Gene recombination trypsin cell dissociation solution

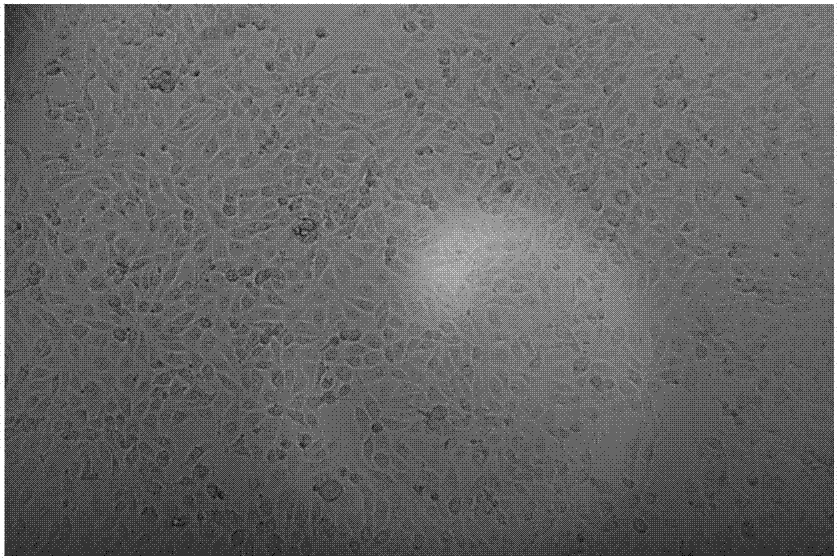

A technology of gene recombination and trypsin, applied in cell culture medium, tissue culture, biochemical equipment and methods, etc., can solve the problems of complex composition and donor contamination, and achieve high cell viability, stable quality and good growth state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

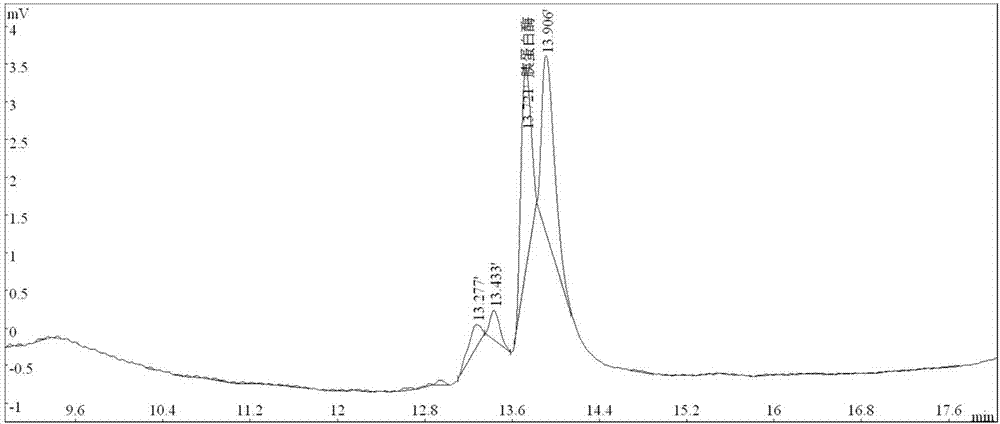

[0028] Example 1 Preparation of Gene Recombinant Trypsin Cell Digestion Solution

[0029] It is composed of components with the following concentrations, each concentration unit is mg / L: dipotassium hydrogen phosphate 60, potassium chloride 400, sodium bicarbonate 350, sodium chloride 8000, disodium hydrogen phosphate heptahydrate 90, glucose 1500, EDTA-4Na350, gene recombinant trypsin 30, the balance is water.

[0030] The preparation method is as follows: take the above-mentioned components except water, classify and dissolve them according to their respective solubility characteristics, then mix them, add water to make the final concentration of each component as above, adjust the pH value to 7.2-7.4, that is, filter with industrial filter element , At the same time, nitrogen protection is carried out for sub-packaging (to avoid oxidation of unstable components).

Embodiment 2

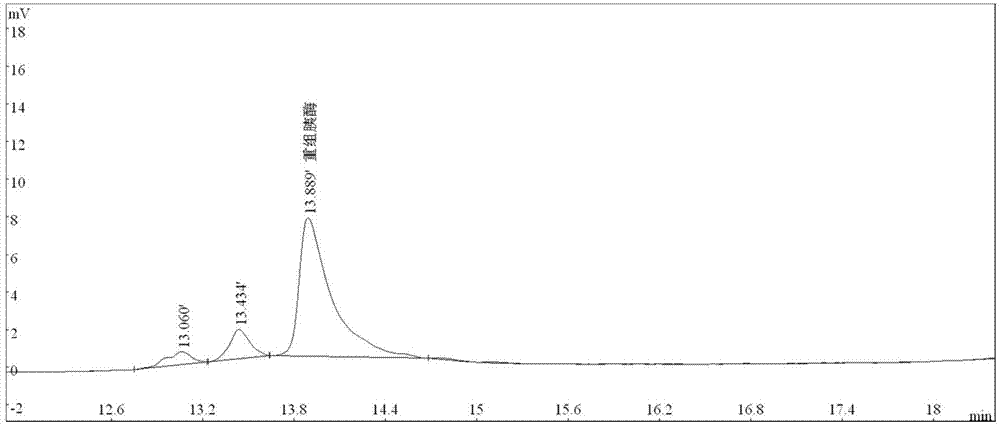

[0031] Example 2 Preparation of Gene Recombinant Trypsin Cell Digestion Solution

[0032] It is composed of components with the following concentrations, and the units of each concentration are mg / L: dipotassium hydrogen phosphate 50, potassium chloride 450, sodium bicarbonate 300, sodium chloride 9000, disodium hydrogen phosphate heptahydrate 80, glucose 2000, EDTA-4Na500, gene recombinant trypsin 10, the balance is water.

[0033] The preparation method is as follows: take the above-mentioned components except water, classify and dissolve them according to their respective solubility characteristics, then mix them, add water to make the final concentration of each component as above, adjust the pH value to 7.2-7.4, that is, filter with industrial filter element , At the same time, nitrogen protection is carried out for sub-packaging (to avoid oxidation of unstable components).

Embodiment 3

[0034] Example 3 Preparation of Gene Recombinant Trypsin Cell Digestion Solution

[0035] It is composed of components with the following concentrations, each concentration unit is mg / L: dipotassium hydrogen phosphate 70, potassium chloride 350, sodium bicarbonate 400, sodium chloride 7000, disodium hydrogen phosphate heptahydrate 100, glucose 2000, EDTA-4Na200, genetic recombinant trypsin 50, the balance is water.

[0036] The preparation method is as follows: take the above-mentioned components except water, classify and dissolve them according to their respective solubility characteristics, then mix them, add water to make the final concentration of each component as above, adjust the pH value to 7.2-7.4, that is, filter with industrial filter element , At the same time, nitrogen protection is carried out for sub-packaging (to avoid oxidation of unstable components).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com