A high and low temperature double body vacuum hot pressing sintering furnace

A technology of vacuum hot pressing sintering and sintering furnace, which is applied in the direction of furnace, charge, muffle furnace, etc. It can solve the problems of high input cost and different temperature control accuracy, and achieve the effect of saving investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

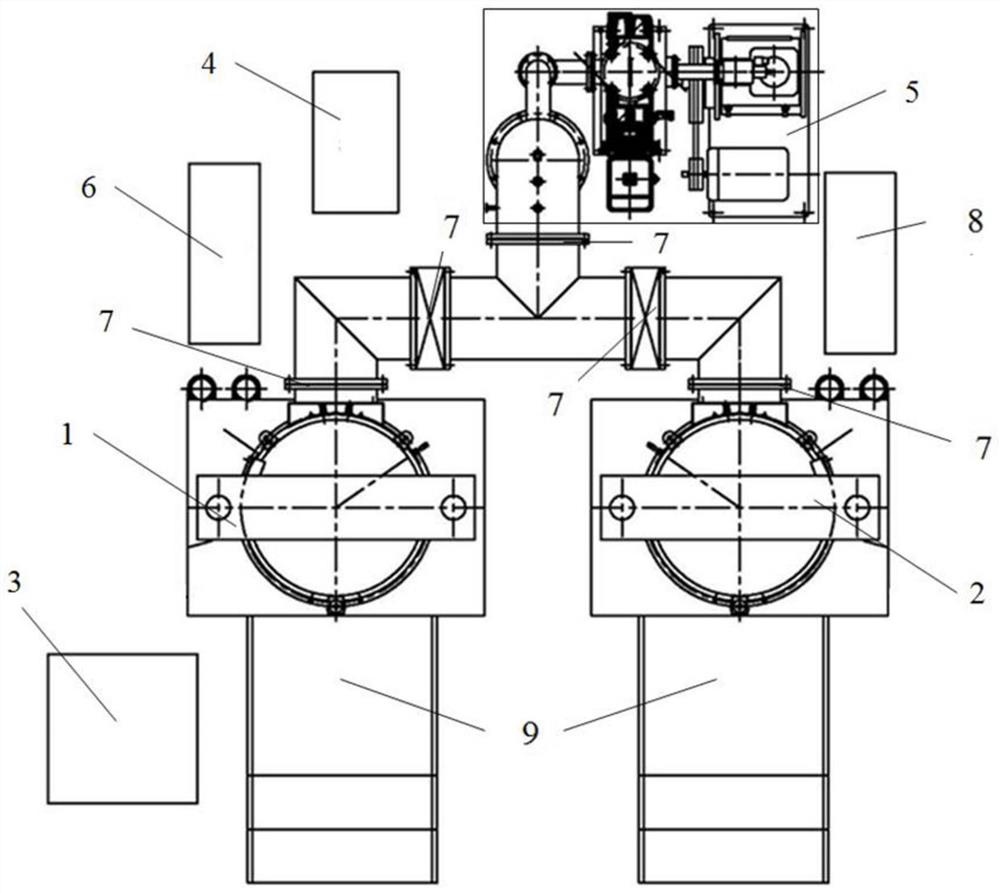

[0034] A high-low temperature dual-body vacuum hot-pressing sintering furnace of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

