Steel bar corrosion monitoring method

A steel bar corrosion and steel bar technology, applied in the field of steel bar corrosion monitoring, can solve the problems of loss of life and property safety, reduction of building structure strength, peeling of concrete protective layer, etc., and achieve the effect of simple monitoring, improved sensitivity, and accurate and reliable monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]The steel bar corrosion monitoring method involved in this embodiment is implemented in a parallel resistance type steel bar corrosion monitoring device, and the monitoring process includes two steps of installing a parallel resistance type steel bar corrosion monitoring device and monitoring the steel bar corrosion status:

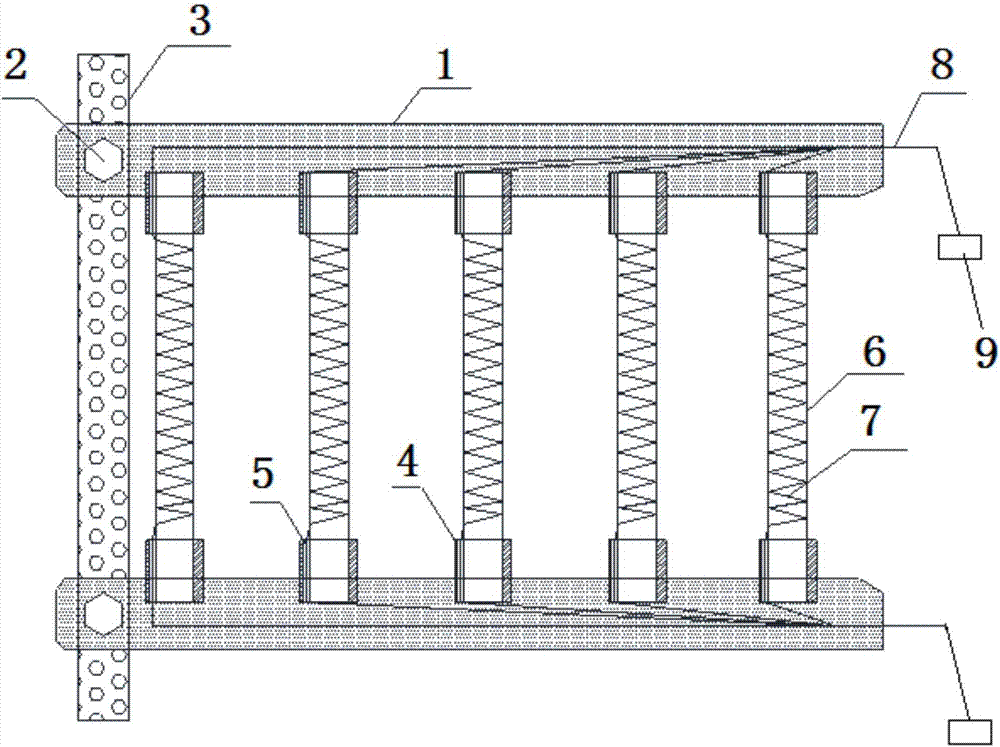

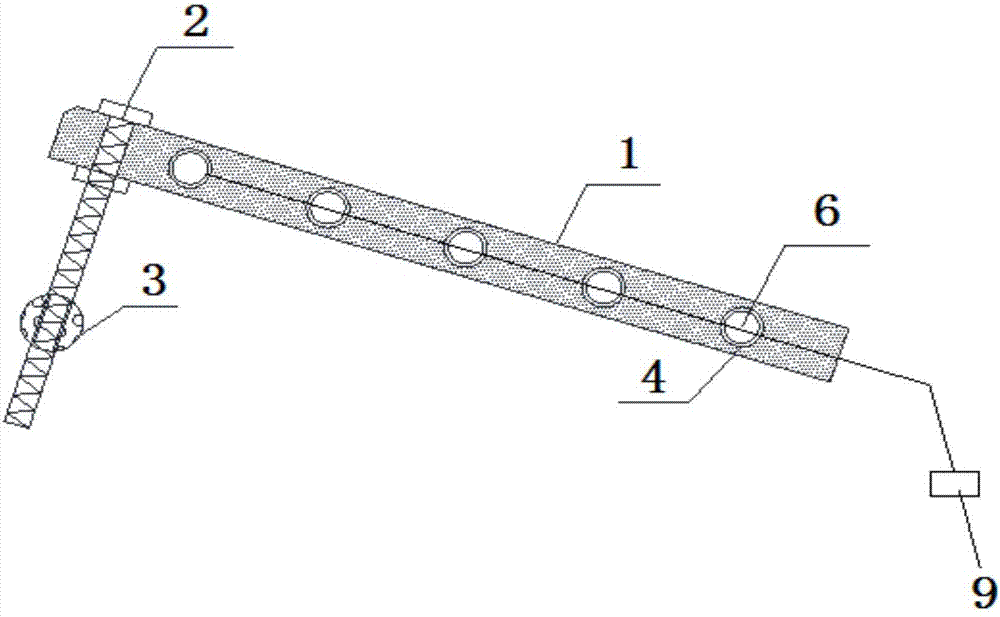

[0031] (1), installation of parallel resistive steel bar corrosion monitoring device: according to the thickness of the concrete cover, adjust the inclination of the parallel resistive steel bar corrosion monitoring device by changing the length of the bolt 2 deep into the fixed bar 3, and connect the fixed bar 3 with the steel bar to be tested Bind together, fix the terminal box connected to the external resistance measuring instrument on the outside of the formwork, and pour concrete;

[0032] (2) Monitoring the corrosion of steel bars: Turn on the resistance measuring instrument. During the monitoring process, the penetration of corrosive substanc...

Embodiment 2

[0046] The steel bar corrosion monitoring method involved in this embodiment is implemented in a parallel resistance type steel bar corrosion monitoring device, and the monitoring process includes two steps of installing a parallel resistance type steel bar corrosion monitoring device and monitoring the steel bar corrosion status:

[0047] (1), installation of parallel resistive steel bar corrosion monitoring device: according to the thickness of the concrete cover, adjust the inclination of the parallel resistive steel bar corrosion monitoring device by changing the length of the bolt 2 deep into the fixed bar 3, and connect the fixed bar 3 with the steel bar to be tested Bind together, fix the terminal box connected to the external resistance measuring instrument on the outside of the formwork, and pour concrete;

[0048] (2), monitoring steel bar corrosion condition: turn on the resistance measuring instrument, in the monitoring process, five steel wires 7 with the same diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com