Vegetable soft capsule composition not comprising chemical metal salts

A technology of chemical metal and soft capsules, applied in the field of vegetable soft capsule compositions that do not contain chemical metal salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

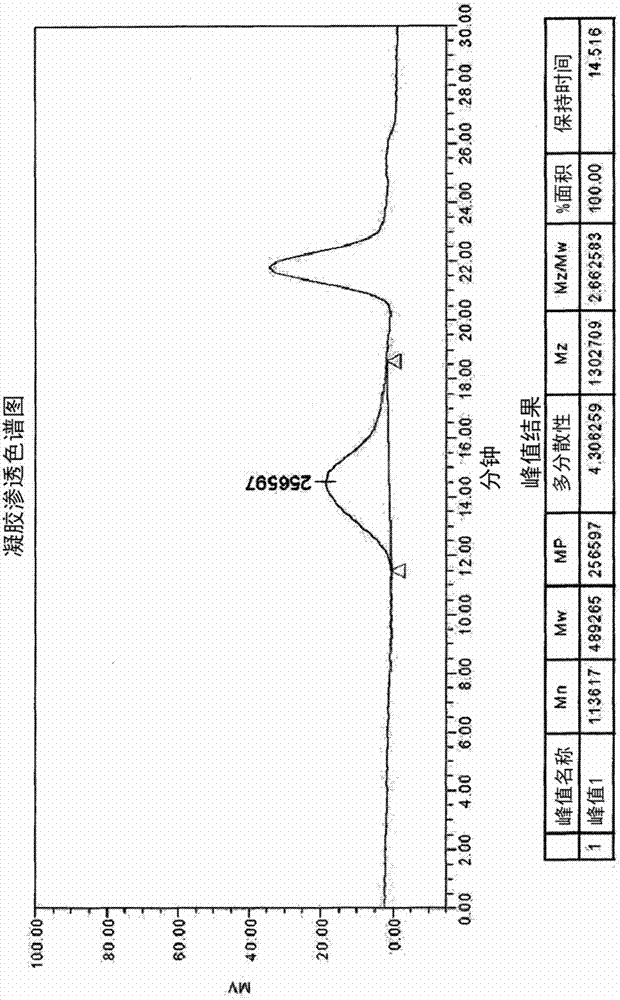

Image

Examples

experiment example 1

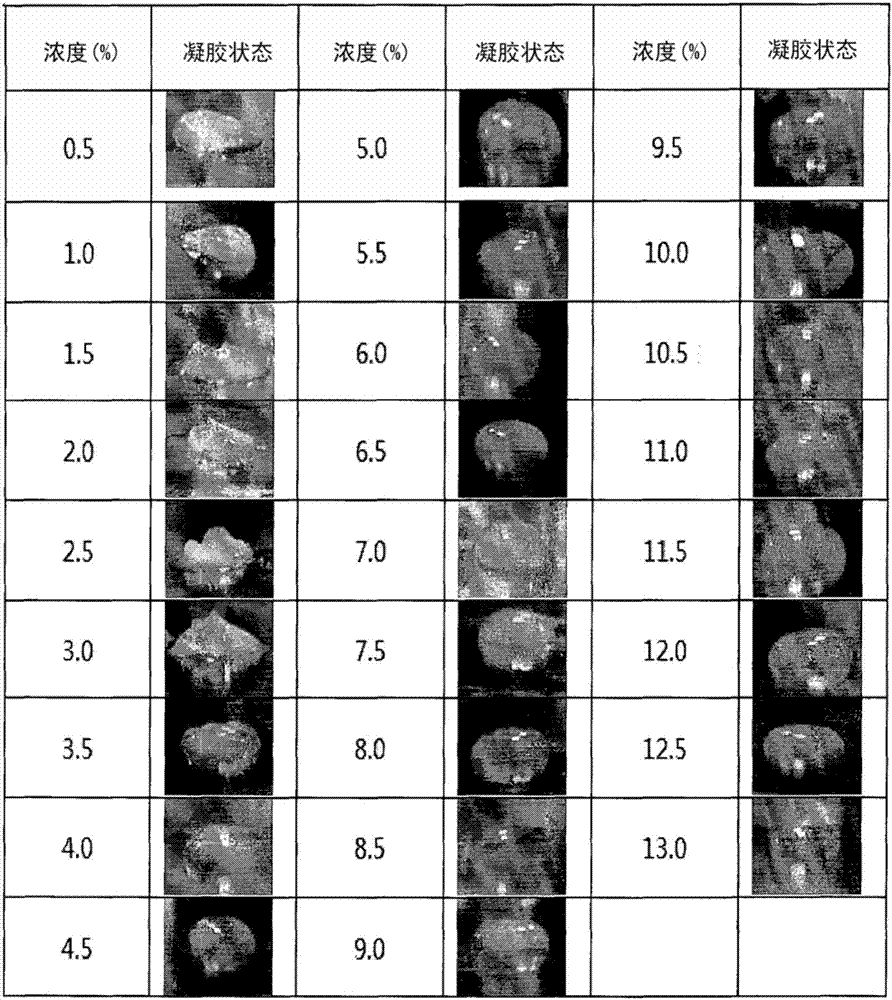

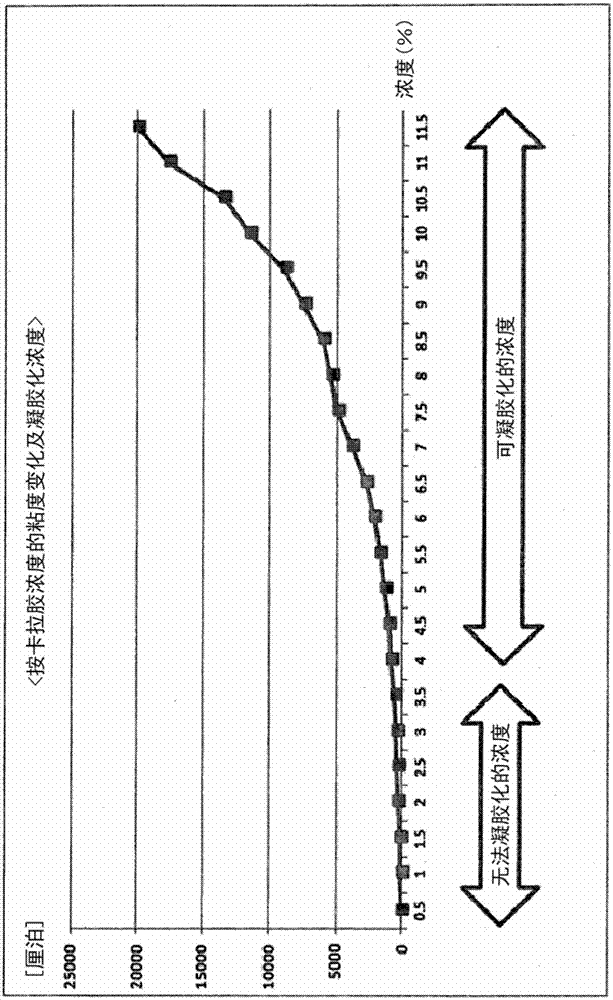

[0060] In order to set the amount of high-purity iota-carrageenan required for the gelation of wet films, after dissolution by concentration, the viscosity and gelation state were confirmed.

[0061] 1) Preparation method: After putting 0.5g of carrageenan into a 250ml beaker, fill it with purified water to prepare 100g, then stir, and raise the temperature to 80°C to completely hydrate. Viscosity and gelation state were confirmed after blending to 0.5 to 13% by weight at intervals of 0.5% by weight by the same method.

[0062] 2) Viscosity measurement method

[0063] (1) Viscometer: Brookfield DV-II+

[0064] (2) Conditions: LV3, LV4 (Spindle), 80°C, 20rpm

[0065] 3) Confirmation method of the gelation state: About 3 g of the hydrated solution was dropped on a stainless steel plate at a temperature of about 10°C. After 10 minutes of curing, when the reagent spoon is pressed about 2 mm and the pressure is released, the gel should not be applied to the spoon and the gel sho...

experiment example 2

