Compound sintered compact cutting tool and compound sintered compact cutting tool with coated surface

A technology of cutting tools and sintered bodies, which is applied in the direction of manufacturing tools, workpieces, drilling accessories, etc., can solve problems such as chipping, insufficient strength, toughness, and insufficient heat cracking resistance, and achieve the effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] In Example 1, a tool having a rake face made of WC-based cemented carbide having a polygonal planar shape formed on only one side of the TiCN-based cermet will be described.

[0090] First, WC-based cemented carbide raw material powders having a compounding composition shown in Table 1 and an average particle diameter of 0.5 to 3 μm were prepared.

[0091] Then, TiCN-based cermet raw material powder having a compounding composition shown in Table 2 and having an average particle diameter of 0.5 to 3 μm was prepared.

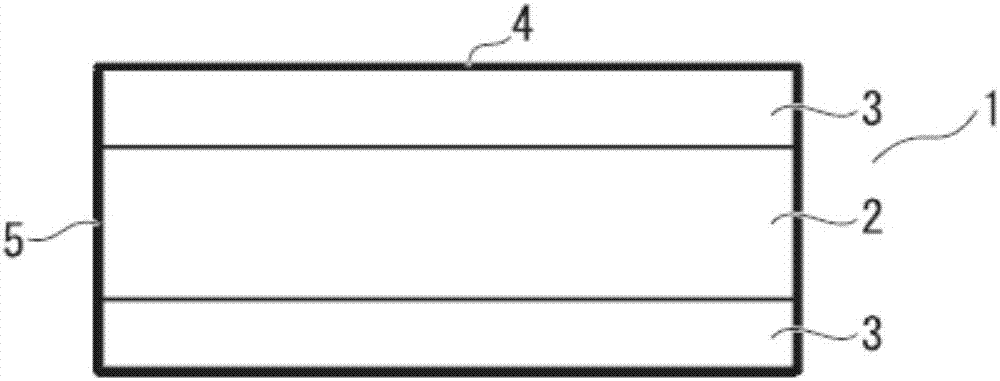

[0092] The above-mentioned WC-based cemented carbide raw material powder and TiCN-based cermet raw material powder were stacked and pressed with a mold for the raw materials of the combined ISO blade shape SNMN120408 shown in Table 3, and composite molded bodies 1 to 6 were produced.

[0093] Next, the composite molded bodies 1 to 6 were sintered to produce composite sintered bodies 1 to 6 .

[0094] In any case, the sintering conditions were as follows. ...

Embodiment 2

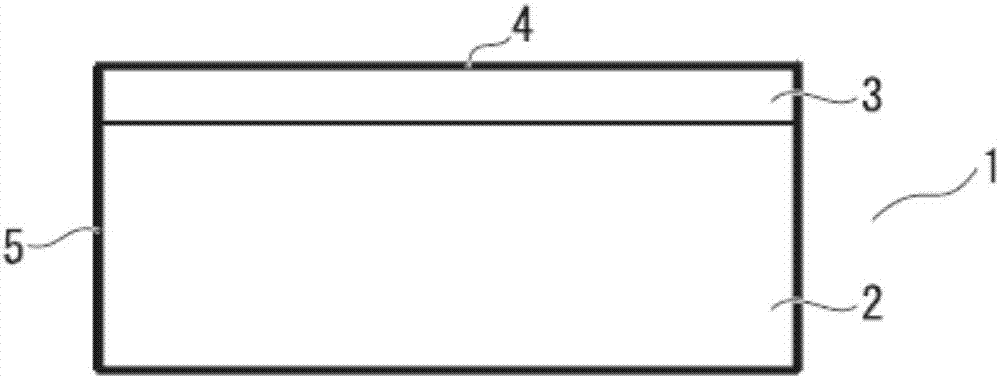

[0148] In Example 1, the planar shape of the rake face is a polygonal shape, and the tool in which the rake face made of WC-based cemented carbide is formed only on one side of the TiCN-based cermet has been described, but as Example 2, Next, a tool having rake faces formed on both surfaces of the TiCN-based cermet will be described.

[0149] In the same manner as in Example 1, WC-based cemented carbide raw material powders with an average particle size of 0.5 to 3 μm in the compounding composition shown in Table 1 and WC-based cemented carbide raw material powders with an average particle size in the range of 0.5 to 3 μm in the compounding composition shown in Table 2 were prepared. TiCN-based cermet raw material powder.

[0150] From the upper and lower surfaces of the above-mentioned TiCN-based cermet raw material powder, WC-based cemented carbide raw material powder is used to form a sandwich state, and the raw material of the ISO blade shape SNMN120408 shown in Table 8 is...

Embodiment 3

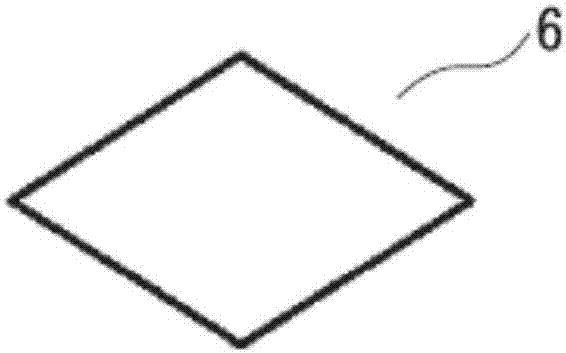

[0164] Next, in Example 3, a tool whose rake face has a circular planar shape will be described.

[0165] WC-based cemented carbide raw material powders with the compounding composition shown in Table 1 and an average particle size of 0.5 to 3 μm and TiCN-based cermet raw material powders with the compounded composition shown in Table 2 and an average particle size of 0.5 to 3 µm were prepared.

[0166] The above-mentioned WC-based cemented carbide raw material powder and TiCN-based cermet raw material powder were stacked and pressed with a mold for the raw materials of the combination ISO blade shape RNMG120400 shown in Table 11, and composite molded bodies 21-24 were produced.

[0167] Furthermore, the produced composite molded bodies 23 and 24 are composite molded bodies in which the WC-based cemented carbide raw material powder is sandwiched from the upper and lower surfaces of the TiCN-based cermet raw material powder.

[0168] Next, the composite molded bodies 21 to 24 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com