Ultra-low-temperature-resistant halogen-free flame-retardant glass fiber reinforced hard polyurethane thermal insulation material produced from environment-friendly foaming agent, and preparation method thereof

A technology of rigid polyurethane and thermal insulation materials, applied in the field of polyurethane composite materials, can solve the problems of falling flame retardant grade, inability to use thermal insulation, and no detailed thermal conductivity for thermal insulation performance, and achieve high permanent flame retardancy and high size. Stable, high-strength effect

Inactive Publication Date: 2017-08-29

JIANGSU YOKE TECH

View PDF11 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Patent CN101235128A discloses a continuous fiber reinforced fiber with a density of 400-800kg / m 3 Polyurethane foam material, but the material is suitable for "load-bearing structural material" and cannot be used for insulation in ultra-low temperature environments

Patent CN101191010A discloses a continuous fiber reinforced polyurethane foam material, but the material cannot be used as an ultra-low temperature insulation material

Patent CN1834130A discloses a kind of density in 115-135kg / m 3 Insulation materials with a compressive strength of 1.4-1.7MPa, but the patent does not give a detailed thermal conductivity coefficient for the insulation performance of the material, and the flame retardant used in the patent is a small molecule added flame retardant, which migrates out of the bulk material over time It is impossible to guarantee that the material will maintain a high flame-retardant grade for a long time; patent CN101781395A discloses a density of 40-80kg / m 3 However, the patent does not mention the mechanical properties of the material at ultra-low temperatures, and the flame retardant used in the patent is also a small molecular compound, and there is also the possibility that the flame retardant migration will lead to a decrease in the flame retardant grade of the material. possible

Patent CN 103382263 discloses a method for producing polyurethane rigid foam with an environmentally friendly foaming agent. This method can overcome the problem of unstable storage of premixed materials and will not limit the use of catalysts. However, the patent involves The product is used at room temperature with a density of 50kg / m 3 The following polyurethane rigid foam materials

[0003] In summary, there is no report of a polyurethane insulation material that uses an environmentally friendly foaming agent to maintain high strength and permanent flame retardancy under ultra-low temperature conditions (-170 degrees)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

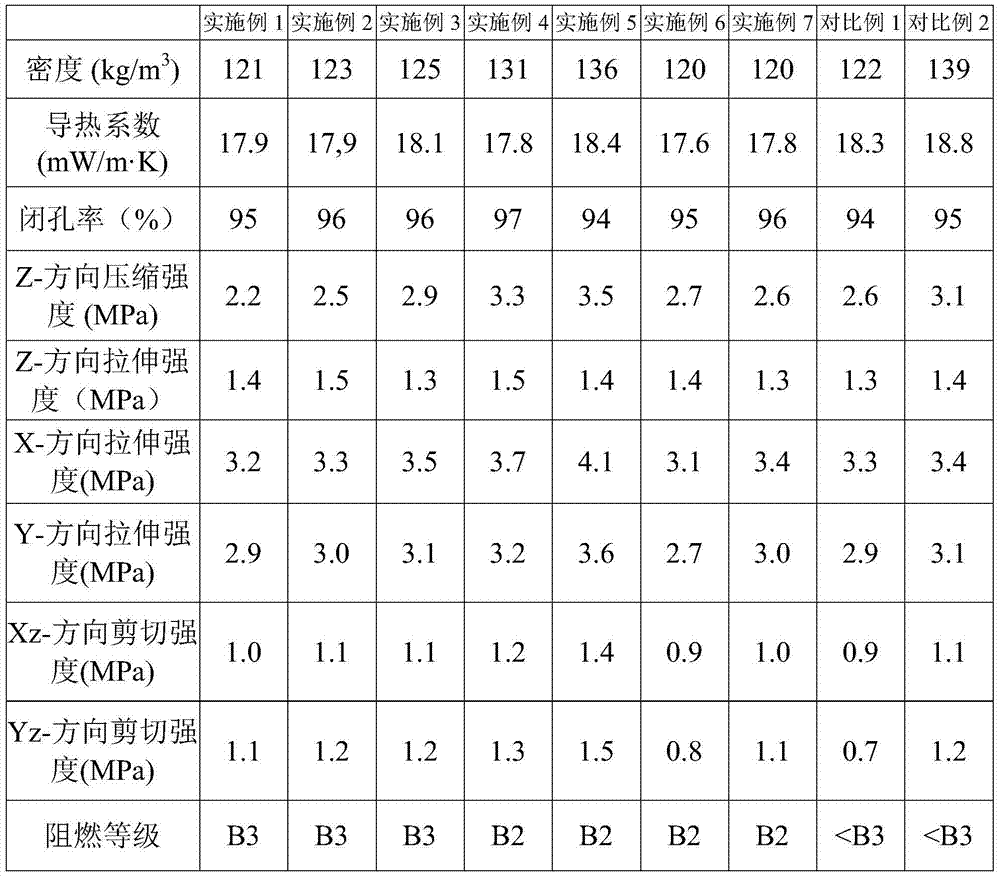

Embodiment 1-7 and comparative example 1-2

[0042] According to the components and contents in Table 1 below, Examples 1-7 and Comparative Examples 1-2 were carried out respectively.

