Construction method for ultra-shallow-buried underground excavation subway station construction through flat-roof and upright-wall pipe curtain structure

A construction method and technology for subway stations, which are used in underground chambers, earth-moving drilling, wellbore lining, etc., can solve the problems of slow construction progress, weak lateral stiffness and bearing capacity of pipe curtains, and low space utilization, and increase the horizontal The effect of bearing capacity, increasing space utilization, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0042] The invention provides a construction method for constructing an ultra-shallow underground excavation subway station, which adopts a flat roof and straight wall pipe curtain structure, and specifically includes the following construction steps:

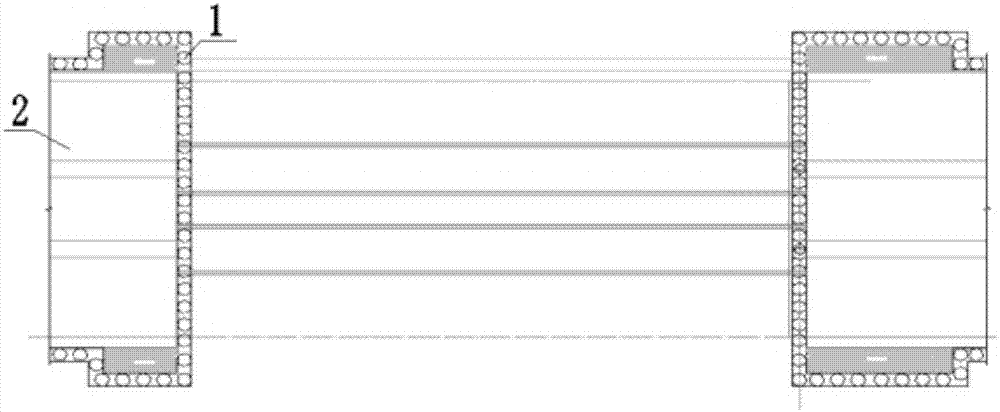

[0043] Step 1: Construct enclosure piles 2 around the working well 1. After the enclosure piles reach strength, excavate the working well and build a pipe jacking construction platform. See figure 1 .

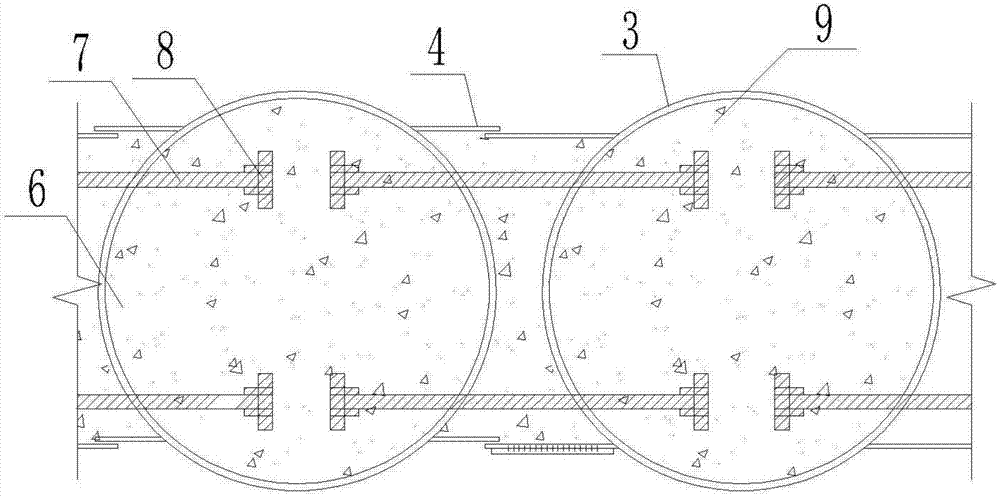

[0044] Step 2: Process the construction steel pipe 3 in the processing plant, weld the flange plate 4 at the design position on both sides of the steel pipe, and open the reserved bolt hole and reserved groove 6 at the design position, see figure 2 .

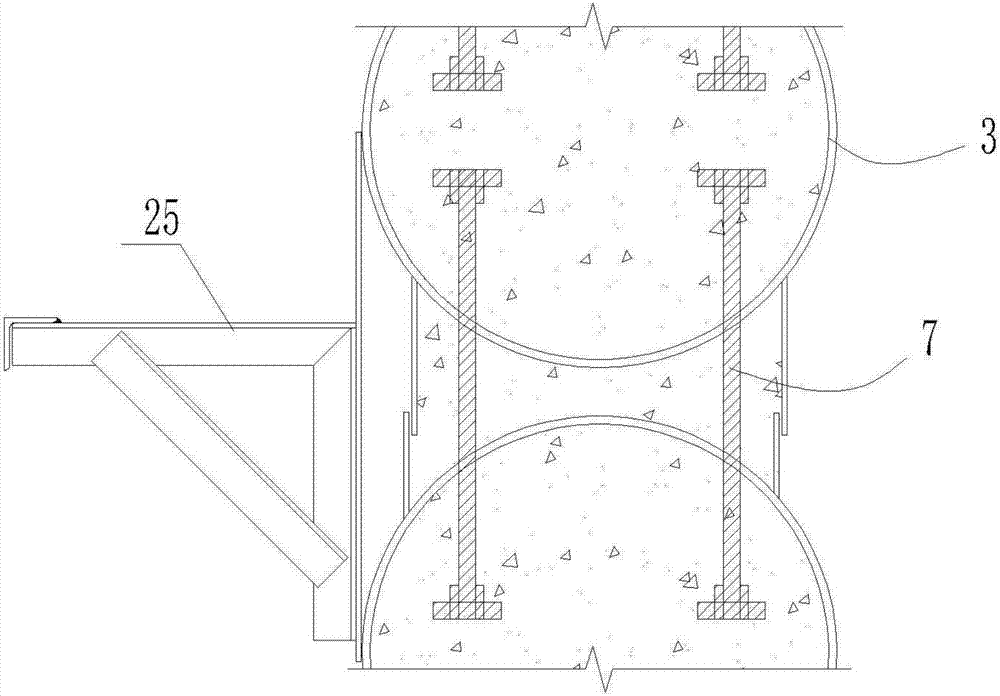

[0045] Step 3: Use the jacking method to construct the No. 1 to No. 24 top steel pipes and No. 25 and No. 34 side steel pipes in the undergrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com