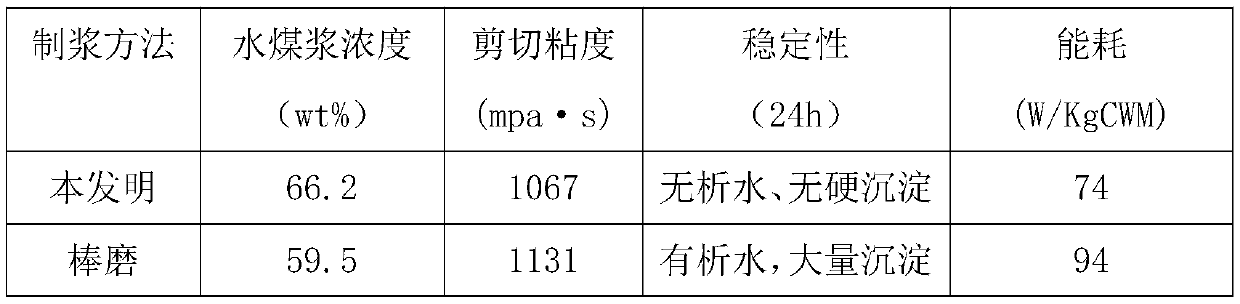

[0033] (2) The coal is crushed by a crocodile crusher and then passed through a 14-mesh sieve to obtain a coarse powder, and a fine slurry is obtained by an intermittent small ball mill, and the dried 130g of flat coal powder is slowly added to 170g of stirring A slurry with a wide particle size distribution (concentration of 50.0%, average particle size of 27.1 μm, 60 mesh, and 200 mesh passing rates of 99.9% and 94.1%, respectively) was obtained in the ultrafine slurry. Add 33g of water to 147g of ultrafine slurry (concentration is 41%, average particle size 26.9μm, 60 mesh, 200 mesh pass rate 99.8%, 95.8%), and add 90.5g of dried Zhundong coal while stirring Coarse powder was used to prepare a slurry with a wide particle size distribution. The viscosity, concentration and stability of ...

Embodiment 3

[0041] (1) Coarse powder accounts for 70 parts, fine powder accounts for 30 parts, and lignin dispersant accounts for 3 ‰ in the mass fraction of dry basis of the prepared coal-water slurry;

[0042](2) After the coal is crushed by the crocodile crusher, the coarse powder is obtained through a 14-mesh sieve, and a fine slurry is obtained by intermittent small-scale vibration grinding, and the coarse powder of 145g Erlin Rabbit Coal after drying is slowly added to the A slurry of wide particle size distribution (40.0% concentration, 26.8 μm average particle diameter, 99.9% and 94.8% passing rates of 60 mesh and 200 mesh respectively) was prepared in 155 g of stirring ultrafine slurry. Add 31g of water to 126g of ultra-fine slurry with a concentration of 40.2%, average particle size of 24.8μm, 60 mesh, and 200 mesh pass rates of 99.9% and 96.8%, respectively, and add 118g of dried Zhundong coal powder while stirring A slurry with a broad particle size distribution was produced. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com