Fiber reinforced cement material

A cement material and fiber-reinforced technology, which is applied in the field of fiber-reinforced cement materials, can solve the problems of occupying the actual use space, poor thermal insulation and sound insulation performance, and high labor intensity, and achieve the goal of reducing weight, thickness, and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] A fiber-reinforced cement material, including the following raw materials and weight fractions: 7%-9% of water, 24%-30% of Portland cement, 8%-12% of slag powder, 40%-50% of quartz sand, steel fiber 1%-2%, silica fume 1.5%-3.5%, polystyrene insulation particles 1.5%-2.0%, expansion agent 1%-3%, mixed with 0.3%-0.6% admixture, the admixture is to reduce Water agent, defoamer, its weight percent is: water reducer 0.15%-0.30%, defoamer 0.05%-0.10%, said admixture is respectively: water reducer is polycarboxylic acid, defoamer is poly ether.

[0010] This product has good compressive strength, low density and excellent sound insulation performance. See Table 1 below for details:

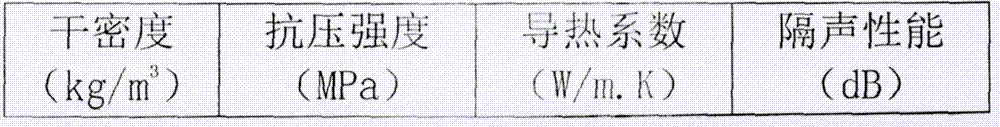

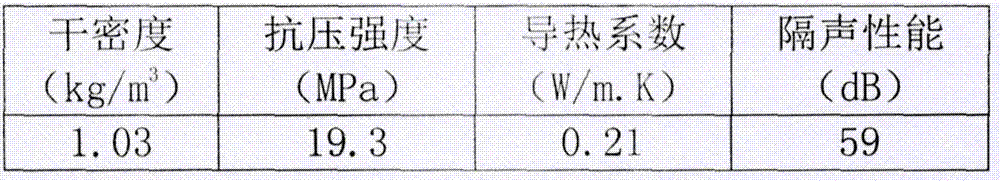

[0011] Table 1 Technical index of the present invention

[0012]

[0013]

Embodiment 2

[0015] A fiber-reinforced cement material, including the following raw materials and weight fractions: 7.89% of water, 25.96% of Portland cement, 11.12% of slag powder, 45.82% of quartz sand, 1.58% of steel fiber, 3.16% of silica fume, polystyrene insulation Granules 1.78%, expansion agent 2.37%, water reducer 0.26% and defoamer 0.08%.

[0016] This product has good compressive strength, low density and excellent sound insulation performance. See Table 2 below for details:

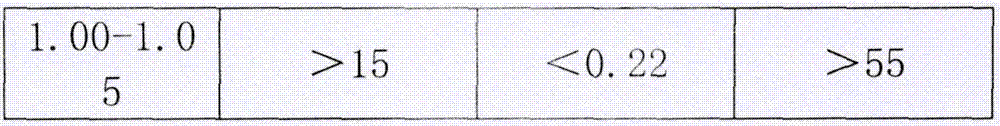

[0017] Table 2 Measured technical indicators

[0018]

[0019] The invention provides a fiber-reinforced cement material, whose compressive strength is the same as that of ordinary concrete, and whose density is only 40% of that of concrete, which can effectively reduce the weight of the exterior wall of a prefabricated building and reduce the labor intensity during molding and maintenance. Save on shipping costs. At the same time, its thermal insulation and sound insulation performance is superior. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com