Environment-friendly inorganic wide-wave far infrared composite material

An environmentally friendly material and far-infrared technology, applied in the field of far-infrared composite materials, can solve problems such as large functional limitations, single material, and narrow far-infrared band, and achieve the effects of low cost, wide application, and wide band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

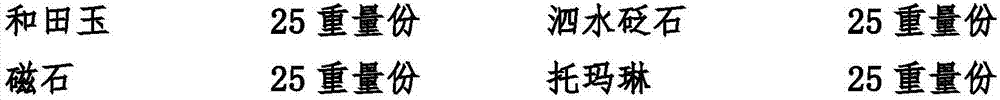

Embodiment 1

[0043] Take 100 kg each of Hetian jade, Sishui Bian stone, magnetite, and tourmaline, and use a collider to crush them to 6000 mesh, then mix them, add an appropriate amount of water and stir evenly, press them into a ball with a diameter of 0.5 cm, and calcinate at 1000 °C After 24 hours, after cooling at room temperature, put it in water. After 2 hours, the pH value was detected to be 7.8, the chlorine was 0, and the mineral content increased by 10%.

Embodiment 2

[0045] Hetian jade, Surabaya meteorite, magnetite, and tourmaline are each 5 kg, respectively crushed to 6000 mesh with a collider, then mixed and calcined at 1000 degrees for 24 hours; after crushing again to 6000 mesh, add medical desensitizing glue and stir evenly , Spray on both sides of the blades of the vertical fan. The fan works in summer, and the indoor air has 1,000 negative oxygen ions per cubic centimeter, making the air fresh.

Embodiment 3

[0047] Hetian jade, Surabaya meteorite, magnetite, and tourmaline are 50 kg each, crushed to 6000 mesh with a collider, then mixed, added an appropriate amount of water and stirred evenly, pressed into a cylinder with a diameter of 0.5 cm and a height of 0.5 cm, 1000 ° C Calcined for 24 hours and cooled at room temperature. Sprinkle it evenly in the vegetable field, and after three months, the soil pesticide residues and lead, cadmium, mercury, and arsenic will be zero, the soil will restore the original ecology, and the vegetable yield will increase by 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com