Method for recovering polymerized phosphate by mixed combustion of phosphorus-containing waste

A technology of polymerized phosphate and mixed combustion, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of high cost, insufficient incineration, and reduce the utilization rate of phosphorus resources, and achieve the effect of improving incineration efficiency

Active Publication Date: 2017-08-18

ZHENJIANG JIANGNAN CHEM

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These existing treatment methods are costly and also reduce the utilization rate of phosphorus resources

[0003]

Patent 201210020303.0 discloses a two-stage incineration device, which includes an L-shaped furnace body connected with a vertical incinerator and a horizontal incinerator. It is characterized in that the vertical incinerator is divided into a combustion zone and a settling zone. Fuel burning guns and waste atomizing guns are installed in the area, and the waste liquid atomization and combustion are carried out in two steps, and the incineration is not sufficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

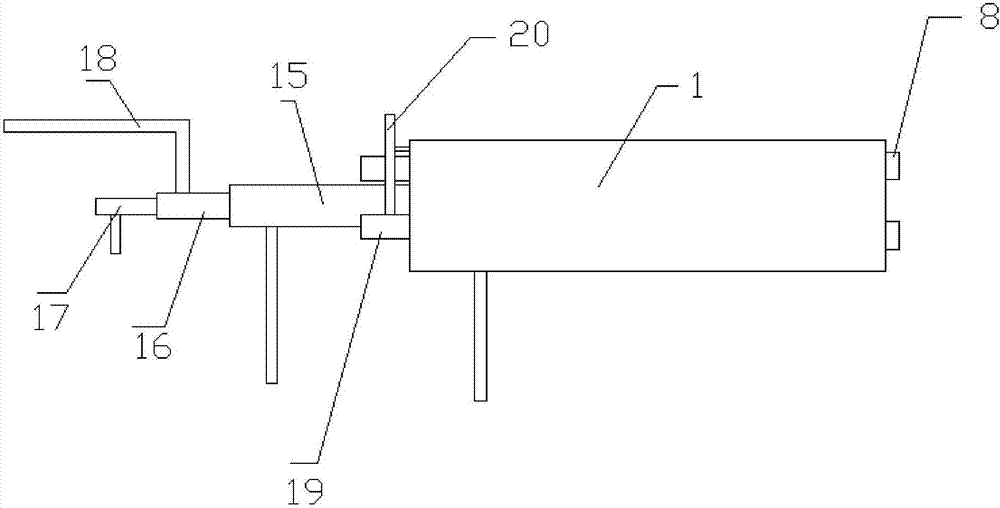

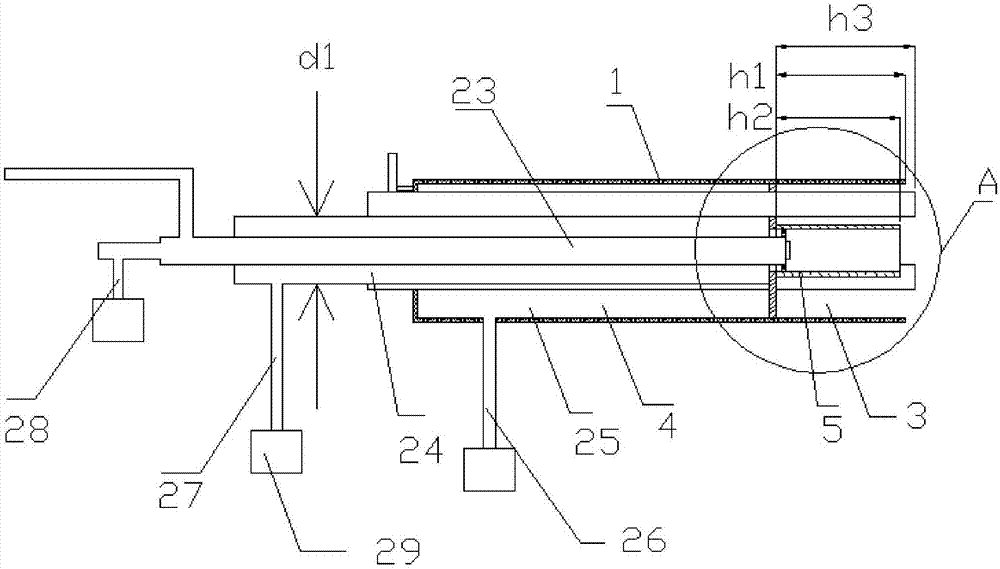

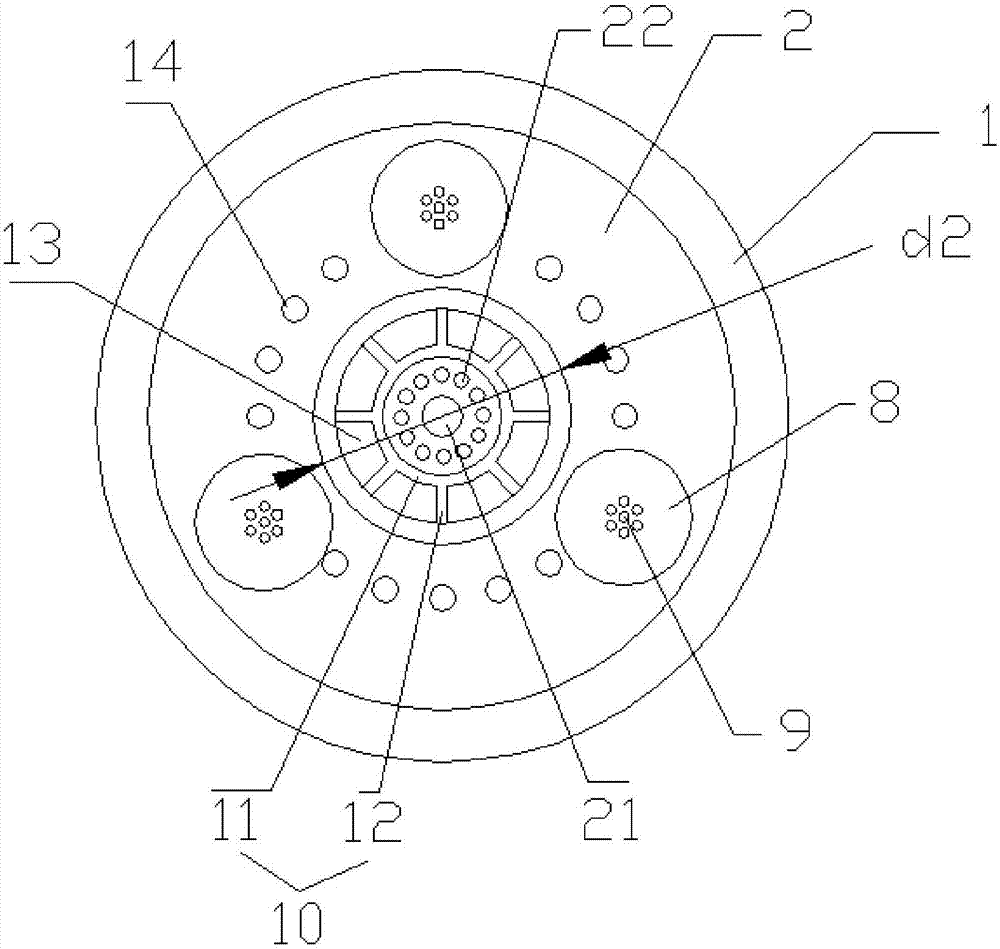

[0025] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for recovering polymerized phosphate by mixed combustion of phosphorus-containing waste. The method comprises the steps that the phosphorus-containing waste and natural gas are directly mixed and burnt through an incineration spray gun; the consumption amount of the phosphorus-containing waste ranges from 1 m<3> / h to 6 m<3> / h, the consumption amount of the natural gas ranges from 50 m<3> / h-500 m<3> / h, and the combustion temperature