Production technology of ginger-garlic seasoning oil

A production process and seasoning oil technology, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of no production process of ginger garlic seasoning oil, etc., and achieve simple structure, large heat transfer area, and energy saving condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] refer to Figure 1-3 , the preparation technology of ginger garlic seasoning oil of the present invention, comprises the following steps:

[0035] Step 1. Selected fresh ginger is put into a pulverizer and crushed into uniform powder with a particle size of 0.2-0.5 mm.

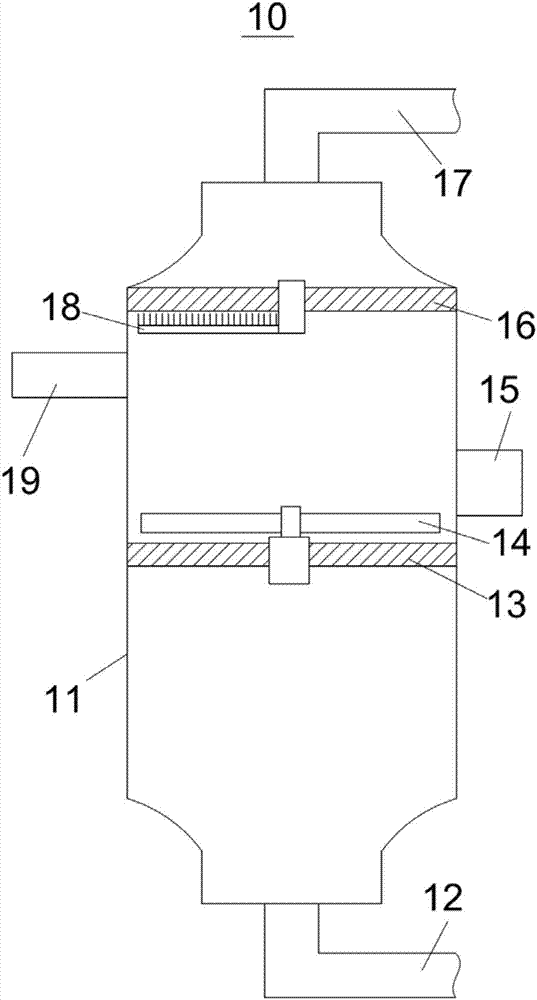

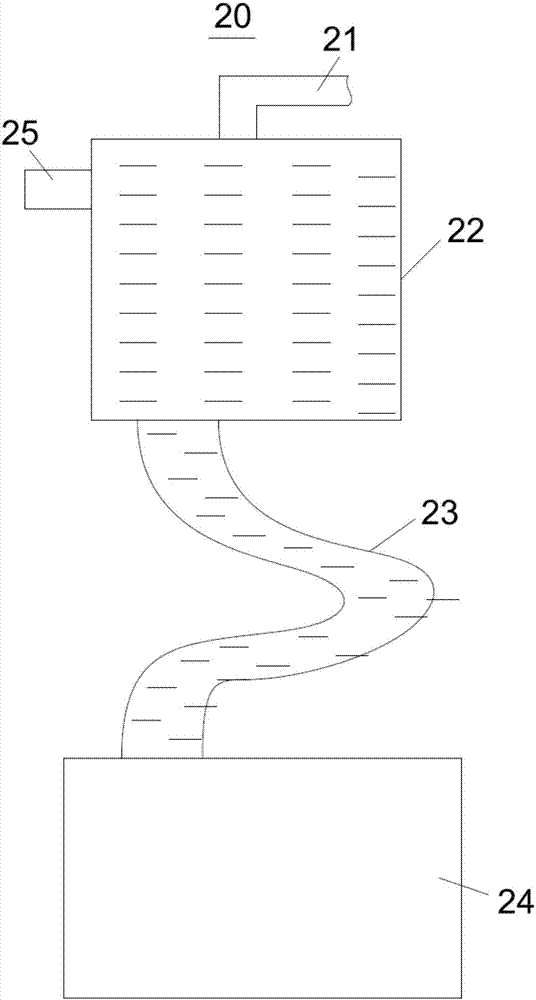

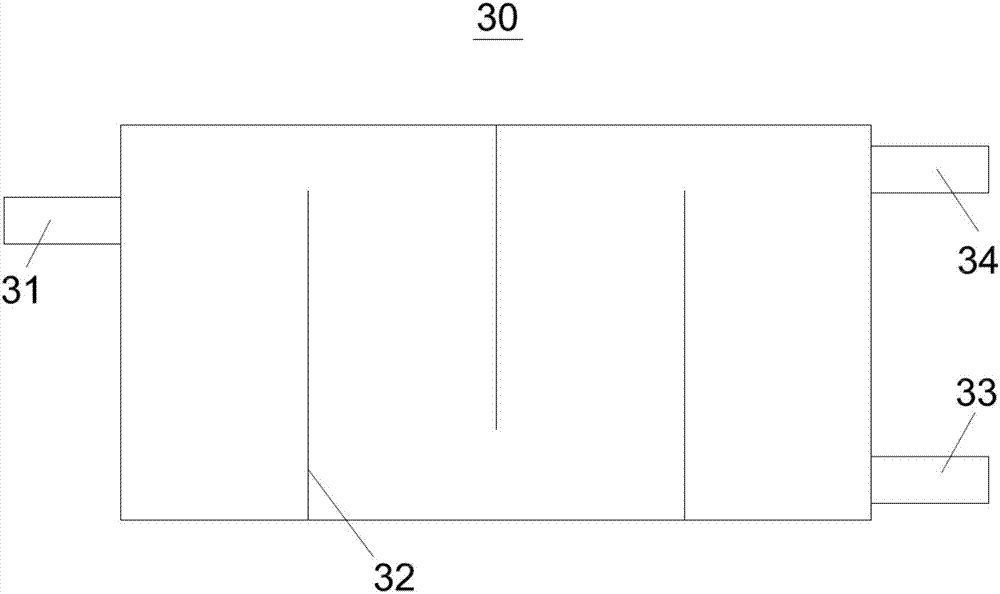

[0036] Step 2, the pulverized powder is transported to the distillation tower 10 by the elevator, and the mixture of steam and ginger oil is discharged after distillation; the distillation tower 10 adopts a kettle structure, including a kettle body 11, and the middle part of the kettle body 11 is provided with a The sieve plate type charging partition 13, the bottom of the kettle body 11 is provided with an air inlet 12, and the top of the kettle body 11 is provided with an exhaust outlet 17 and is provided with a mesh baffle for preventing ginger particles from being discharged from the exhaust outlet 17. Plate 16, the kettle body 11 between the mesh baffle plate 16 and the charging partition 13 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com