Preparation method for functional Ganoderma lucidum fermented feed

A technology of Ganoderma lucidum fermentation and manufacturing method, applied in animal feed, animal feed, application, etc., can solve the problems of low feed utilization rate and high mortality rate, improve meat quality, regulate intestinal flora, and solve anti-nutritional factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1-seed culture solution preparation

[0028] Mix 1 part of shrimp shell powder, 3.5 parts of corn flour, 0.5 part of soybean meal, 1.3 part of rice bran, 0.7 part of orange peel powder and / or orange peel powder with cold water, then heat, sterilize at 121°C for 30 minutes, and cool To 30°C, inoculate 5 parts of Ganoderma lucidum under aseptic conditions, and cultivate for 7 days at a rotation speed of 200 rpm and a culture temperature of 30°C to obtain a culture solution of Ganoderma lucidum seeds; the biomass is greater than 1.35 parts.

Embodiment 2

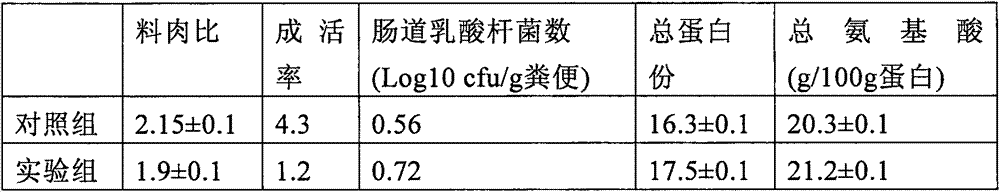

[0029] Embodiment 2-Ganoderma lucidum fermentation 1

[0030] Stir evenly according to the ratio of 40 parts of corn flour, 10 parts of soybean meal, 35 parts of rice bran, 10 parts of shrimp shell powder, and 5 parts of orange peel powder and / or orange peel powder to obtain a solid-state fermented material. Mix evenly at a ratio of 1:1 to obtain a solid-state fermentation medium; insert 10 parts of ganoderma seed liquid into the inoculum, mix evenly, put it into a fermenter, and ferment at 25°C for 14 days to obtain a ganoderma fermentation material; then raise the temperature to 45°C, After heat preservation for 5 hours, a full-priced Ganoderma lucidum fermented feed was obtained; after being dried at 90° C. and crushed, granular Ganoderma lucidum fermented feed was obtained. After inspection, the parts by weight of each functional component are shown in Table 1.

[0031] Functional component parts by weight (parts) in table 1 Ganoderma lucidum fermented feed

[0032] ...

Embodiment 3

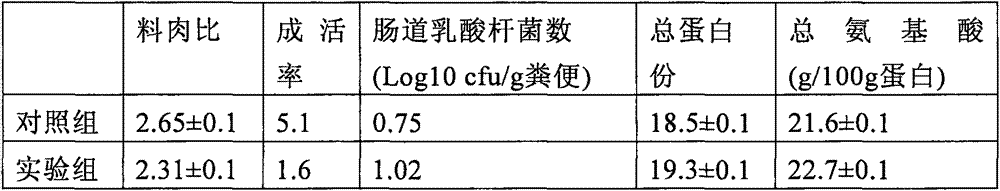

[0033] Embodiment 3-Ganoderma lucidum fermentation 2

[0034] Stir evenly according to the ratio of 35 parts of corn flour, 15 parts of soybean meal, 25 parts of bran, 15 parts of shrimp shell powder, and 10 parts of orange peel powder to obtain a solid-state fermentation material, which is mixed with 80°C water at a ratio of 1:1.2 Uniformly, to obtain a solid-state fermentation medium; add 15 parts of the inoculum to the ganoderma lucidum seed solution, mix it evenly, put it into a fermenter, and ferment it at 30°C for 10 days to obtain a ganoderma lucidum fermentation material; then raise the temperature to 55°C, heat preservation for 8 hours, A full-price Ganoderma lucidum fermented feed is obtained; a granular Ganoderma lucidum fermented feed is obtained after being dried at 90° C. and crushed. After inspection, the parts by weight of each functional component are shown in Table 2.

[0035] Functional component parts by weight (parts) in the ganoderma lucidum fermented fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com