ranges from 600 DEG C to 850 DEG C; and the phosphorus-containing waste is firstly dried in flames after being atomized, organic matter solid particles are formed and move along with the flame airflow, incineration is continued, organic phosphorus is changed into inorganic phosphate, then the solid density is increased, the particles are precipitated gradually from the flames or the high-temperature airflow, the automatic separation function is achieved, the particles are separated from a high temperature area, and the product melting is reduced.

Description

technical field [0001] The invention relates to a method for recycling phosphorus-containing waste materials, in particular to a method for recovering polymerized phosphate by mixed combustion of phosphorus-containing waste materials. Background technique [0002] Due to the phosphorus-containing waste residues and waste liquids in many industries such as oil refining, chemical industry, medicine and pesticides, according to environmental protection requirements, the discharge of waste residues and waste liquids has strict requirements on phosphorus content, especially for the pesticide industry, phosphorus-containing waste liquids and waste residues are more common. Such as glyphosate, paraquat, acetochlor, acephate, chlorpyrifos, propanil, glufosinate, imidacloprid, chlorimsulfuron, triazophos, malathion and other pesticide industries, and their raw materials or Production of intermediates, such as phosphorus trichloride, phosphorus oxychloride, phosphorous acid, dimethyl ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G7/04

CPCF23G7/04F23G2209/10

Inventor 朱建民詹波叶旭初姜胜宝吕峰王垚刘冰郑新孙洁

Owner ZHENJIANG JIANGNAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com