Flexible perovskite solar cell and preparation method thereof

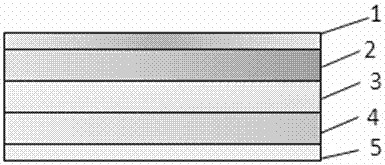

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of poor stability of the light-absorbing layer, low flexibility of organic-inorganic hybrid perovskite, and low electron mobility, so as to reduce preparation costs and improve photoelectric conversion Efficiency and stability, and the effect of expanding the absorption spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] This embodiment includes the following steps:

[0104] (1) Spin-coat the black phosphorus dispersion on a transparent and flexible conductive substrate to form a black phosphorus electron transport layer, and bake it at 100°C for 5 minutes to form a black phosphorus electron transport layer;

[0105] The flexible conductive substrate is a thin film layer formed by polyethylene terephthalate (PET) with a pre-set circuit;

[0106] The spin coating speed is controlled at 3000rpm, and the spin time is controlled at 50s;

[0107] The solvent of described black phosphorus dispersion liquid is dehydrated alcohol;

[0108] The solid-to-liquid ratio of the black phosphorus dispersion (i.e. the mass ratio of black phosphorus to solvent)=1:4;

[0109] The number of black phosphorus layers in the black phosphorus electron transport layer is 7, and the film thickness of the electron transport layer is 350nm.

[0110] (2) Black phosphorus / CsPbBr 3 The composite dispersion was for...

Embodiment 2

[0122] This embodiment includes the following steps:

[0123] (1) Spin-coat the black phosphorus dispersion on a transparent and flexible conductive substrate to form a black phosphorus electron transport layer, and bake it at 100°C for 5 minutes to form a black phosphorus electron transport layer;

[0124] The flexible conductive substrate is a thin film layer formed by polyethylene terephthalate (PET) with a pre-set circuit;

[0125] The spin coating speed is controlled at 4500rpm, and the spin time is controlled at 60s;

[0126] The solvent of described black phosphorus dispersion liquid is dehydrated alcohol;

[0127] The solid-to-liquid ratio of the black phosphorus dispersion (i.e. the mass ratio of black phosphorus to solvent)=2:5;

[0128] The number of black phosphorus layers in the black phosphorus electron transport layer is 8, and the film thickness of the electron transport layer is 400nm.

[0129] (2) Black phosphorus / CsSnBr 3The composite dispersion was form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com