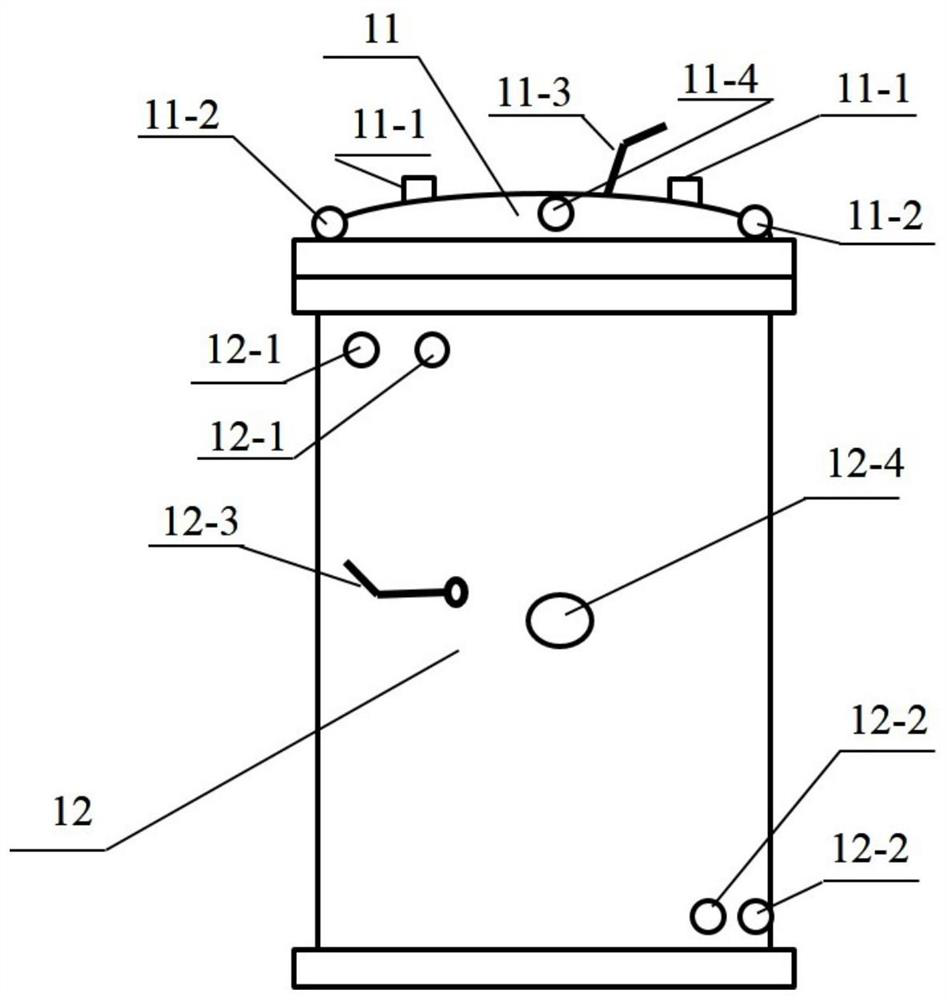

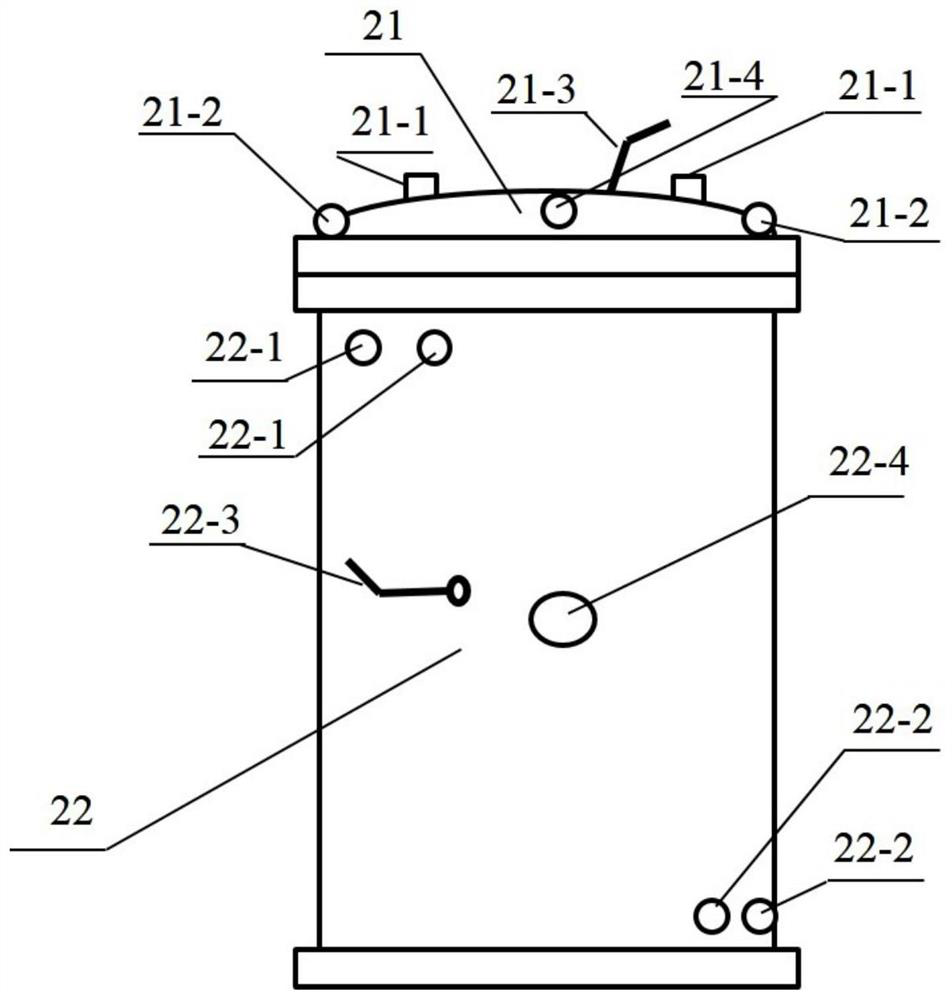

[0035] In the embodiment of the present invention, the high-low temperature dual-body vacuum hot-pressing sintering furnace includes a furnace body 1 in a high-temperature zone. The heating system adopts a graphite heater, which is connected in a cylindrical shape. It ensures the best temperature uniformity and uniform heating of the workpiece, and can be replaced at any time; the furnace body 2 in the low temperature zone, the heating system adopts nickel-chromium resistance band heater, the maximum heating temperature is 1200 ℃, and it is symmetrically distributed outside the uniform temperature zone to ensure The best temperature uniformity and uniform heating of the workpiece, and easy maintenance and replacement of the heating element; furnace bodies 1 and 2 are both do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com