Compositions for protecting objects from corrosion

一种组合物、物品的技术,应用在包括金属,金属合金,金属组合物和/或混凝土的物品领域,能够解决有限可加工性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] A filler-free mixture was prepared by mixing polyisobutene (Oppanol B10 from BASF), hydrocarbon wax (microcrystalline wax MMP from Shell) and optional antioxidant at high temperature (about 140°C). The composition is shown in Table 1.

[0148] Table 1

[0149]

[0150]

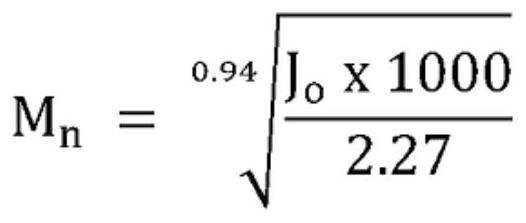

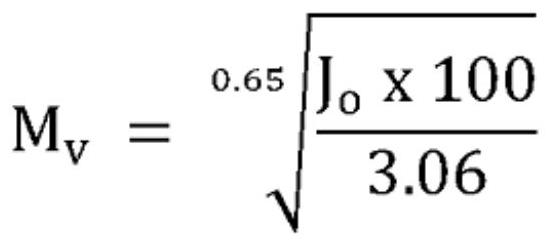

[0151] Oppanol B10 has an M of 40000 v , Staudinger index J 0 =27.5-31.2cm 3 / g, M w =36000, molar mass distribution=3.0, dynamic viscosity at 150°C=40,000, glass transition temperature T g = -65°C (BASF brochure, January 2009 " Type B" (B10 to B15); incorporated by reference).

[0152] According to ASTM D 938 (Product Data Sheet, November 2009; incorporated by reference), Microcrystalline Wax MMP has a freezing point of 70-76°C.

[0153] All mixtures were non-tacky at ambient temperature. All mixtures adhered very well to stainless steel surfaces over a temperature range of -20°C to 65°C. The adhesion strength is similar to that of pure polyisobutylene. All mixtures were still handleab...

Embodiment 2

[0156] The mixture with filler (quartz sand) was prepared by mixing polyisobutylene (Oppanol B10 from BASF), hydrocarbon wax (microcrystalline wax MMP from Shell) and optional antioxidant and high temperature (about 135°C). Compositions are shown in Table 2.

[0157] Table 2

[0158]

[0159]

[0160] All mixtures were non-tacky at ambient temperature. All mixtures adhered very well to stainless steel surfaces over a temperature range of -20°C to 65°C. The adhesion strength is similar to that of pure polyisobutylene. All mixtures were still handleable at -48°C.

[0161] Mixes No. 4 and No. 5 can be treated by spraying at about 55°C.

Embodiment 3

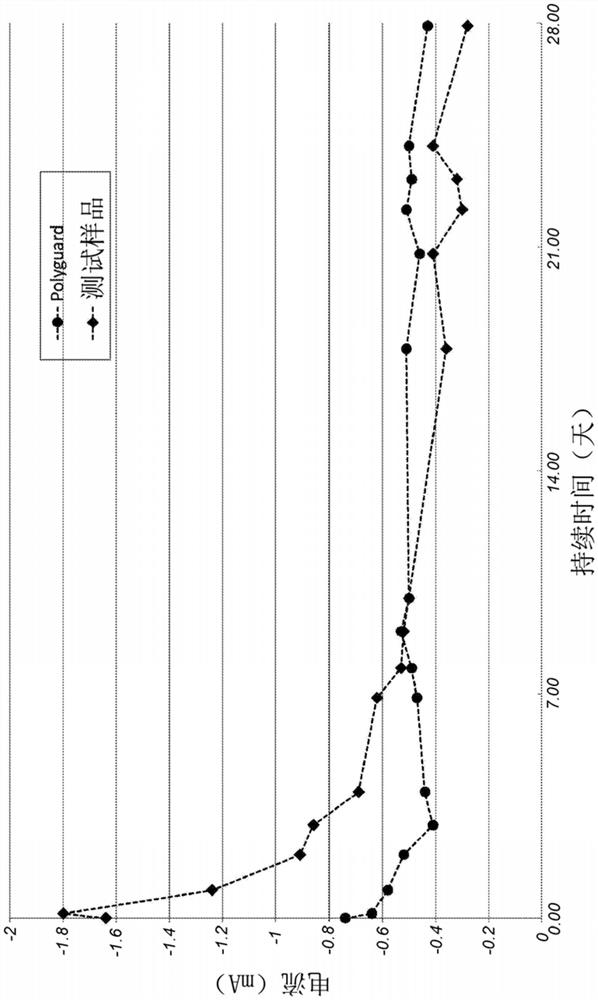

[0163] Cathodic disbondment test

[0164] The cathodic disbondment test is a well known and generally accepted laboratory test for pipeline coatings (see e.g. www.nace.org and E. Broesder, "Coatings and Cathodic Disbondment - The True Story" )”, full paper presented at CEOCOR Annual Meeting, Lucerne (Switzerland), May 2012)).

[0165] In this test, an artificial defect is created in the coating up to the bare steel of the pipeline (the diameter of the defect depends on the standard used). Bare steel in damage is brought into contact with the electrolyte by attaching a battery containing the electrolyte to the defect. An inert counter electrode (anode) and reference electrode are also immersed in the electrolyte. Connect the test sample and counter electrode to a power source. Turn on the power and adjust until the potential measured between the reference electrode and the test sample reaches the desired value. The applied potential must be frequently adjusted, and the curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com