Modification method for in situ polymerization of pyrrole on surfaces of carbon fibers

An in-situ polymerization and modification method technology, applied in the direction of carbon fiber, fiber treatment, chemical instruments and methods, etc., can solve the problems of no further performance improvement, achieve strong adsorption characteristics, good biocompatibility, and avoid eutrophication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

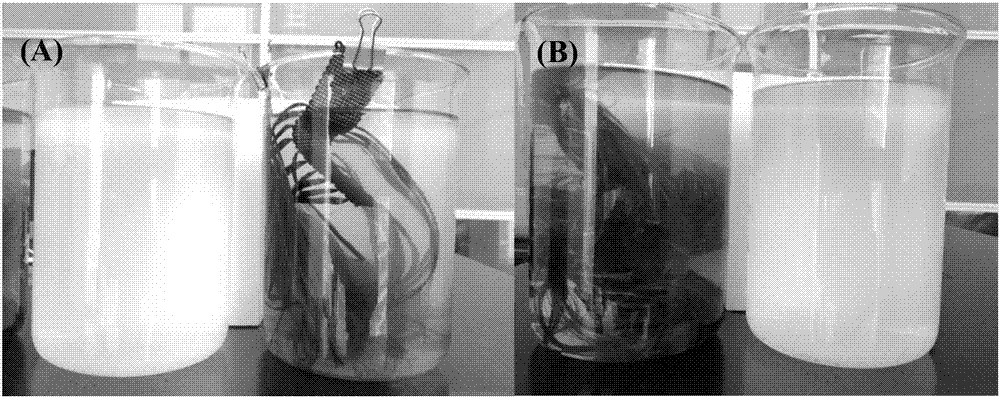

Embodiment 1

[0030] Add 3L of deionized water into a 5L glass container, add 10g of pyrrole monomer, disperse it after stirring, and control the temperature at 4°C with a water bath, then place 1000.0g of the woven carbon fiber in the glass container and let it stand for 2h. Then add 1mol / L FeCl 3 Solution 348mL, fully stirred and kept for 24h, so that the reaction is complete. Then use 5M NaOH to adjust the pH value of the reaction solution to 7.0, remove the reaction solution, add water to rinse once; then take out the fibers, drain the water and bake in an oven at 105°C overnight until constant weight, then weigh with a balance The total weight of the obtained fibers was 1008.6 g, which indicated that most of the pyrrole had polymerized on the surface of the fibers.

Embodiment 2

[0032] Add 3L of deionized water into a 5L glass container, add 20g of pyrrole monomer, disperse it after stirring, and control the temperature at 4°C with a water bath, then place 1000.0g of the woven carbon fiber in the glass container and let it stand for 2h. Then add 0.5mol / L of (NH 4 ) 2 S 2 o 8 Solution 348mL, fully stirred and kept for 24h, so that the reaction is complete. Then use 5M NaOH to adjust the pH value of the reaction solution to 7.0, remove the reaction solution, add water to rinse once; then take out the fibers, drain the water and bake in an oven at 105°C overnight until constant weight, then weigh with a balance The total weight of the obtained fiber was 1018.6 g, which indicated that most of the pyrrole had been polymerized on the surface of the fiber, and the in-situ polymerization of pyrrole was successful.

Embodiment 3

[0034] Add 0.2L of deionized water into a 5L glass container, add 10g of pyrrole monomer, disperse it after stirring, and control the temperature at 60°C with a water bath, then place 20.0g of the woven carbon fiber in the glass container and let it stand for 0.5h . Then add 1mol / L FeCl 3 solution, FeCl 3 FeCl in solution 3 The molar ratio to pyrrole monomer is 1:1; fully stir and keep warm for 48h to complete the reaction. Then use 5M NaOH to adjust the pH value of the reaction solution to 7.0, remove the reaction solution, add water to rinse once; then take out the fibers, drain the water and bake in an oven at 105°C overnight until constant weight, then weigh with a balance The resulting fiber had a total weight of 28.8 g, which indicated that most of the pyrrole had polymerized on the surface of the fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com