Preparation method for hydrothermal carbon-based sustained-release nitrogenous fertilizer

A technology of hydrothermal carbonization and hydrothermal carbonization, which is applied in the direction of nitrogen fertilizer, fertilization equipment, ammonium nitrate fertilizer, etc., and can solve problems such as disharmony, crop straw burning, and low soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

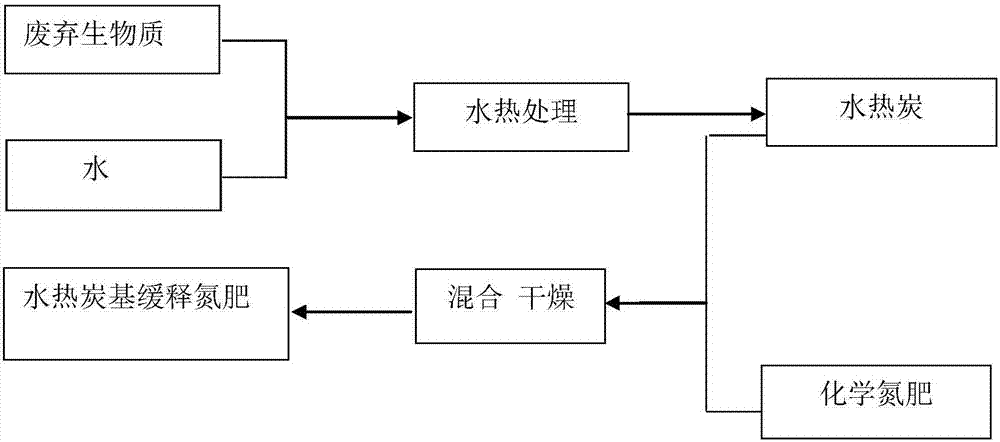

Method used

Image

Examples

Embodiment 1

[0022] 1. Material preparation

[0023] The pig manure was dried and crushed to less than 5mm, and set aside. Soil value Garden of Eco-Environmental Research Center, Chinese Academy of Sciences (organic matter 15.36g / kg; CEC 7.9cmol / kg; TN 0.80g / kg; TK 20.32g / kg; TP 0.99g / kg;)

[0024] 2. Preparation of slow-release nitrogen fertilizer

[0025] 1) Mix pig manure (dry basis) with water at a ratio of 1:5 and put it into a hydrothermal reactor.

[0026] 2) Heating the reactor to 200°C and maintaining it for 60 minutes; then cooling by an electric fan and internal circulating cooling water, and then performing solid-liquid centrifugation to obtain hydrothermal charcoal;

[0027] 3) Ammonium nitrate solid is mixed with hydrothermal charcoal (hydrothermal charcoal and ammonium nitrate are mixed according to the ratio of 4:1);

[0028] 4) After mechanical stirring for 2 hours, dry in a blast dryer at 60° C. to obtain the hydrothermal charcoal-based slow-release nitrogen fertilizer...

Embodiment 2

[0047] In addition to using corn stover instead of pig manure.

[0048] In the preparation step 2) of the hydrothermal charcoal-based slow-release nitrogen fertilizer, except for the treatment at 220° C. for 80 minutes, the rest is the same as in Example 1.

[0049] The analysis results are shown in Table 1 and Table 2.

Embodiment 3

[0051] In addition to replacing pig manure with rice straw.

[0052] In the preparation steps of hydrothermal charcoal-based slow-release nitrogen fertilizer, 1) mix rice straw (dry basis) with water at a ratio of 1:5;

[0053] The analysis results are shown in Table 1 and Table 2.

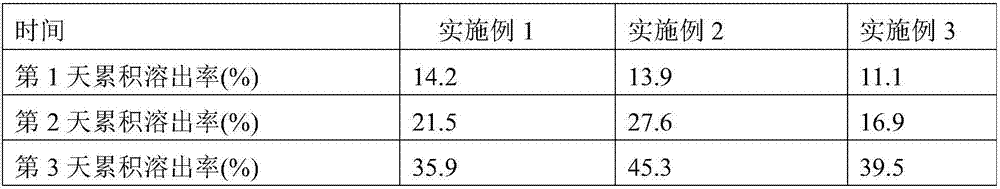

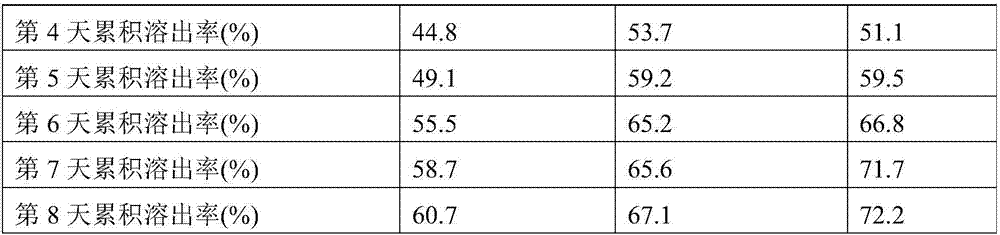

[0054] Table 1. Cumulative dissolution rate of hydrothermal carbon-based slow-release nitrogen fertilizer aqueous solution.

[0055]

[0056]

[0057] Table 2. Cumulative leaching rate of nitrogen leached from hydrothermal charcoal-based slow-release nitrogen fertilizer soil column.

[0058] time ammonium nitrate Example 1 Example 2 Example 3 Cumulative dissolution rate on the second day (%) 82.7 16.2 15.2 16.8 Cumulative dissolution rate on the 4th day (%) 83.6 41.5 51.8 38.4 Cumulative dissolution rate on the 6th day (%) 84.5 59.6 62.2 55.5 Cumulative dissolution rate on the 8th day (%) 87.9 60.8 69.1 59.6 Cumulative dissolution rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com