A method for preparing graphene by using electrostatically accelerated medium flow exfoliation

An electrostatic acceleration, graphene technology, applied in the field of graphene material preparation technology, can solve the problems of difficult large-scale industrial production, high cost, product pollution, etc., and achieve the effects of controllable defects, high conductivity, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing graphene by using electrostatically accelerated medium flow exfoliation. The detailed process flow is: firstly dissolve the sodium salt in deionized water with mechanical stirring, add layered crystal graphite material, mechanically stir and ultrasonic for a certain period of time, carbon powder Evenly suspend in the solution to form graphite slurry; then turn on the spray device and feeding device to spray the prepared graphite slurry on the discharge electrode of the corona device under high pressure, and form tiny mist droplets at the tip of the needle, and at the same time, the mist slurry particles are Corona, negative charges quickly gather on the surface of graphite particles, and the tiny mist droplets are finally split into individual graphite particles under the action of static electricity. The electrostatic repulsion between charges exceeds the interlayer gap of graphite particles and further increases, becoming expandable graphite parti...

Embodiment 2

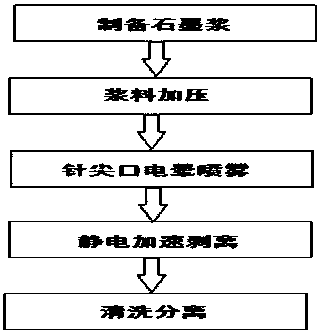

[0035]A method for preparing graphene by using electrostatic accelerated medium flow exfoliation, the detailed process flow is as follows figure 1 : First, the sodium salt is mechanically stirred and dissolved in deionized water, and layered crystalline graphite material is added. After mechanical stirring and ultrasonication for a certain period of time, the carbon powder is evenly suspended in the solution to form a graphite slurry; then the spray device and the feeding device are opened to prepare The high-pressure graphite slurry is sprayed at high pressure above the discharge electrode of the corona device, and tiny mist droplets are formed at the tip of the needle. Under the action, it finally splits into individual graphite particles, and the electrostatic repulsion between charges exceeds the interlayer gap of graphite particles to further increase, becoming expandable graphite particles. Further use the medium flow accelerated by the electrostatic accelerator to peel ...

Embodiment 3

[0042] A method for preparing graphene by using electrostatically accelerated medium flow exfoliation. The detailed process flow is: firstly dissolve the sodium salt in deionized water with mechanical stirring, add layered crystal graphite material, mechanically stir and ultrasonic for a certain period of time, carbon powder Evenly suspend in the solution to form graphite slurry; then turn on the spray device and feeding device to spray the prepared graphite slurry on the discharge electrode of the corona device under high pressure, and form tiny mist droplets at the tip of the needle, and at the same time, the mist slurry particles are Corona, negative charges quickly gather on the surface of graphite particles, and the tiny mist droplets are finally split into individual graphite particles under the action of static electricity. The electrostatic repulsion between charges exceeds the interlayer gap of graphite particles and further increases, becoming expandable graphite parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com