[0072] In order to confirm the dissolving properties of the capsules in water after preparing soft capsules, after preparing wet films with varying concentrations of iota-carrageenan, the disintegration state was confirmed by drying. In the case of ordinary gelatin soft capsules, the amount of the powder component (gelatin) is about 40%, but the carrageenan of the present invention shows a sharp viscosity due to low-temperature purified water, so when the stirring motor of the film dissolution tank is considered A suitable amount of powdered ingredients is at the level of about 30% when loaded. After drying, the plasticizer which imparts elasticity to the film uses glycerin as in the gelatin soft capsule, and is set between 15% and 25% by weight, which is an amount generally used. As a solvent, purified water is set at about 45 to 55% by weight. In addition, in order to confirm the influence of the potassium salt and the sodium salt, an experiment was carried out by adding 1%...

experiment example 3

[0082] In order to confirm the compounding amount of iota-carrageenan and the sealing temperature of the soft capsule, a composition of the present invention (Example 3), a composition containing 6% or more of carrageenan (Comparative Example 1) and a sodium salt were prepared, respectively. Composition (comparative example 5), and utilize the soft capsule forming machine of common rotary mold mode to prepare soft capsule, thereby compared the quality of preparation procedure (dissolving time, bonding temperature) and soft capsule (disintegration, bonding rate and burst strength).

[0083] 1) Composition of coating solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com