System for obtaining defect part model of damaged part

A technology of parts and models, which is applied in the system field of obtaining models of damaged parts and defective parts, can solve problems such as huge data volume, low efficiency and accuracy of model reconstruction, and inability to provide damaged parts models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

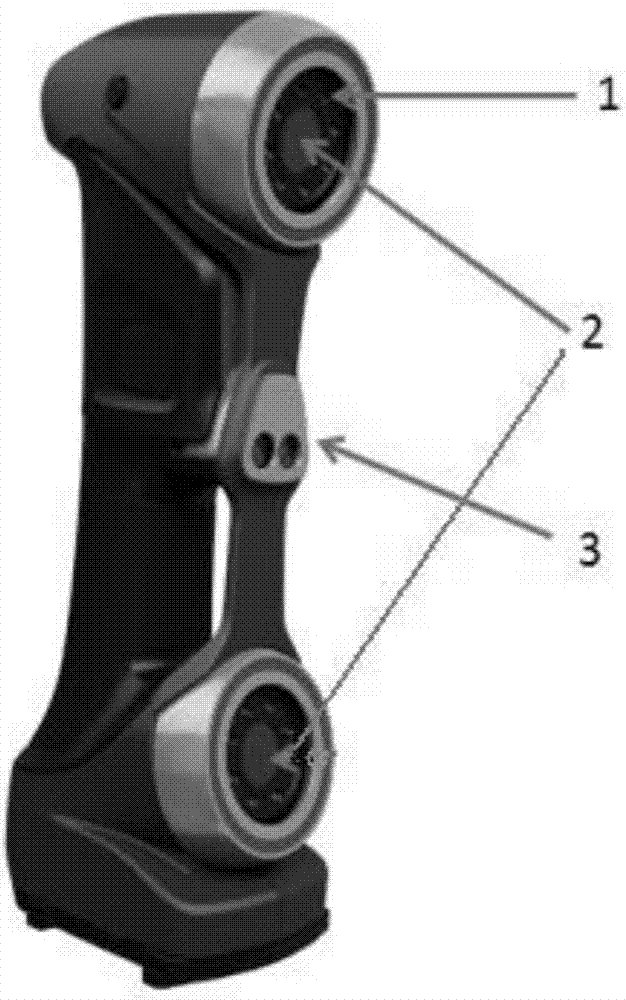

[0073] A kind of system that obtains the defective part model of damaged parts of this embodiment adopts laser triangulation method data test technology, and described hardware system comprises computer and the scanner that is electrically connected with computer; See figure 1 , the scanner includes 2 line lasers 3, 2 CCD cameras 2, image acquisition cards, LED lights 1, control buttons and the housing for placing the aforementioned components; the line lasers 3, CCD cameras 2 and image acquisition The cards are each electrically connected to the computer. Among them, two line lasers 3 are light sources, and each line laser 3 can emit three beams of line lasers to form three beams of intersecting cross laser beams; two CCD cameras 2 are used to capture the deformed grating images of the damaged parts to be collected, and will The target image is converted into an analog electrical signal; the image acquisition card converts the analog electrical signal of the measured target i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com