Device and method for treating waste gas through high-energy ultraviolet light catalysis cooperated with ozone oxidation

An ozone oxidation and waste gas treatment device technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of secondary pollution operation costs, low waste gas treatment efficiency, etc., and achieve light weight and low equipment energy consumption. , the effect of small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

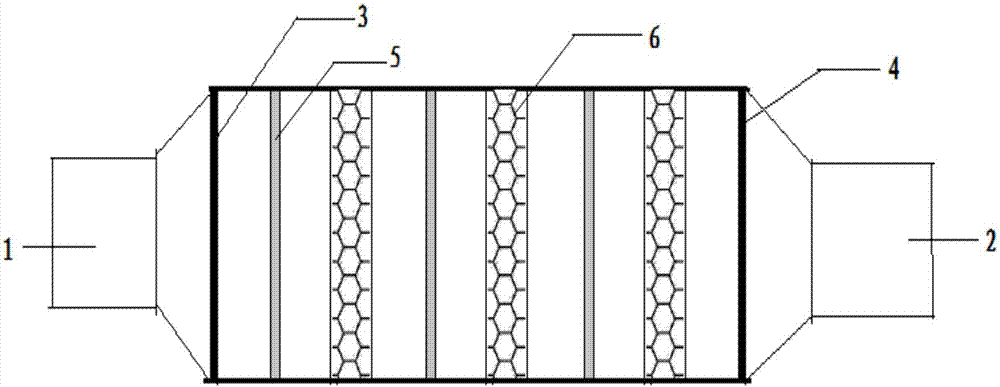

[0034] Embodiment 1 provides a waste gas treatment device for microwave stepless ultraviolet photocatalysis and ozone oxidation oxidation, such as figure 1 As shown, wherein, 1 is the air inlet, 2 is the air outlet, 3 is the first metal mesh, 4 is the second metal mesh, 5 is the photocatalyst layer, 6 is the ozone oxidation layer, wherein the first metal mesh and the second Metal nets are respectively arranged at the air inlet and the air outlet of the device. The photocatalyst layer and the ozone oxidation layer are provided with 3 cycles in the barrel of the device. That is, along the direction of gas flow, a photocatalyst layer, an ozone oxidation layer, a photocatalyst layer, an ozone oxidation layer, a photocatalyst layer, and an ozone oxidation layer are provided. The first metal mesh and the second metal mesh are respectively provided with nanoscale TiO 2catalyst of light. The nanoscale TiO 2 The photocatalyst is 50nm TiO 2 , purchased from Nanchang Chuangjie Techn...

Embodiment 2

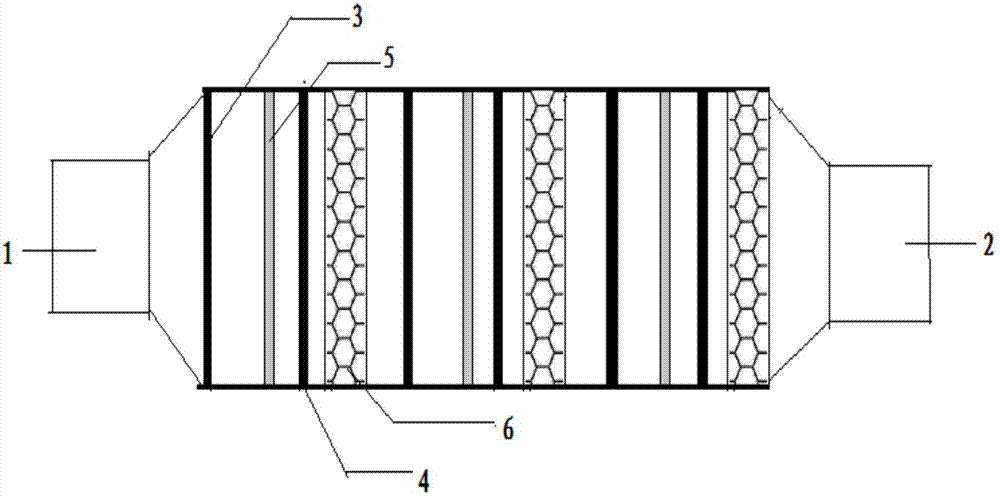

[0041] Embodiment 2 provides a waste gas treatment device for microwave stepless ultraviolet photocatalysis and ozone oxidation oxidation, such as figure 2 shown. Wherein 1 is an air inlet, 2 is an air outlet, 3 is a first metal mesh, 4 is a second metal mesh, 5 is a photocatalyst layer, and 6 is an ozone oxidation layer. The difference between Embodiment 2 and Embodiment 1 is that, in Embodiment 2, metal meshes are arranged before and after each photocatalyst layer, which are the first metal mesh and the second metal mesh respectively. That is, the first metal mesh, the photocatalyst layer, the second metal mesh and the ozone oxidation layer are sequentially arranged along the airflow direction, and this sequence is repeated three times. The wavelengths of the microwave electrodeless ultraviolet light are respectively set to 185nm, 253.7nm and 185nm, and then the same method as in Example 1 is used for measurement. The test shows that the removal rate of benzene is as high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com