[0043] The raw material mass fraction ratio of table 1, embodiment 1-7 and comparative example 1-2

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

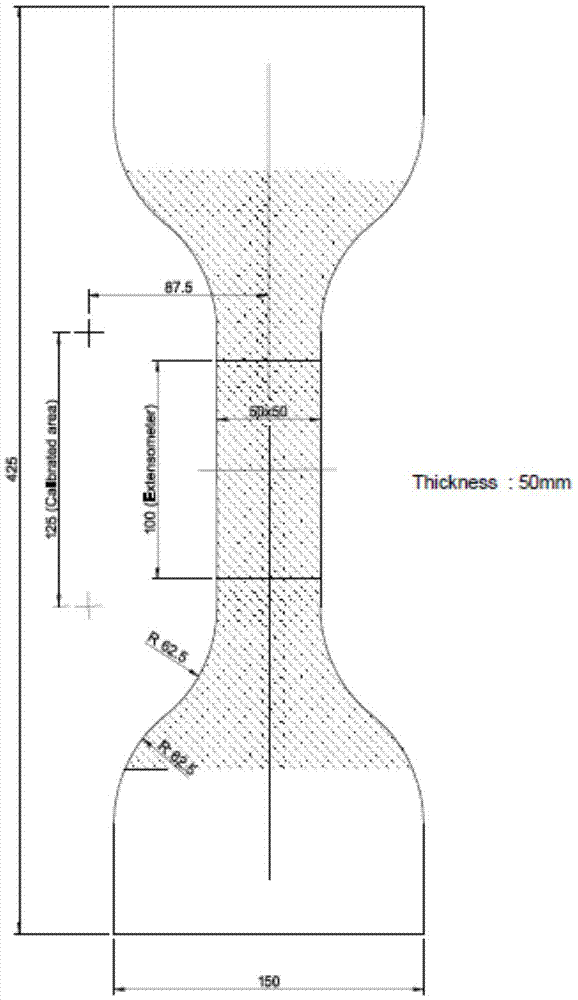

The invention discloses an ultra-low-temperature-resistant halogen-free flame-retardant glass fiber reinforced hard polyurethane thermal insulation material produced from an environment-friendly foaming agent, and a preparation method thereof, wherein the ultra-low-temperature-resistant halogen-free flame-retardant glass fiber reinforced hard polyurethane thermal insulation material comprises reaction type halogen-free flame-retardant polyether polyol, ordinary hard foam polyether, polymethylene polyphenyl polyisocyanate, a 1,6 hexamethylene diisocyanate trimer, a continuous glass fiber felt with the surface treated with a coupling agent, an environmentally friendly physical foaming agent, a surfactant, and a compound delay catalyst. According to the present invention, by using the HFO type fourth-generation environmental-protection foaming agent and the halogen-free reaction type flame-retardant polyether, the prepared material can be used in the -173 DEG C ultra-low temperature environment, and has the product density of 120-140 kg / m<3>, wherein under the condition of -173 DEG C, the thermal conductivity of the product is less than 18 mw / m.K, the porosity is more than 95%, the Z direction compressive strength is greater than 2.7 MPa, the Z- direction tensile strength is more than 1.3 MPa, the X direction tensile strength and the Y direction tensile strength are greater than 2.8 MPa, the Xz direction shear strength and the Yz direction shear strength are greater than 1 MPa, and the flame retardant performance can achieve the B2 standard of GB8624-2012.

Description

technical field [0001] The invention belongs to the technical field of polyurethane composite materials, and in particular relates to a high flame-retardant glass fiber reinforced rigid polyurethane ultra-low temperature thermal insulation material and a preparation method thereof. Background technique [0002] Liquefied natural gas is recognized as the cleanest energy source. With my country's increasing emphasis on environmental protection, the demand for liquefied natural gas is increasing rapidly. The storage and transportation of liquefied natural gas requires the use of thermal insulation materials that maintain high thermal insulation, high strength and high stability in ultra-low temperature environments. Ordinary polyurethane material has excellent thermal insulation performance, but it will shrink severely at ultra-low temperature and cannot maintain its mechanical strength at room temperature. In addition, since polyurethane is a flammable material, welding opera...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G18/79C08G18/48C08J9/14C08K7/14

CPCC08G18/4816C08G18/792C08J9/146C08J2203/162C08J2203/182C08J2375/08C08K7/14C08G2110/0025

Inventor 沈琦曹恒朱红飞居世宝

Owner JIANGSU YOKE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com