Yarn self-cleaning size, self-cleaning yarn and preparation method thereof

A self-cleaning slurry and self-cleaning technology, which is applied in the field of yarn processing, can solve the problems of easy contamination of yarn and difficult cleaning of fabrics, and achieve the effects of improving adsorption fastness, improving mechanical properties, and being easy to clean

Active Publication Date: 2019-11-19

湖南莎丽袜业股份有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] For example, traditional yarns are easily stained with dirt, which makes it difficult to clean the woven fabric and brings a lot of inconvenience to users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

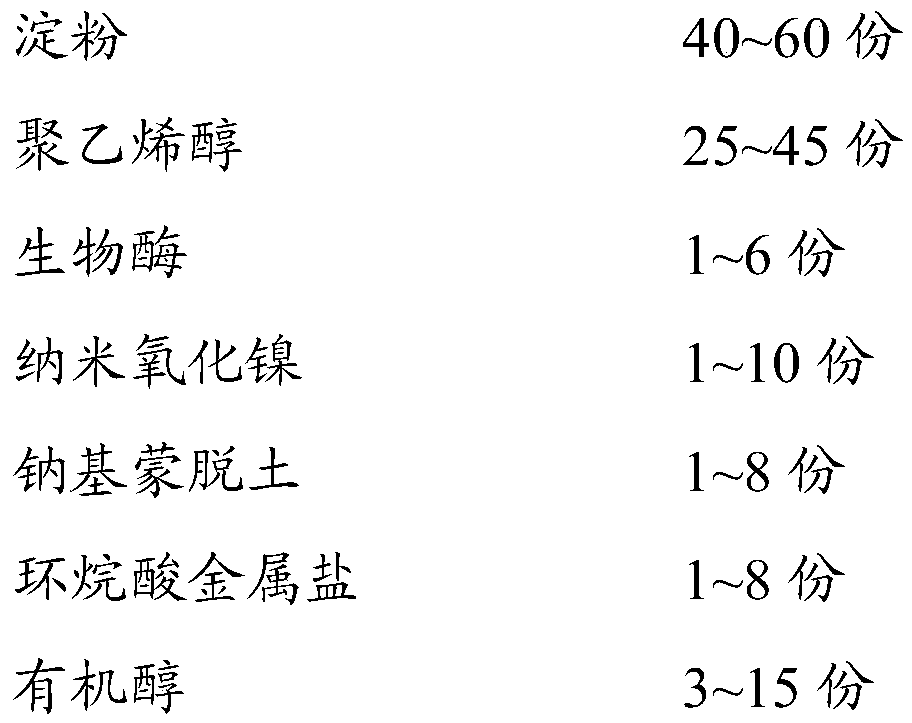

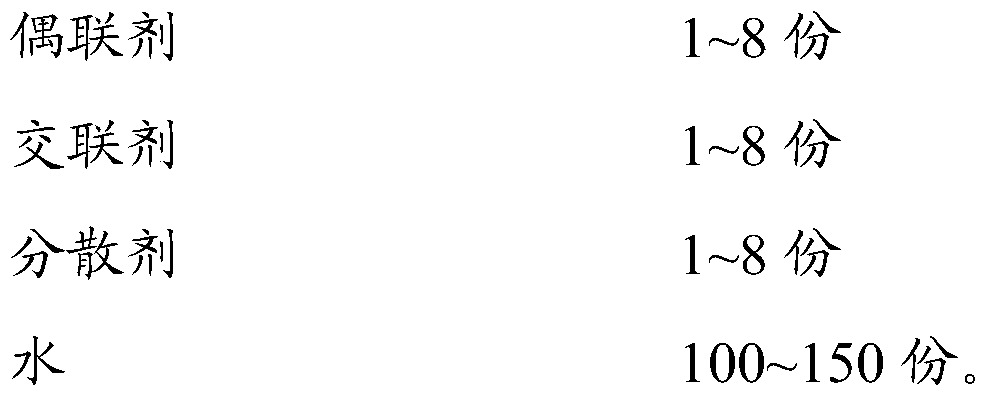

[0044] Weigh and mix the components according to the parts by weight in Table 1, heat at 80°C for 60 minutes to obtain the yarn self-cleaning slurry, immerse the yarn in the yarn self-cleaning slurry, then extrude and dry to obtain Self-cleaning yarn.

[0045] Table 1

[0046]

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a self-cleaning size for yarns, a self-cleaning yarn and a preparation method thereof. The self-cleaning size for yarns is prepared from the following components in parts by weight: 40 to 60 parts of starch, 25 to 45 parts of polyvinyl alcohol, 1 to 6 parts of biological enzyme, 1 to 10 parts of nano-nickel oxide, 1 to 8 parts of Na-montmorillonite, 1 to 8 parts of metal naphthenate, 3 to 15 parts of organic alcohol, 1 to 8 parts of coupling agent, 1 to 8 parts of cross-linking agent, 1 to 8 parts of dispersant and 100 to 150 parts of water. The self-cleaning size for yarns disclosed by the invention can ensure that highly complex multiple nanoscale and micron-scale ultramicrostructures are formed on the surface of a yarn, consequently, a lotus effect is generated, and the yarn obtains a self-cleaning characteristic like a lotus leaf; moreover, under the effect of light, the self-cleaning size for yarns can generate a strong catalytic degradation function, consequently, odor can be effectively removed, staining can be effectively resisted, a variety of bacteria and fungi can be killed, and the yarn cannot be easily stained, and is easy to clean. The size has good adhesion to the yarn, the polyvinyl alcohol is highly compatible to the starch, furthermore, the flexibility of a size film can be enhanced, and the mechanical property of the yarn can be increased.

Description

technical field [0001] The invention relates to the field of yarn processing, in particular to a yarn self-cleaning slurry, a self-cleaning yarn and a preparation method thereof. Background technique [0002] Yarn is a soft and slender fiber aggregate with certain mechanical properties formed by the aggregation of textile fibers along the length direction. According to the structure and shape, it includes filament yarn, spun yarn and special yarn. According to the types of fibers that make up the yarn, it includes pure spinning yarn, blended yarn, polyester / cotton yarn (T / C yarn), CVC yarn, etc. At present, the yarn is treated with sizing to increase its strength, that is, yarn sizing is a key link in the weaving process. The purpose of sizing is mainly to improve the wear resistance of the yarn, reduce hairiness, and appropriately increase the strength of the yarn. Reduce the elongation to withstand the mechanical force on the warp yarn during the weaving process and impr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M15/11D06M15/333D06M16/00D06M11/49D06M11/79D06M13/188D06M13/144

CPCD06M11/49D06M11/79D06M13/144D06M13/188D06M15/11D06M15/333D06M16/003D06M2200/01D06M2200/11D06M2200/12D06M2200/40

Inventor 董艺林晓洁赵玉萍

Owner 湖南莎丽袜业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com